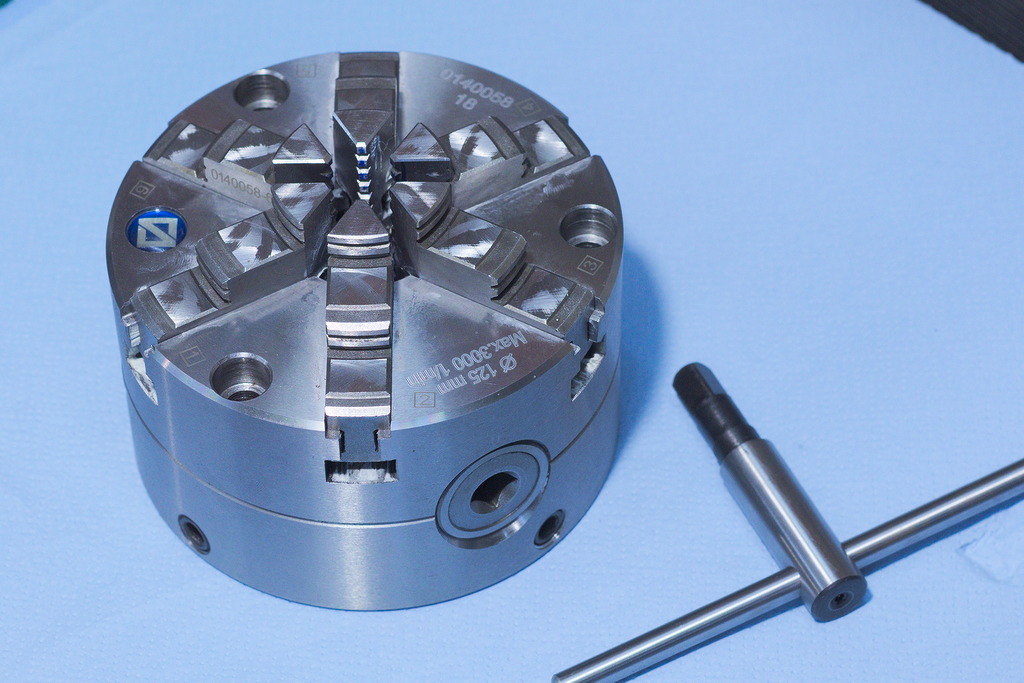

For quite some time I wanted a new chuck for my lathe: A six jaw chuck with fine adjust.

My choice felt on a Zentra branded chuck with a steel body and monoblock jaws.

Why a six jaw? More rigid holding of parts as the space between the jaws is smaller. Especially with soft or thinwalled parts thats a great improvement.

My usual procedure with a new chuck is to take it apart, clean, deburr and lube it properly:

The Zentra chuck was pretty clean to begin with, no grinding grit or things that dont belong in the chuck. But it had a bunch of burrs that I removed and some sharp corners that I rounded and balled over.

The backplate was machined from GG25 cast iron. This is the spindle side:

A good way to testfit the backplate is to take the whole chuck with the part in it off the spindle and test it that way:

Then the part could be flipped over and faced:

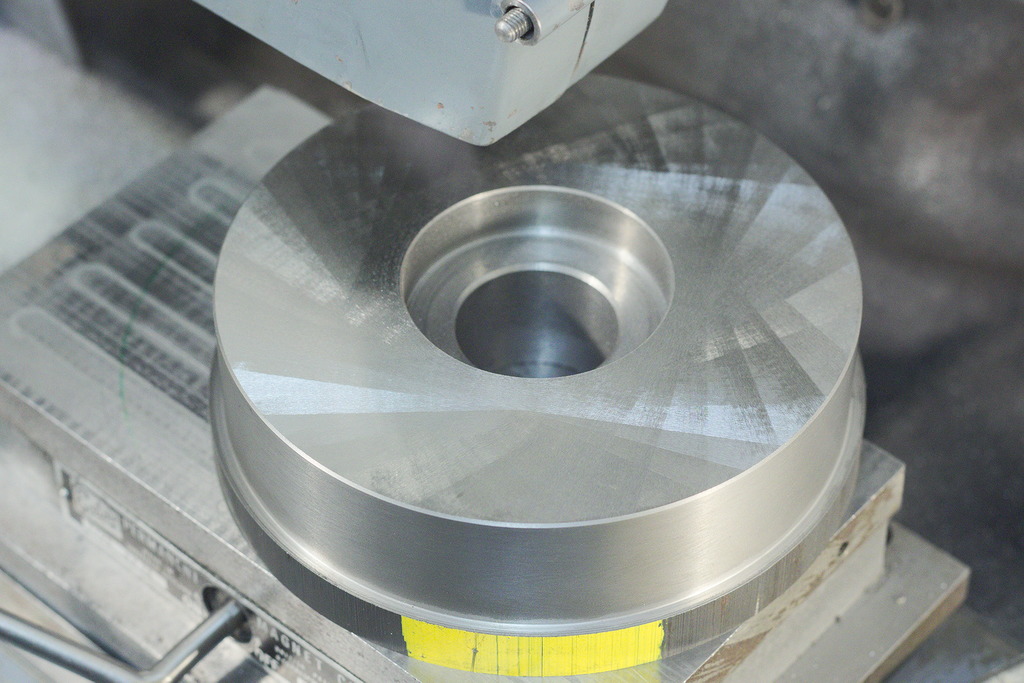

Surfacegrinding both faces of the backplate:

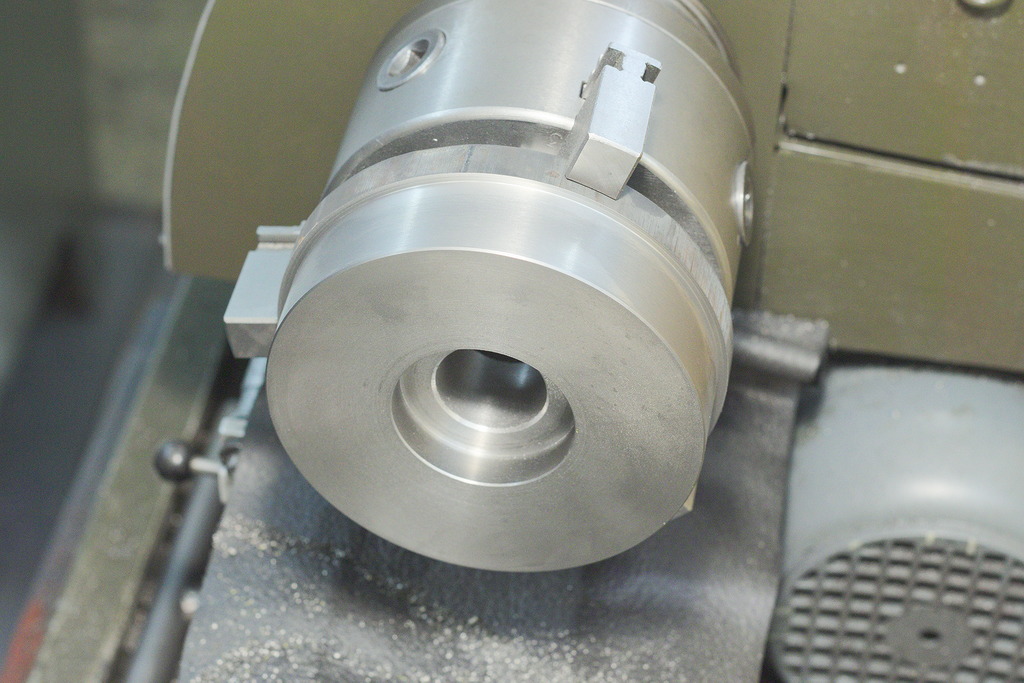

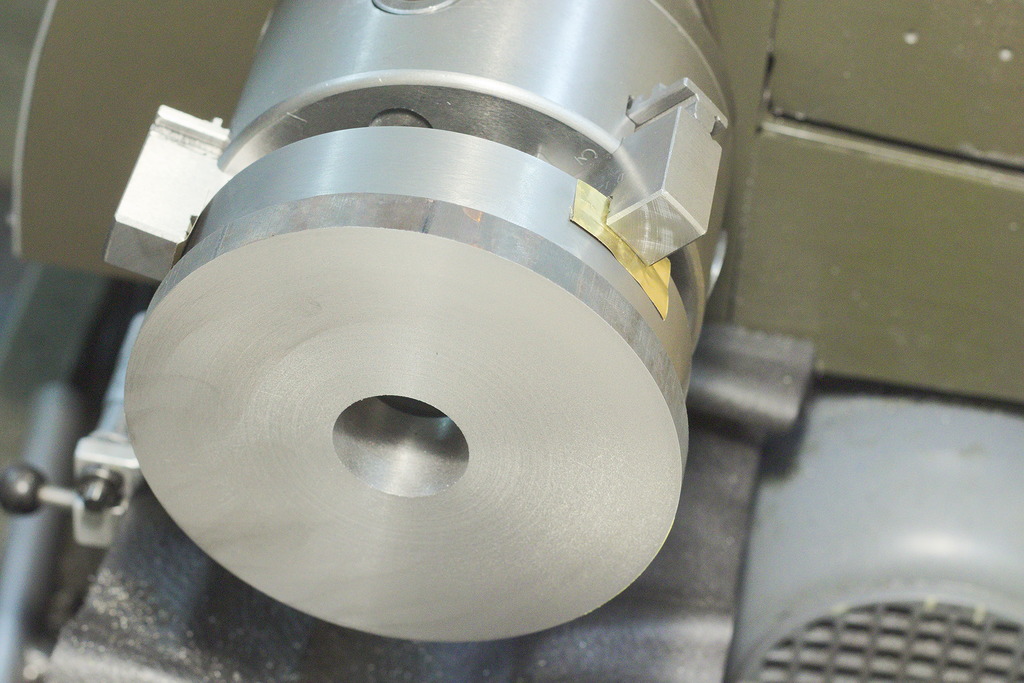

Now the backplate could be mounted to the spindle of the lathe and the interface to the chuck was machined. The register diameter in the center is smaller than the diameter in the chuck, to allow the chuck to be moved with the four fine adjust set screws:

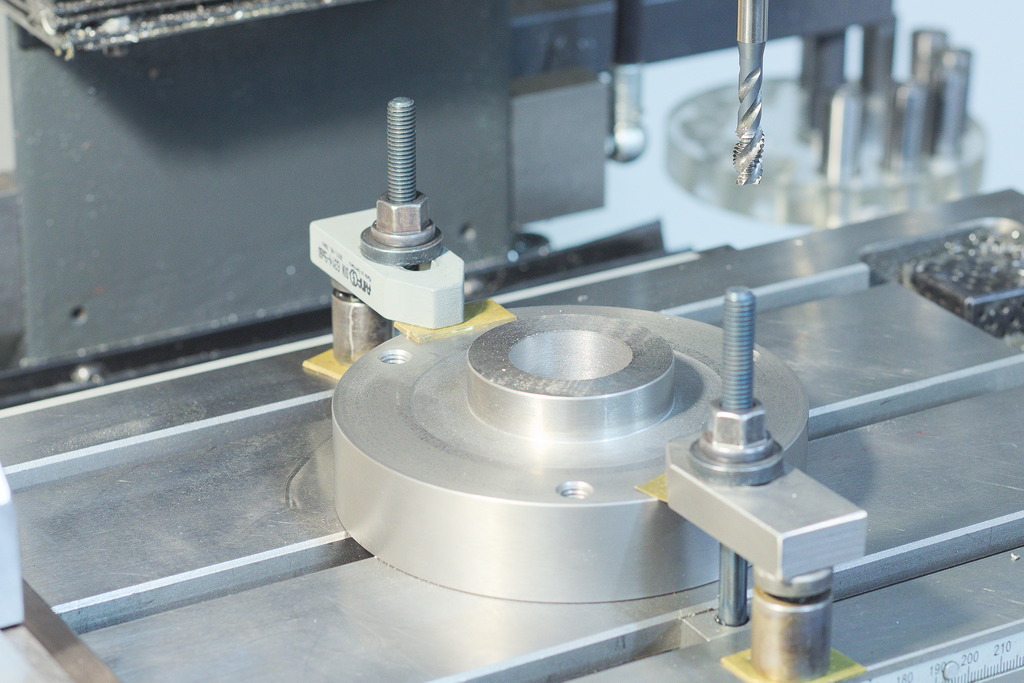

Drilling and tapping the threads to mount the chuck:

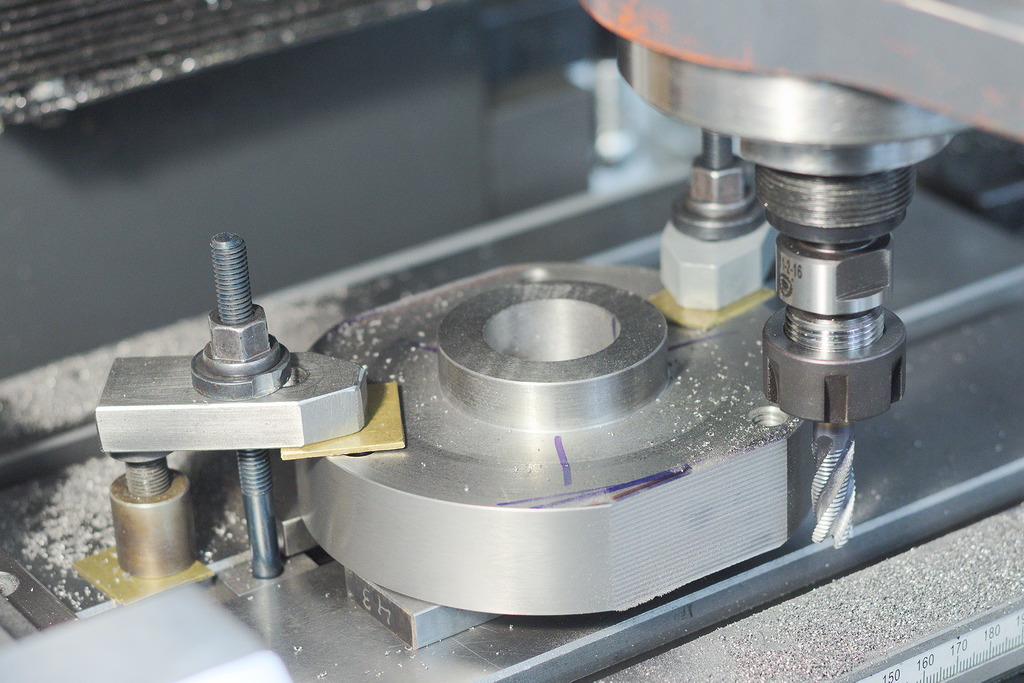

Then I figured to machine two flats on the backplate, so I can hold it in the vise of the mill:

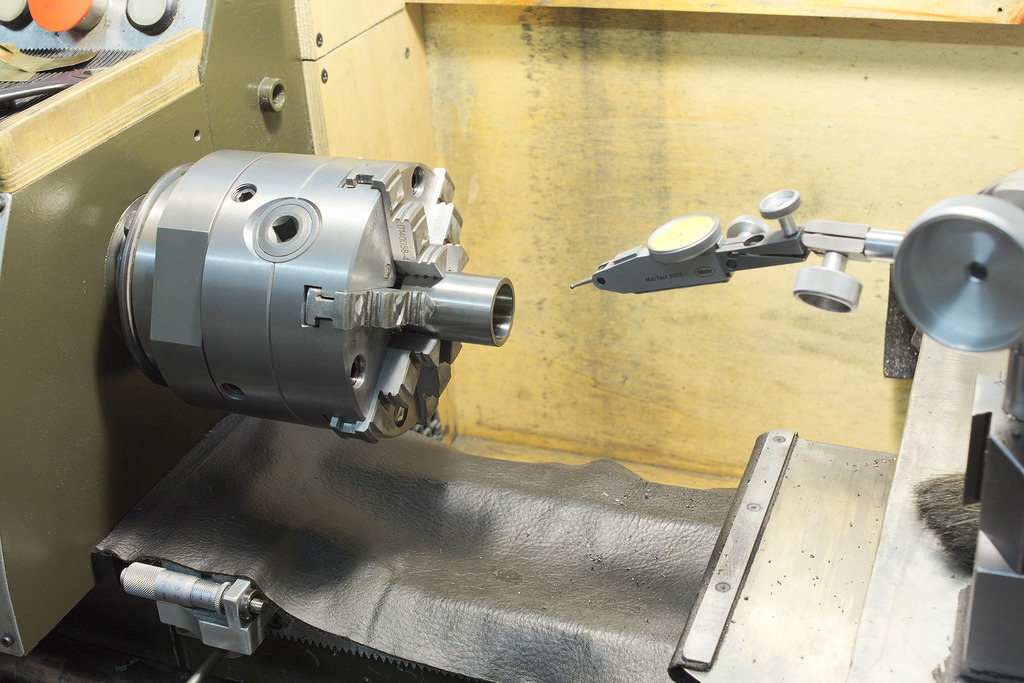

The chuck finally mounted on the lathe:

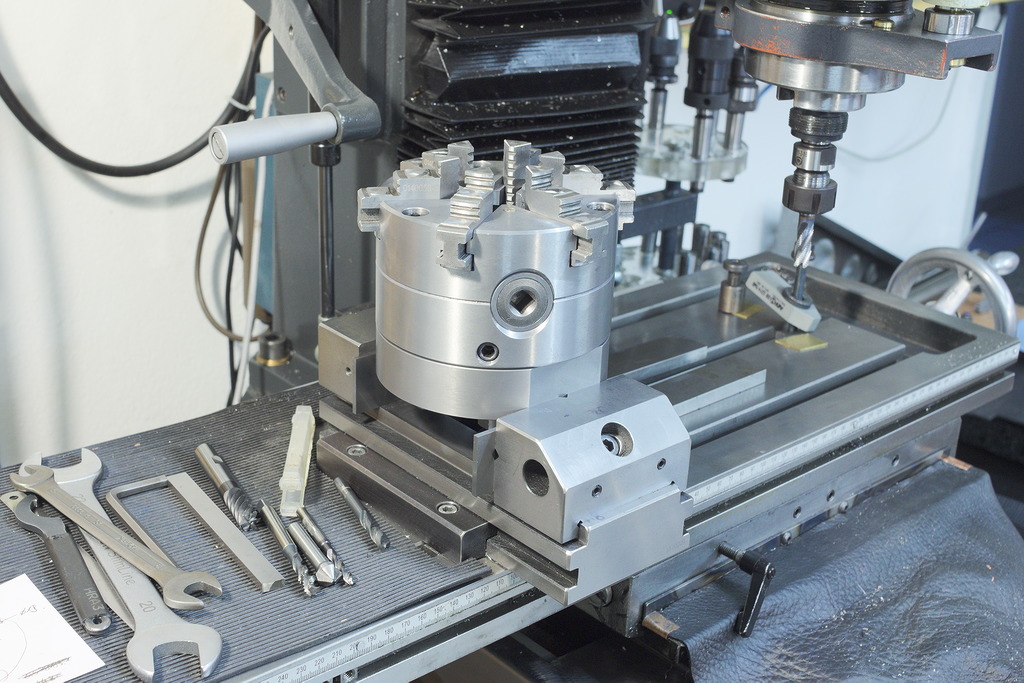

And with the two flats it can go in the vise of the mill:

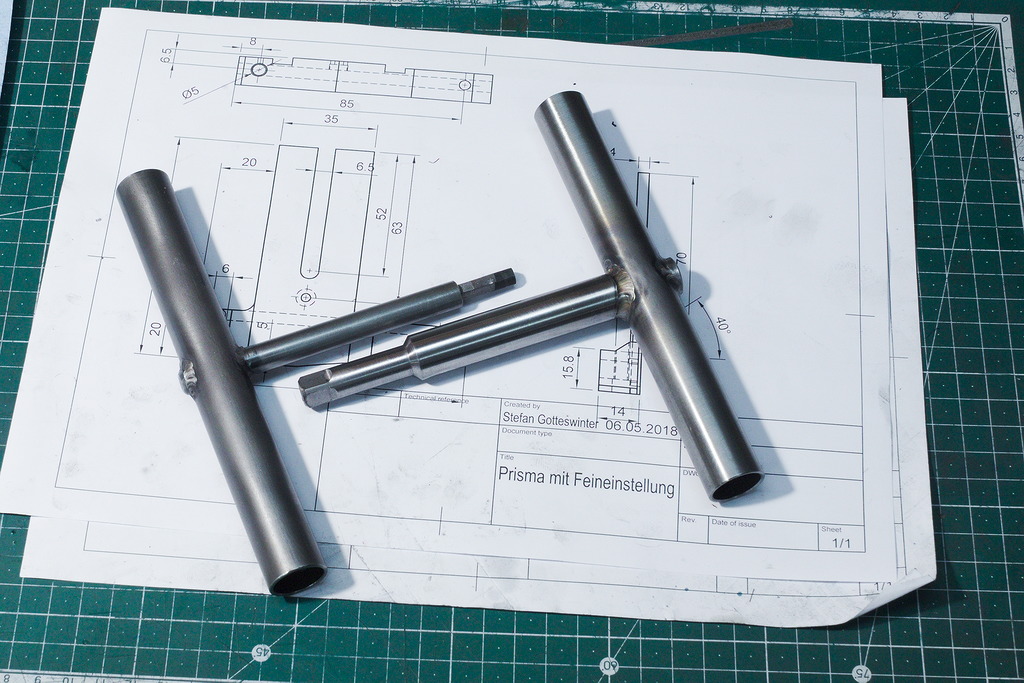

I also made a better chuck key – With a 20mm pipe as the handle. It diggs way less into the palm of the hand when tightening the chuck: