A customer of mine, a luthier, needed a guide bearing that mached the diameter of a certain router bit. It needed to fit over the 8mm shank of the bit and have 21,5mm OD.

Such a bearing is not availible, you can only get one with 8mm bore and 22mm outer diameter.

I needed a simple way to get the diameter of the outer race down - First idea was to turn it down with a CBN insert, but in the end I settled for cylindrical grinding on the surfacegrinder.

There is also a video showing the whole process:

Resizing a ball bearing

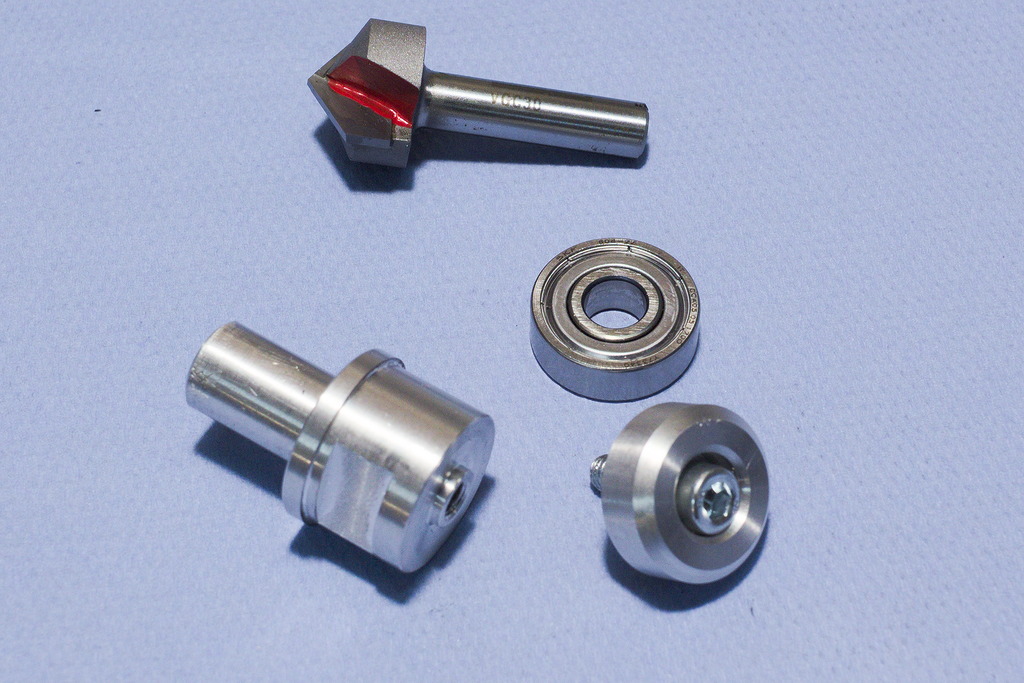

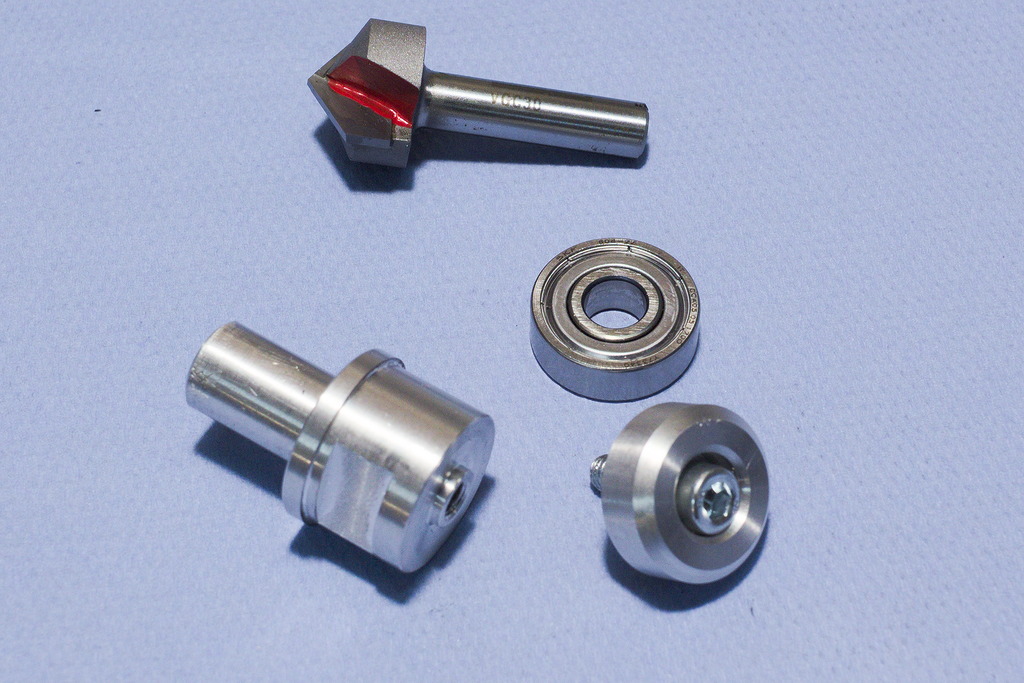

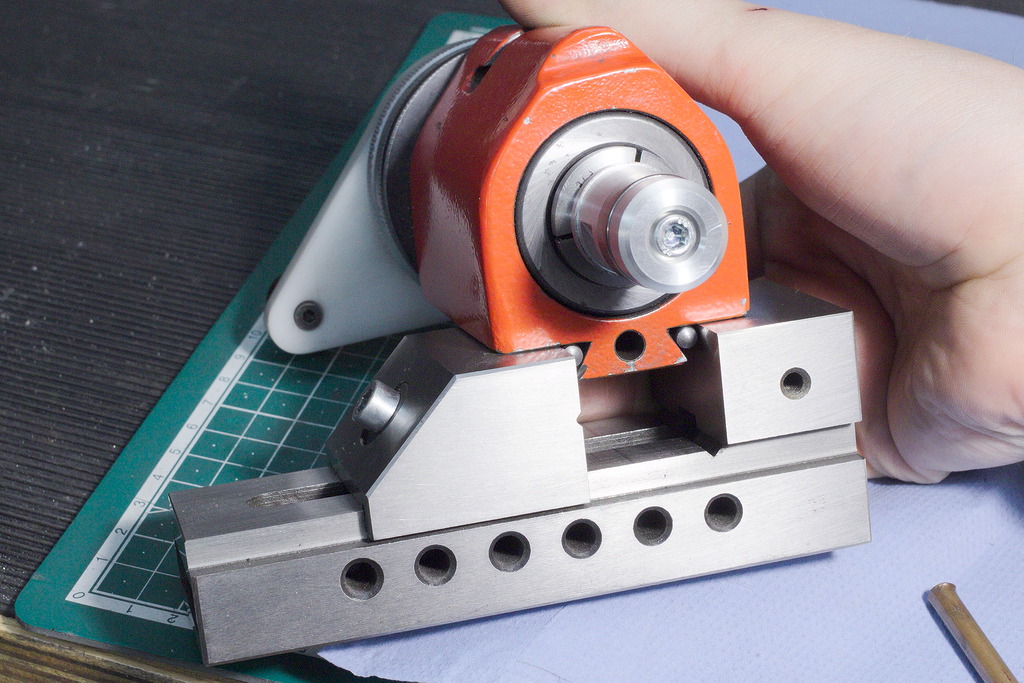

An arbor was turned out of aluminium that had an 7,8mm register in the center and 21,4mm outer diameter, along with a heavy washer. Those parts together allowed me to clamp the bearing in between and adjust it for almost zero runout.

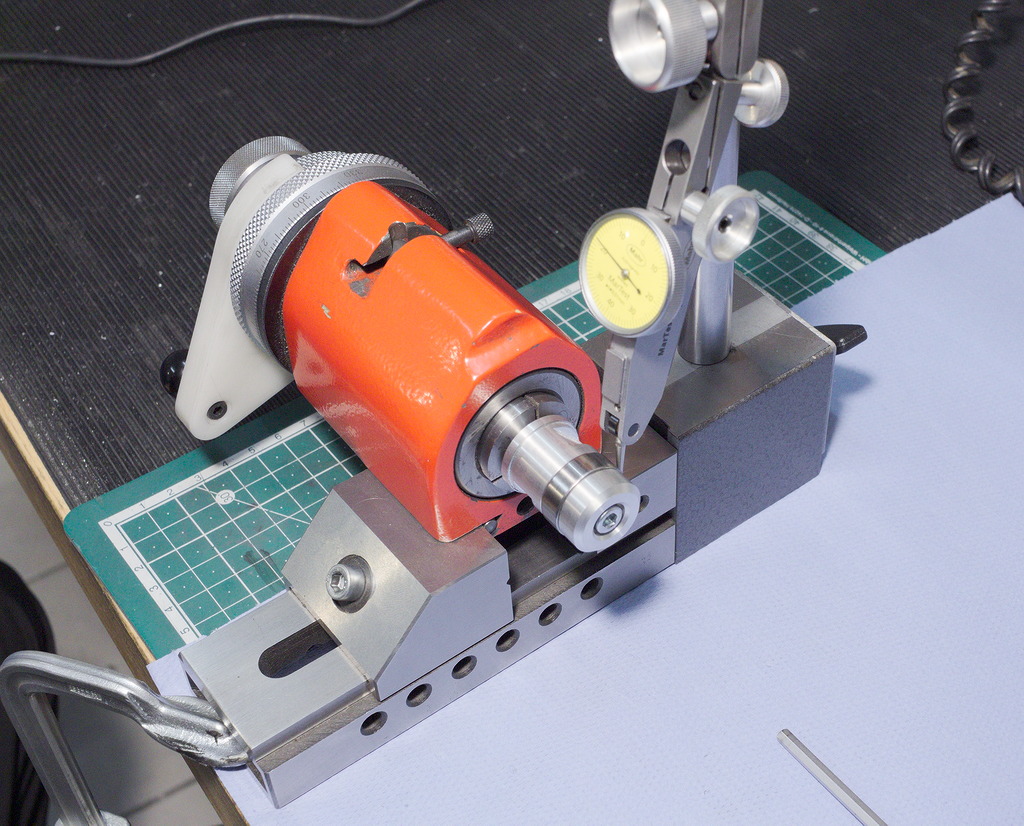

I am using the workhead of my d-bit grinder as a spin fixture. It has preloaded bearings and takes collets, so its quite well suited for that purpose. Here I am centering the bearing on the arbor. The arborscrew was semi-tightened and the bearing knocked true with a small piece of brass until the 2/1000mm indicator showed almost no movement.

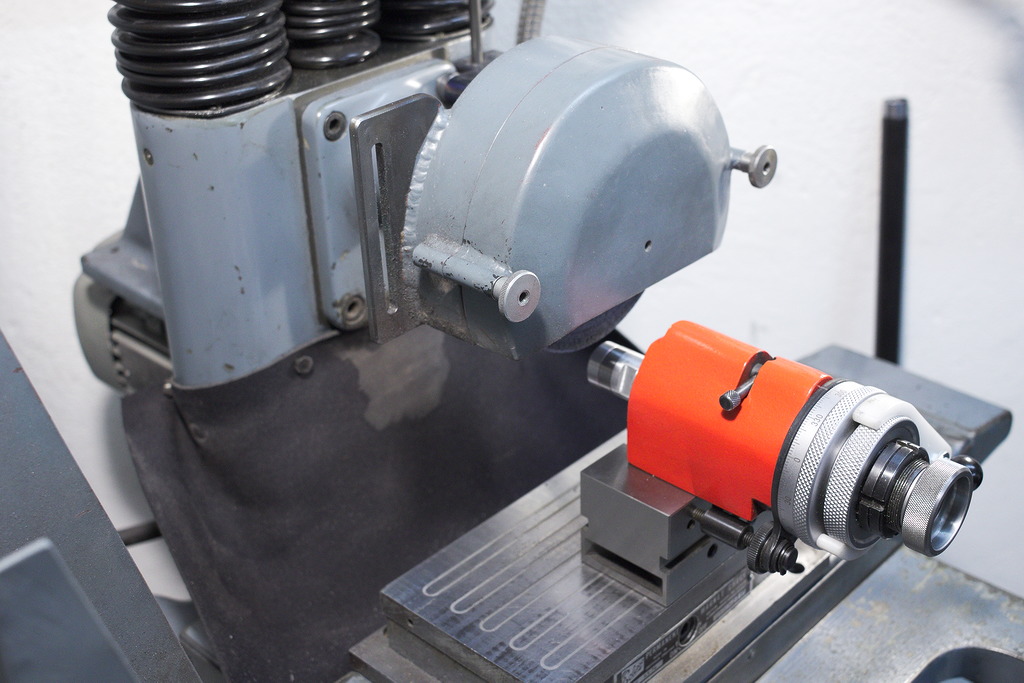

Thats how the workhead with its dovetailmount is held in the grinding vice, with two pins:

Grinding the bearing race was very simple, holding tolerance was not a problem at all. Care had to be taken not to overheat it, in that case it would have been very easy to overshoot on the diameter.

The finished bearing on the left, a stock bearing on the right, comparing the surface finish:

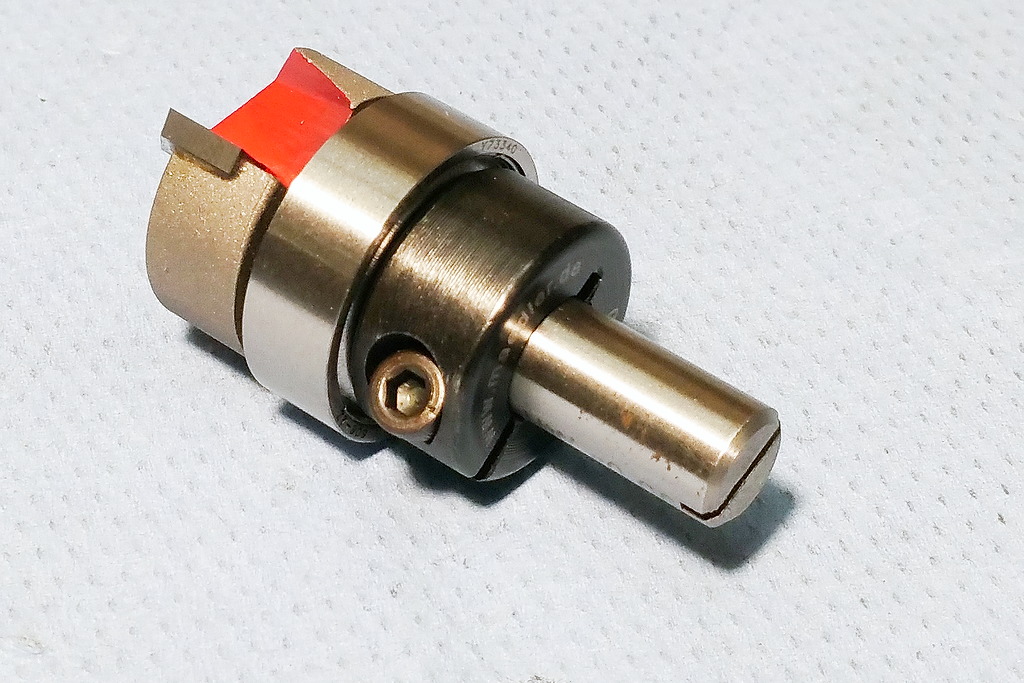

The router bit with the guide bearing and a shaft collar behind it to hold it in place: