Box parallel/Setup cube

September 2016

Tom Lipton (We all know him, right?) showed in one of his videos a very neat designed setup block that was fabricated out of two pieces of heavy sheet metal and some square tubing.

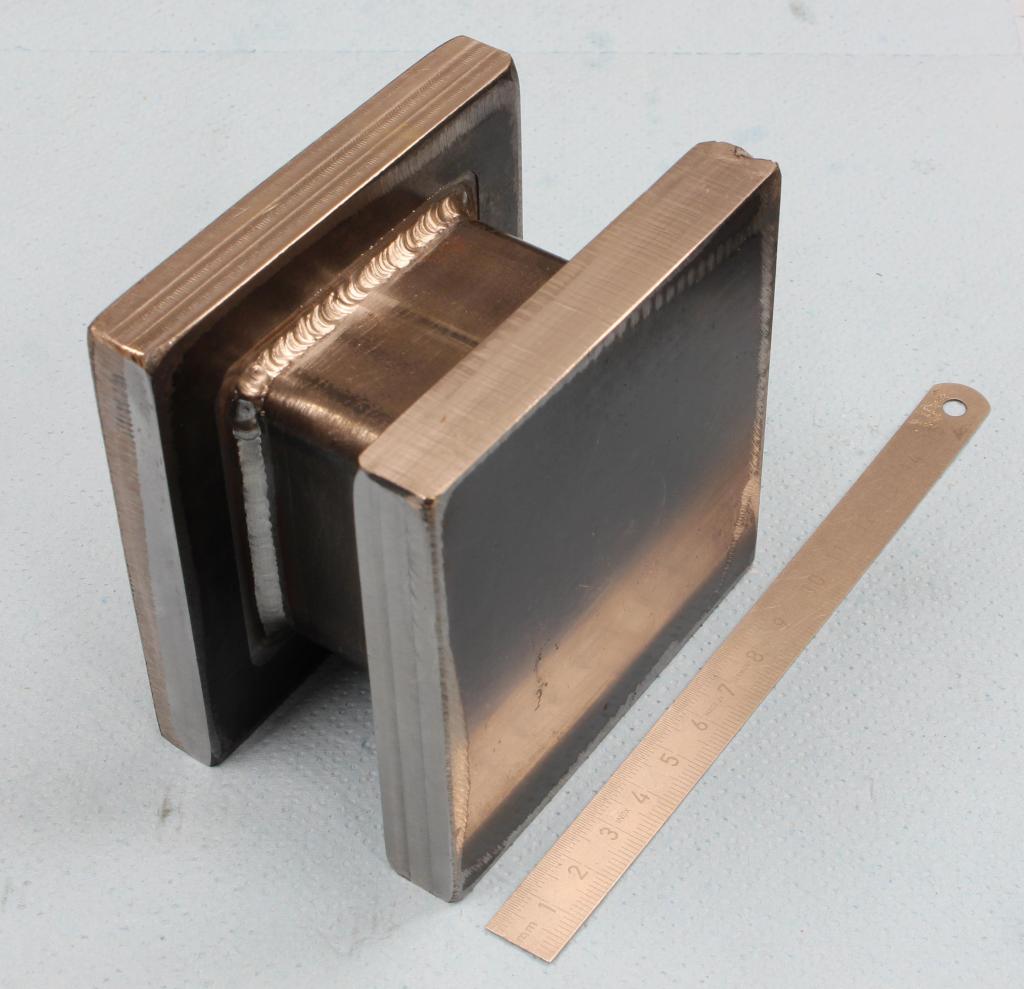

I liked the design very much, so I made my own. I ordered some 15mm mild steel sheet metal from ebay (Plasmacut to 110x110mm) and I had a piece of 60x60x5mm tubing left over from another project.

After squaring the parts up more or less I did the weld preparation and put it all together by Tig welding:

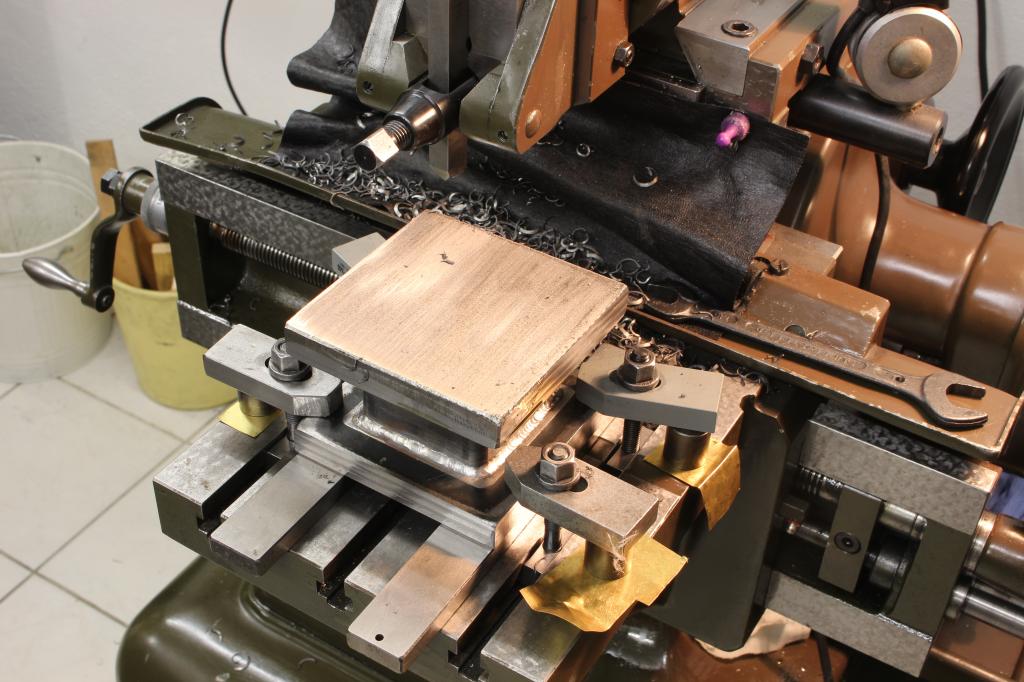

Then I clamped it up on the shaper and faced the big main faces. It took me a few passes with flipping the part over between them to get everything nice and even:

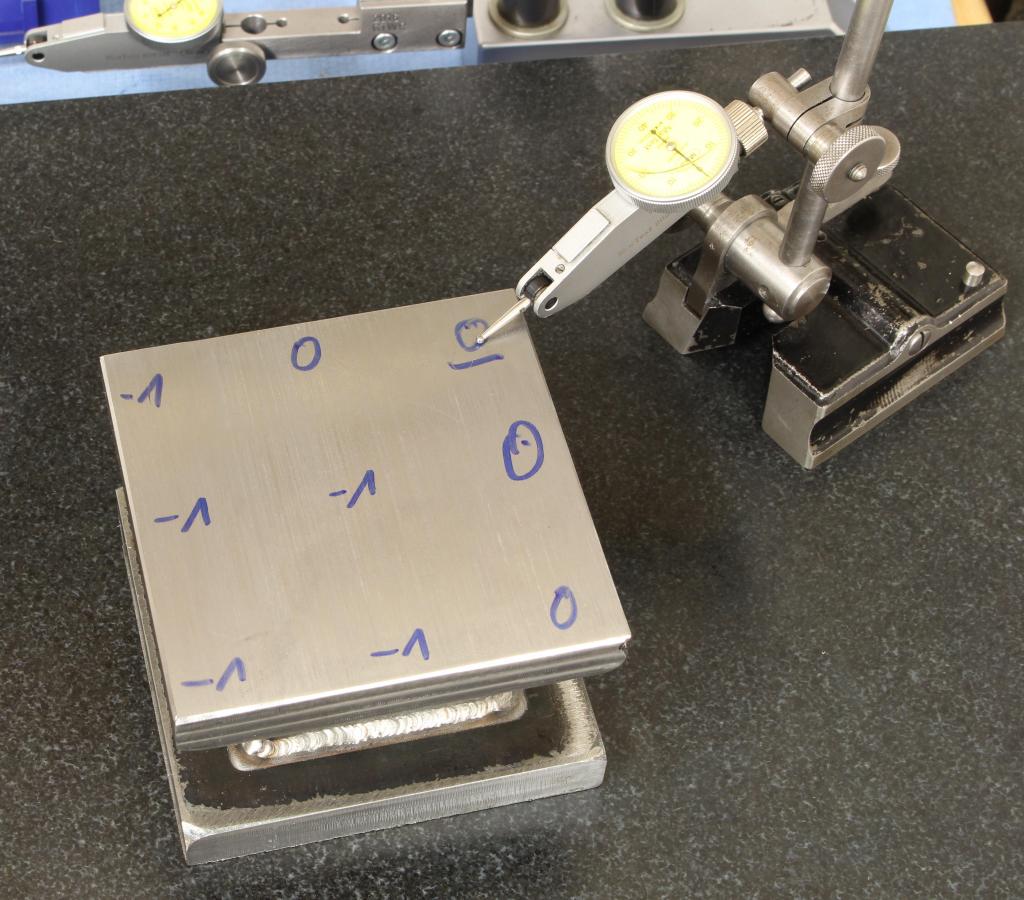

Thats the error in parallelism that I got in the end, 1/100mm or less. I did not bother to put the part on the surface grinder as I intend this to be a everyday tool. If I need a more precise setup block I have my handscraped toolmakers block.

I did also not bother to stress relief the part. As long as you start by roughing it out and do sequentialy lighter finishing cuts, you will end up with a stable part.

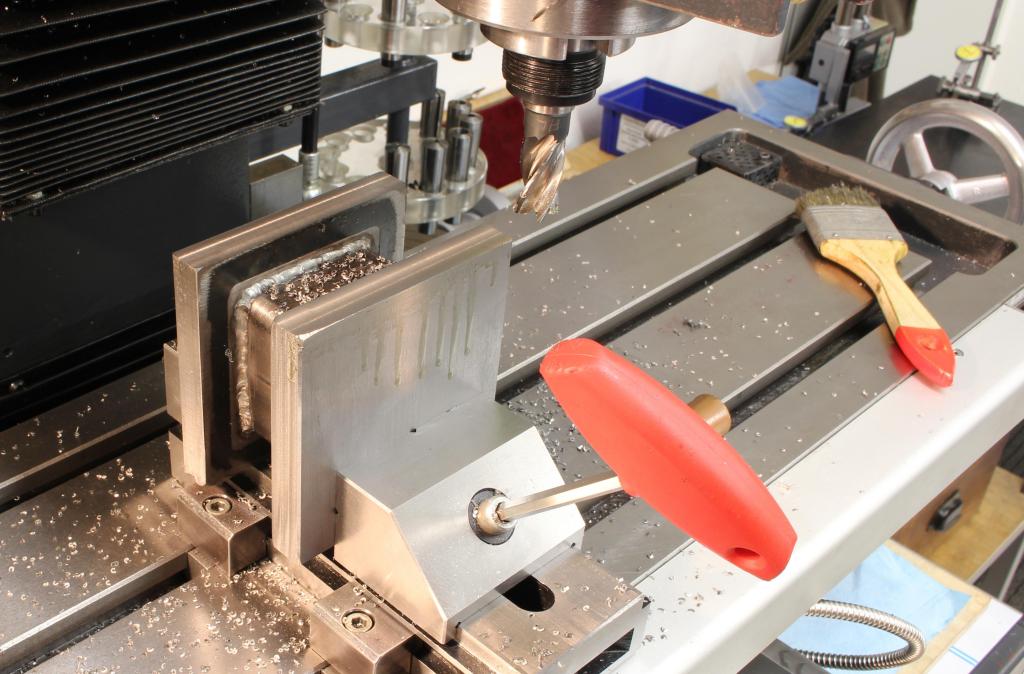

The setup to machine the narrow faces, I opted for face milling as it is very easy to achieve good precision that way - The cutting preassure is very low and you are not likely to deflect the part, the machine or the tool with light facing cuts:

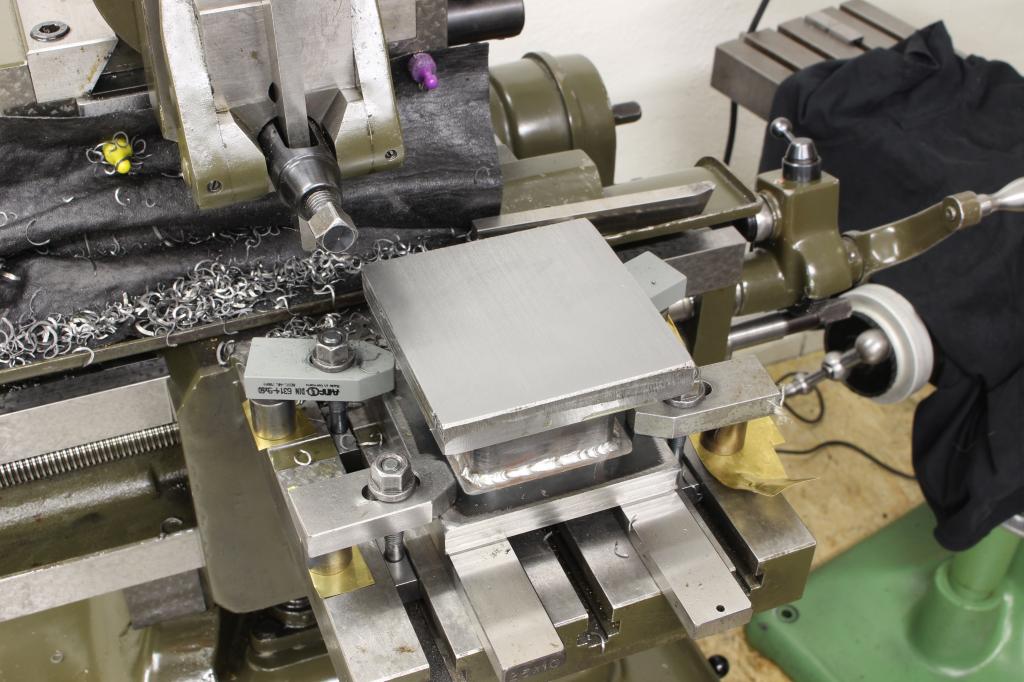

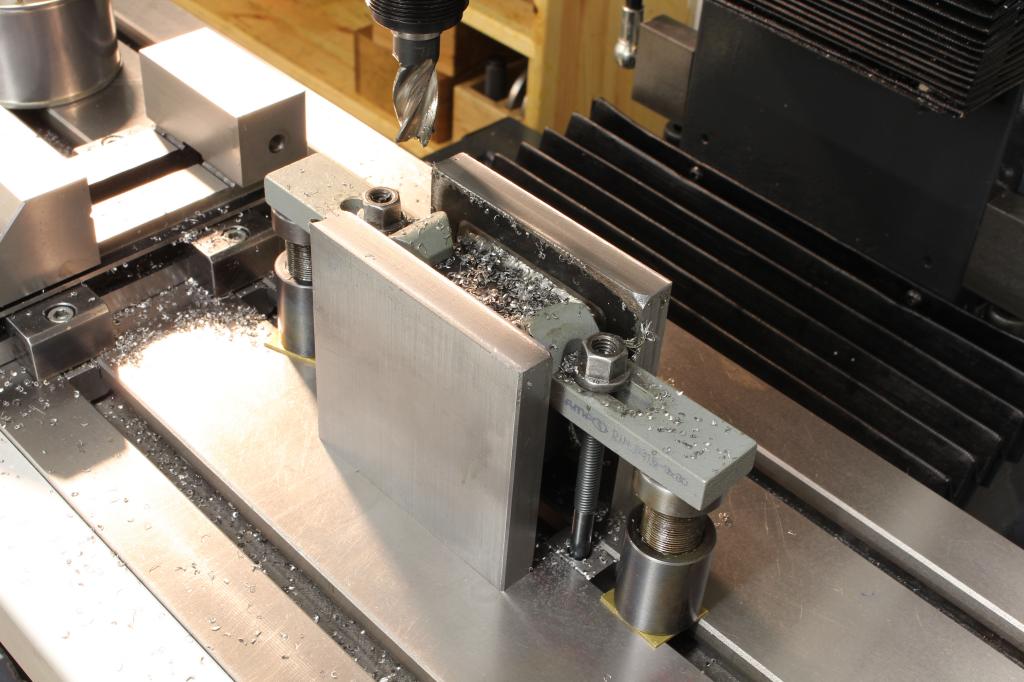

Machining the opposing side parallel, the part is held directly to the table:

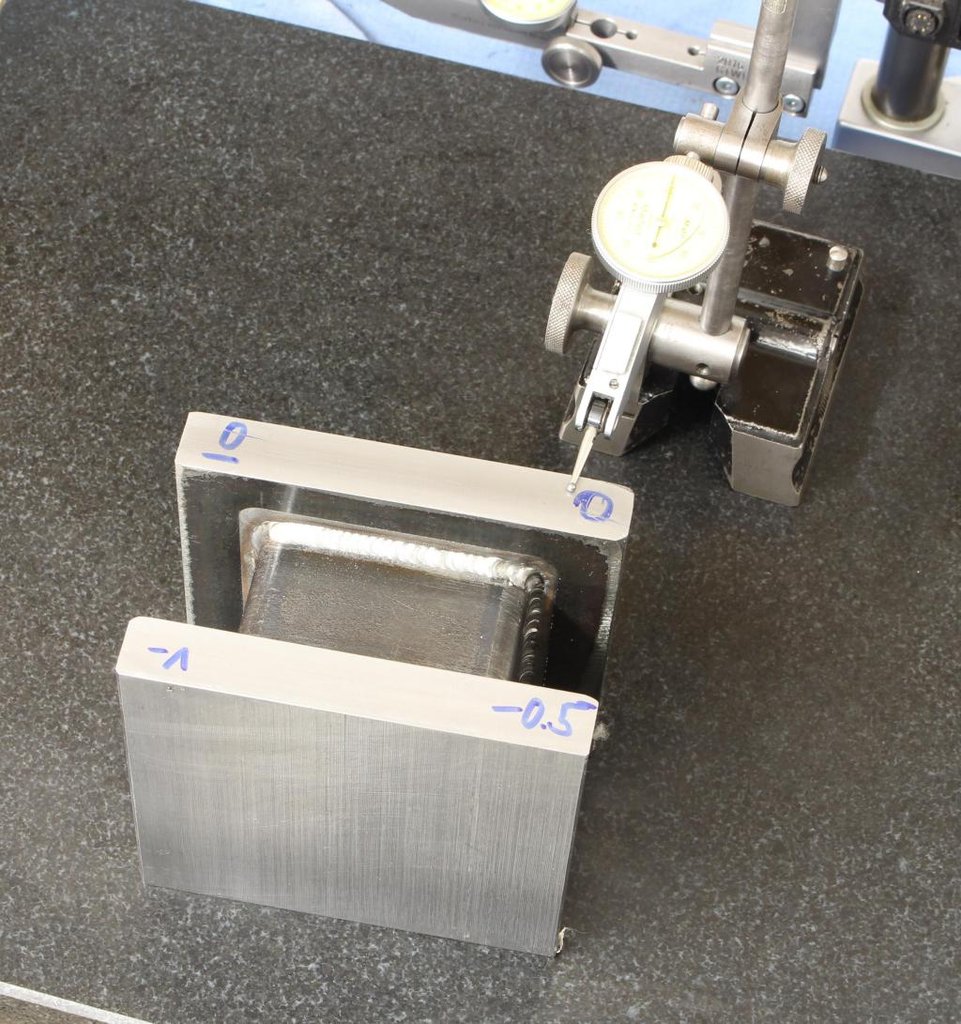

Checking the parallelism, numbers are again in 1/100mm:

Setup to machine the faces square to the two machined before. The Starrett combination square is suprisingly accurate:

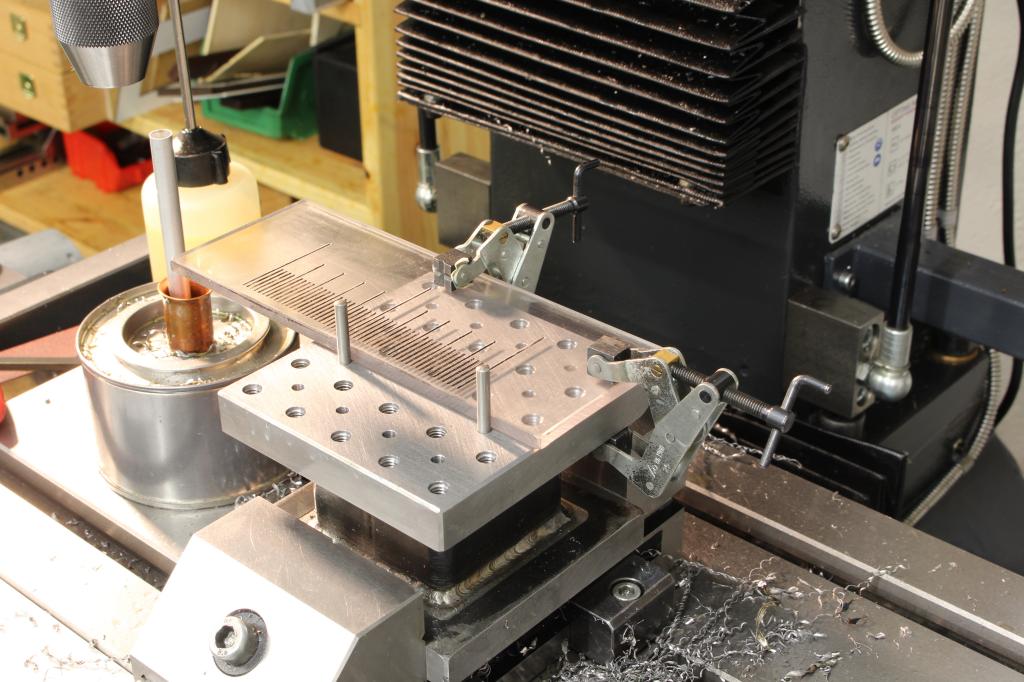

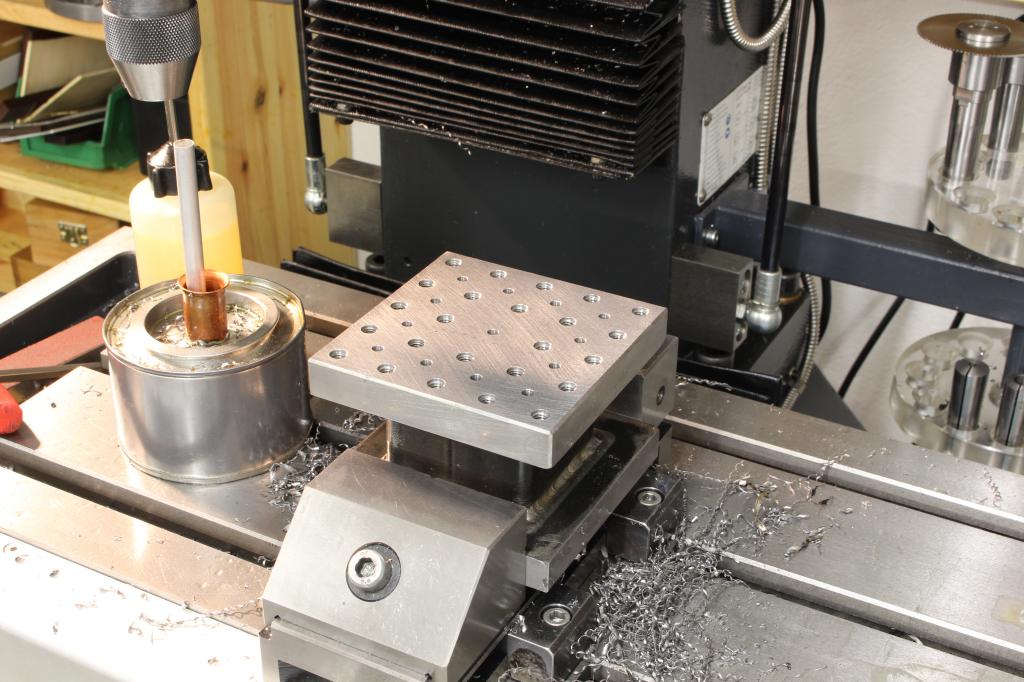

Drilling and tapping a grid of M6 threaded holes and 4H7 precision holes for dowel pins:

The block came out square and parallel in all directions to 1/100mm (or better), so its absolutely suitable for pretty much all tasks on the milling machine or the shaper.

And what can it be used for?

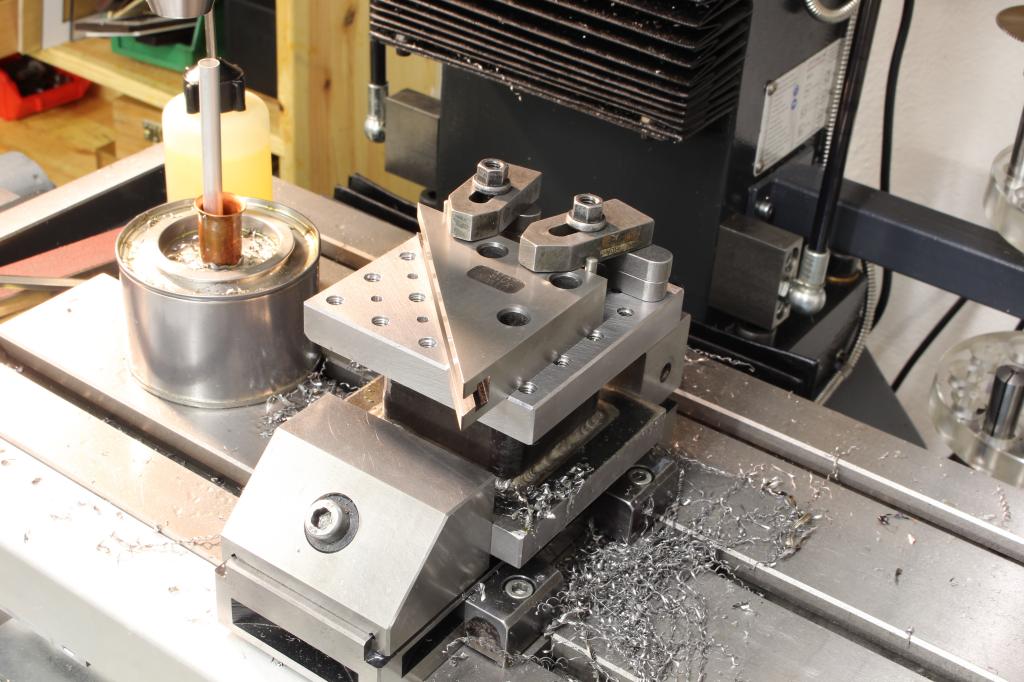

In combination with some clamps for holding the part and some 4mm dowel pins for alignment it makes fixturing for small production runs very easy:

The overhanging plates allow to use small c-clamps or kant-twist-clamps: