Small projects

Last Update: 01-10-2017

This is a collection of smaller projects that are not worth a dedicated site, but might still be interesting.

Small flycutter - 01-10-2017

Tapmatic board - 16-08-2017

ER11 collet rack - 07-08-2017

G1L Waycover - 13-03-2017

Machine light - 16-01-2017

Bullnose caliper modification - 16-01-2017

Lathe tray - 16-01-2017

5C collet tray - 16-01-2017

Clamping set for the rotary table - 16-01-2017

Clamping bars for a screwless vice - 16-01-2017

Wedges to remove a drill chuck - 16-01-2017

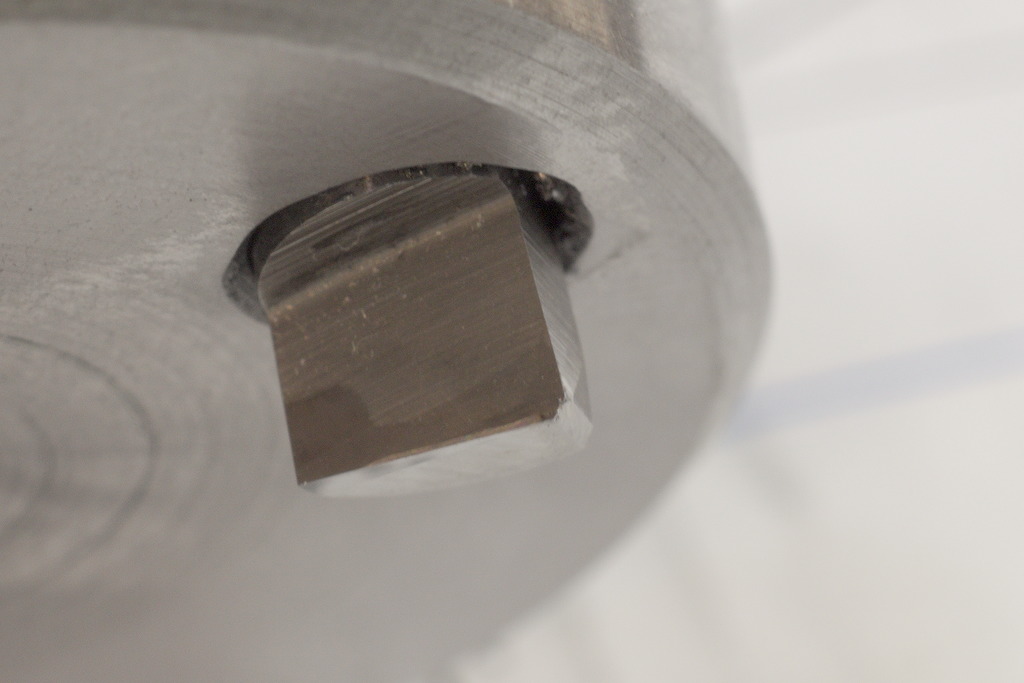

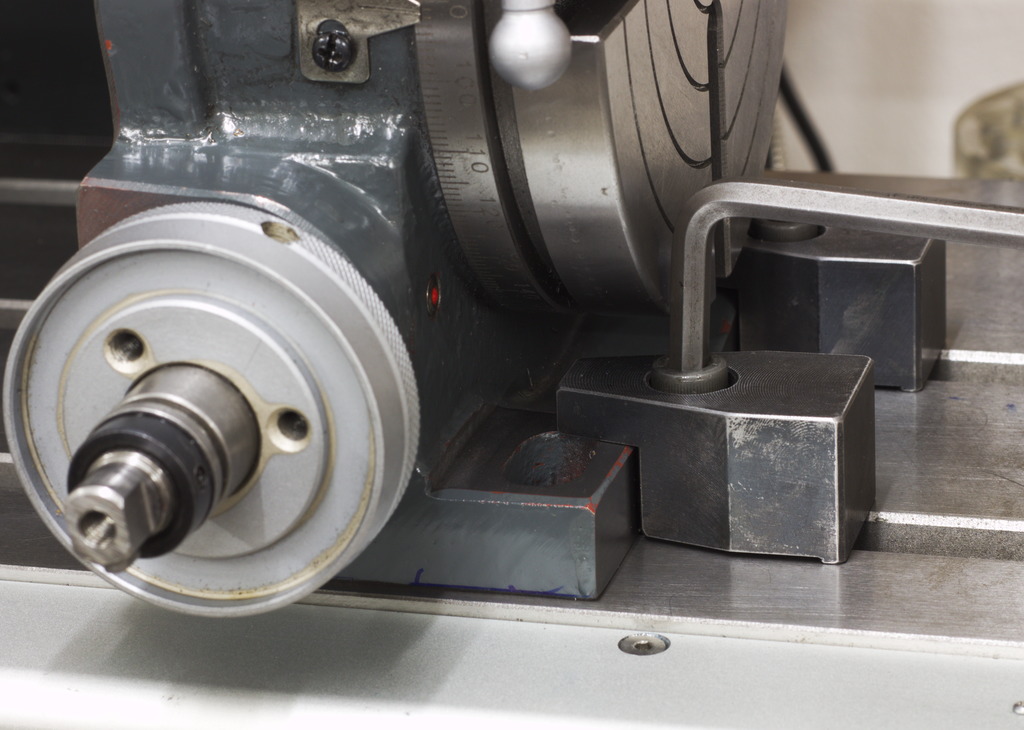

Small flycutter

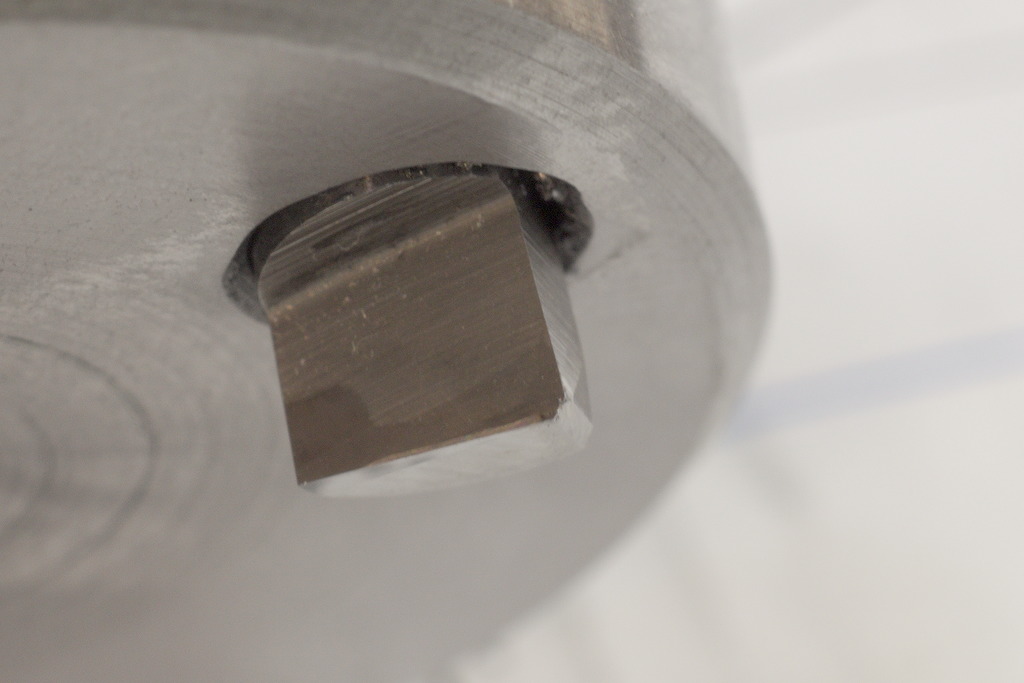

I needed a small flycutter to surface parts out of O2 toolsteel - I had a spare MT2 shank that I turned quite some time ago and it just needed a 6mm bore for a carbide blank and a M5 screw to clamp the cutter. With a good ground cutter, it is an excellent finishing tool, leaving a very good finish that is also precise. With the very sharp cutter, the flycutter actually cuts the metal and does not smear and push the material like certain inserted face mills will do with fine finishing cuts.

Tapmatic board

I got a nice small Tapmatic head that can cut threads from M1,4-M7 with all the accessories. I machined a storage board to hold everything in place on the Isel Cnc router out of a piece of ash:

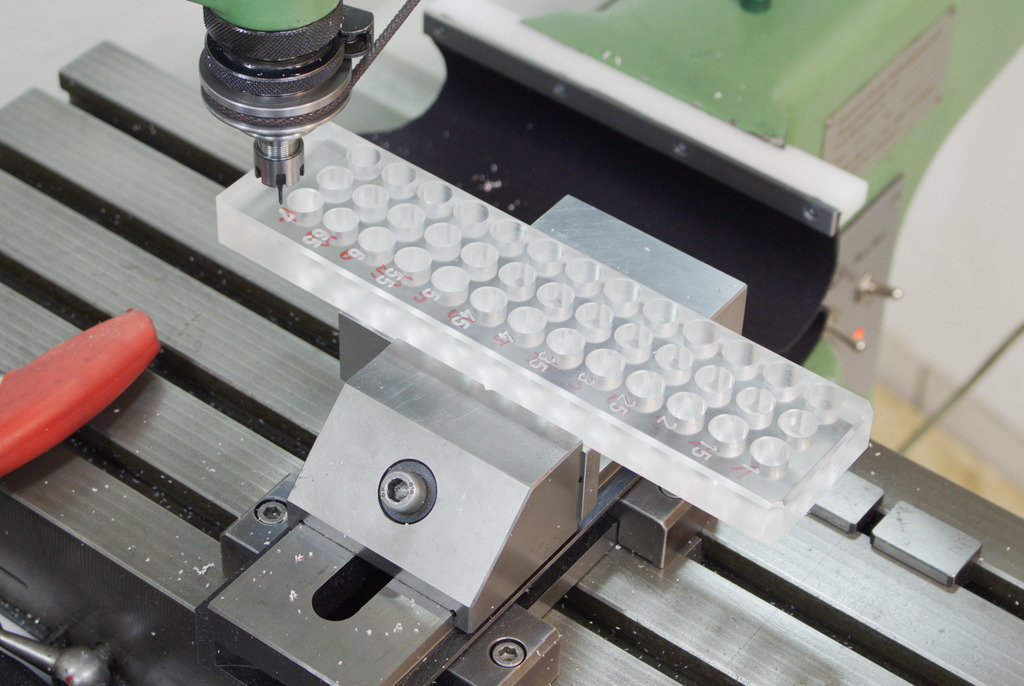

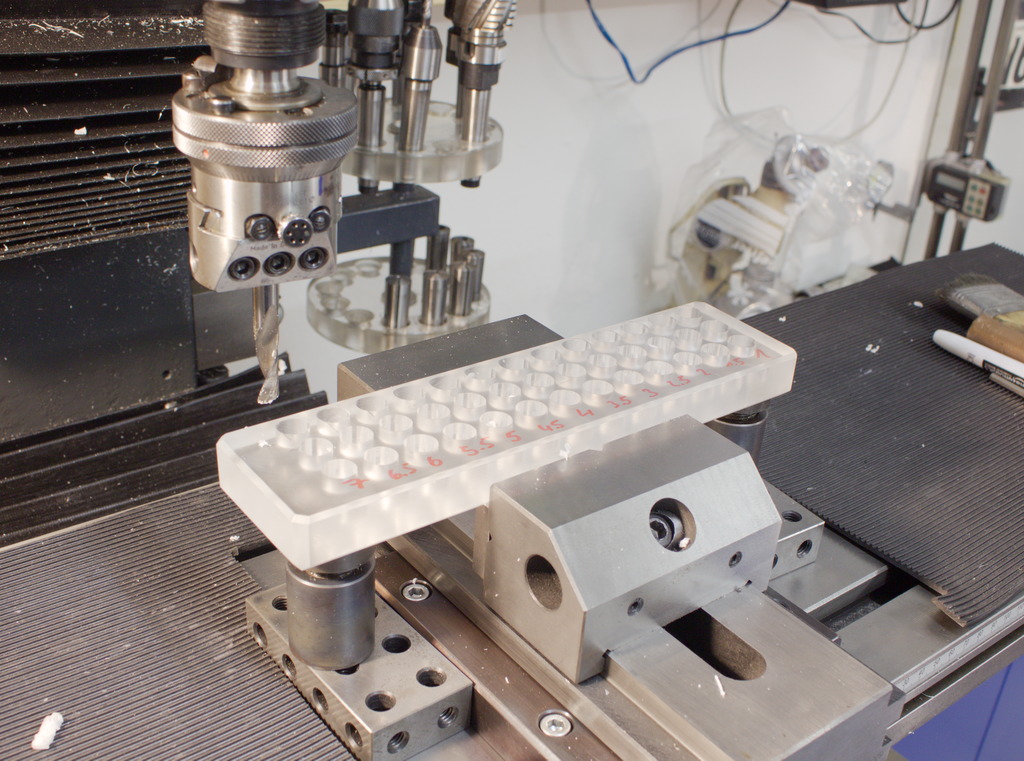

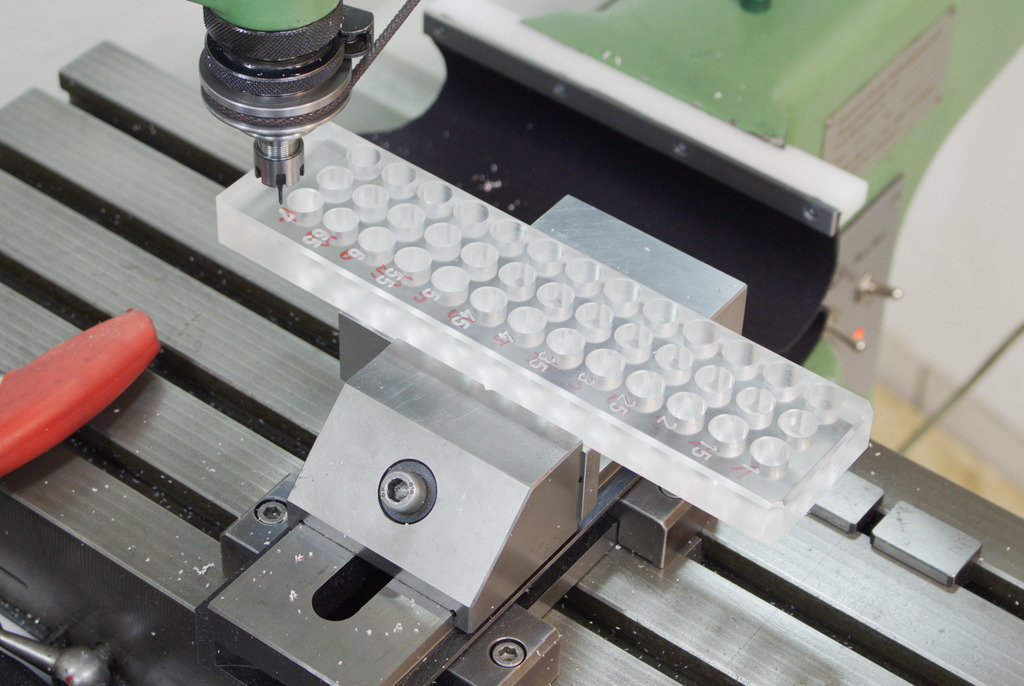

ER11 collet rack

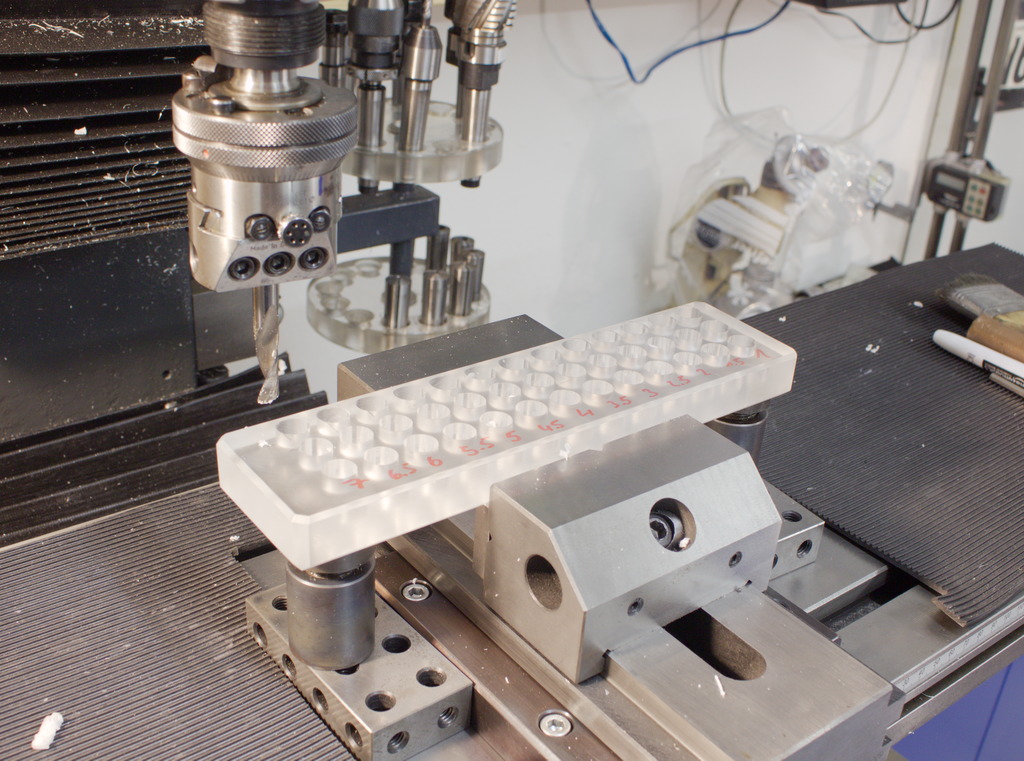

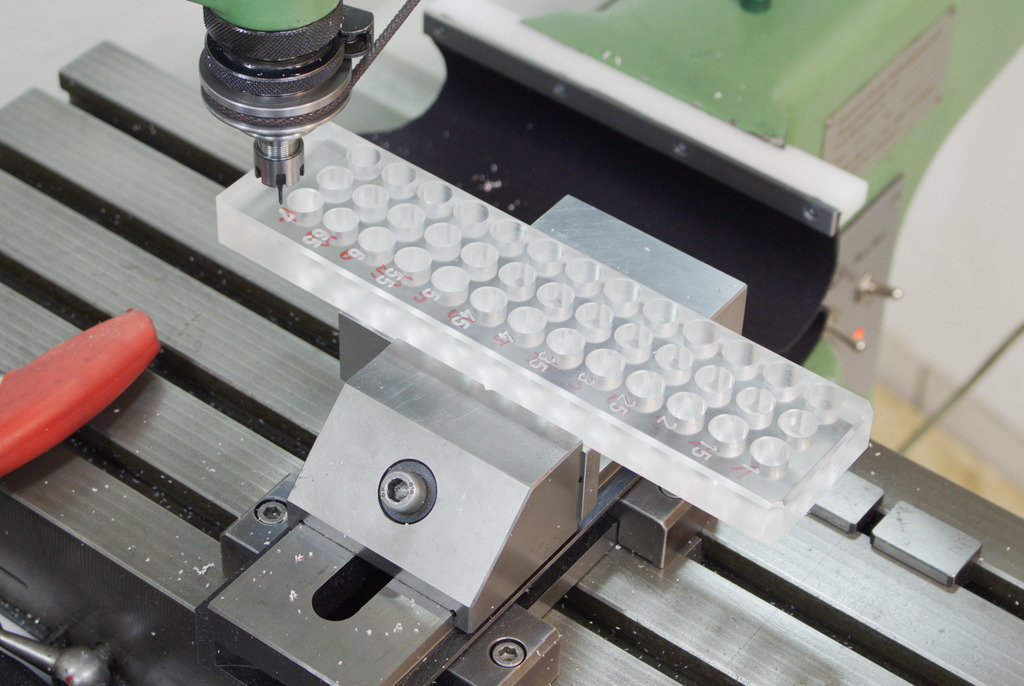

Since I had thee full ER11 collet sets I needed some way to store and organize them – So I took a scrap piece of 20mm Acrylic and bored a bunch of holes into it – As I didn’t have a fitting drill bit, I used a single flute endmill in the Wohlhaupter boring head to bore directly into the plastic, without predrilling, which works very well in soft materials:

Engraving the numbers using the G1L:

The finished ER11 collet rack – Also to be seen, my complete assortment of collets. I have three complete sets ER11 that I use a lot for drills and small endmills, and one set each ER16 and ER25, but also a few ER8:

Deckel G1L way cover

On my Deckel G1L engraving machine there is nothing protecting the Y- and Z-slideways against chips. While the Y-direction has at least wipers, the Z-direction has nothing, and fine chips (especialy when engraving steel) are always a danger of scratchingand wearing the slideways.

The cover I designed uses 2mm neoprene (covered with fabric on both sides) and two brackets to hold it to the column and to the cross slide of the machine. The bracket on the column is machined to slide snug over the dovetail ways, the other bracket has three magnets pressed into it and its flat up against the cross slide:

The front of the Y-Way is protected by a second cover, it is held with magnets against the wipercover. The neoprene stock is clamped with a strip of coldrolled steel against the polycarbonate part:

The neoprene/fabric material is good for cold chips and oil/cooleant, but it melts with hot chips - So it is not very good for way covers on milling machines and lathes.

Machine light

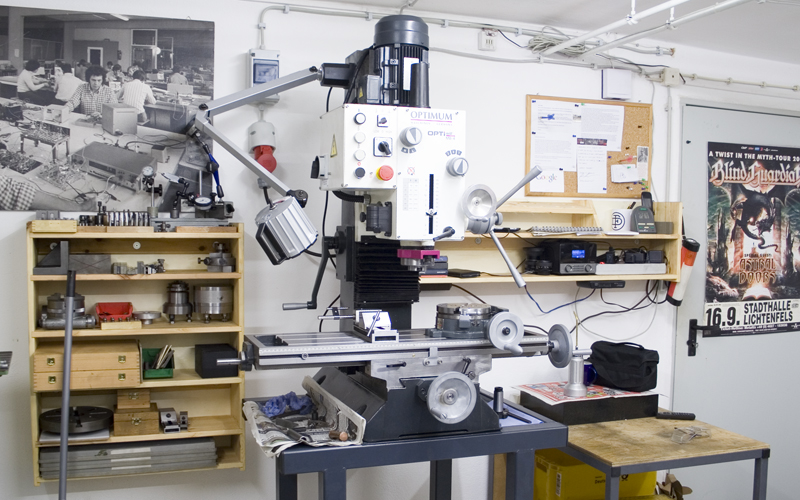

When I bought my milling machine, I ordered a machine light with it. 55W halogen bulb, water proof.

I soon realized that I don't like this lamp very much, it does not hold its position very good, it gets very hot and it is hard to adjust its position:

I replaced it with a Ikea Tertial desk lamp and a 21W Led bulb. The lamp holds it position very good and is easy to adjust and the Led bulb does not only consume less power than the halogen lamp I had before, it also puts out more light and does not get hot:

I have the same lamp on my lathe and on the workbench. They are cheap and very rugged.

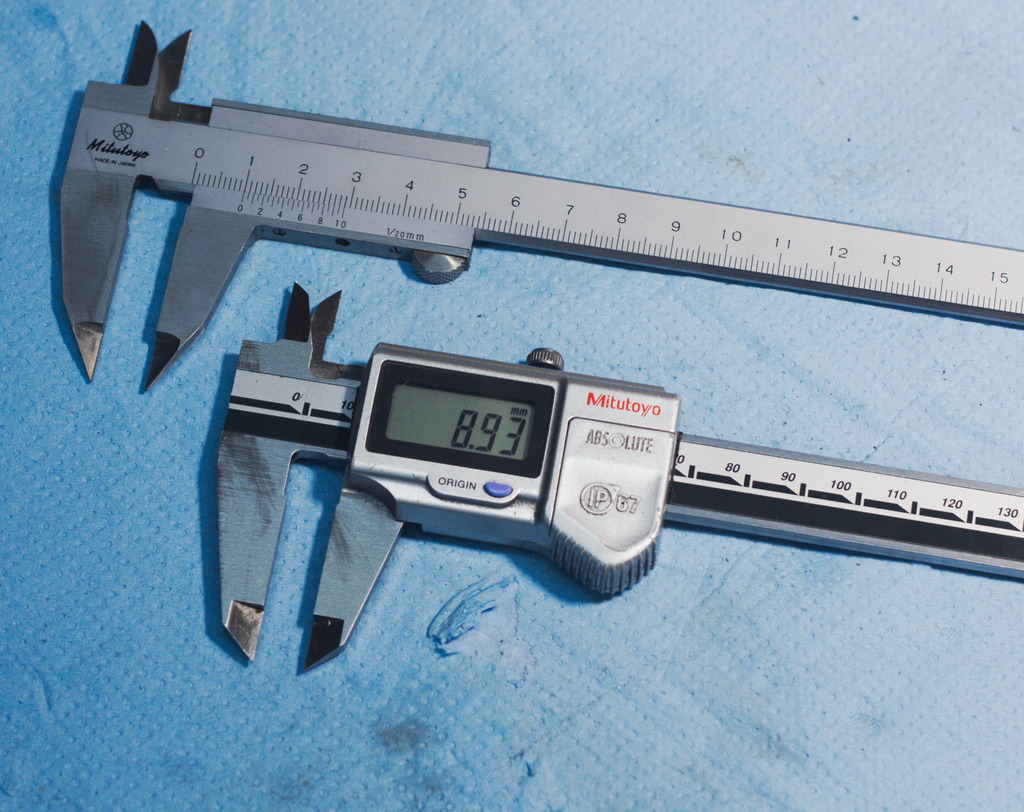

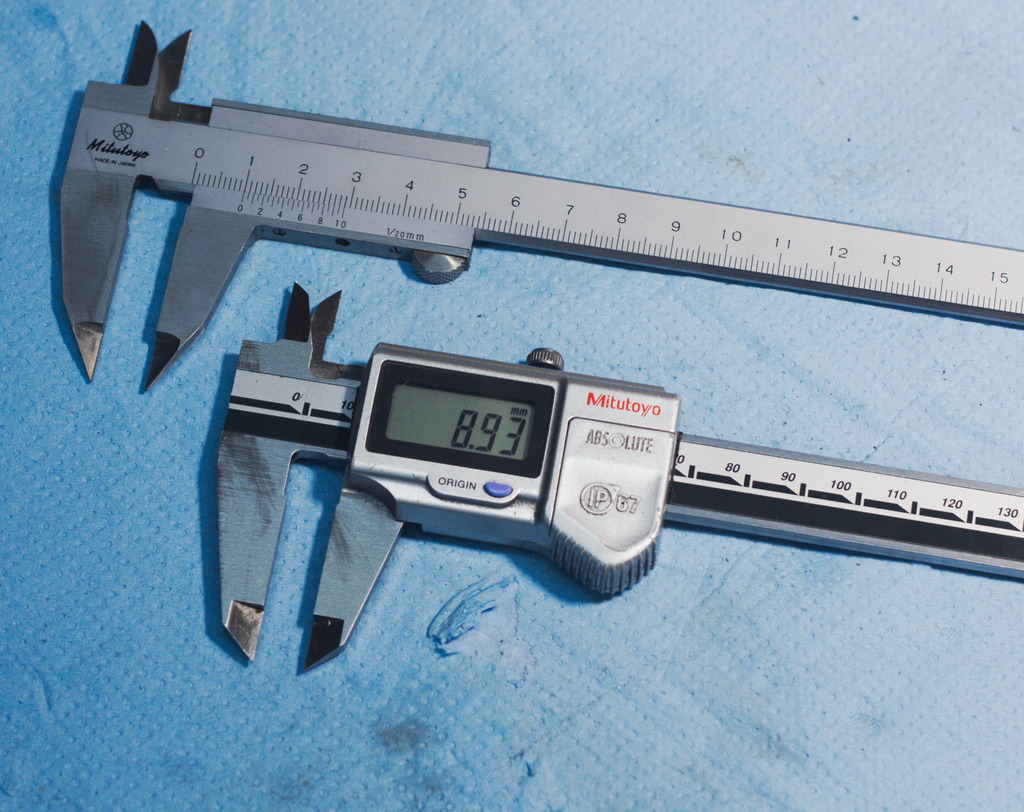

Bullnose caliper modification

Lathe tray

A tray that bolts to the top of the headstock and holds all the tools that you use during a job - For example measuring tools and the chuck key. I also added a piece of 4mm sheet metal where the magnetic indicator stands can be stored.

5C collet tray

A drawer insert to hold my 5C collets:

I did not have a 33mm drill bit so I used the router, a 6mm single flute endmill, a 10mm bushing and a template to mill out all the holes. This also gives a much cleaner hole than using a forstner bit:

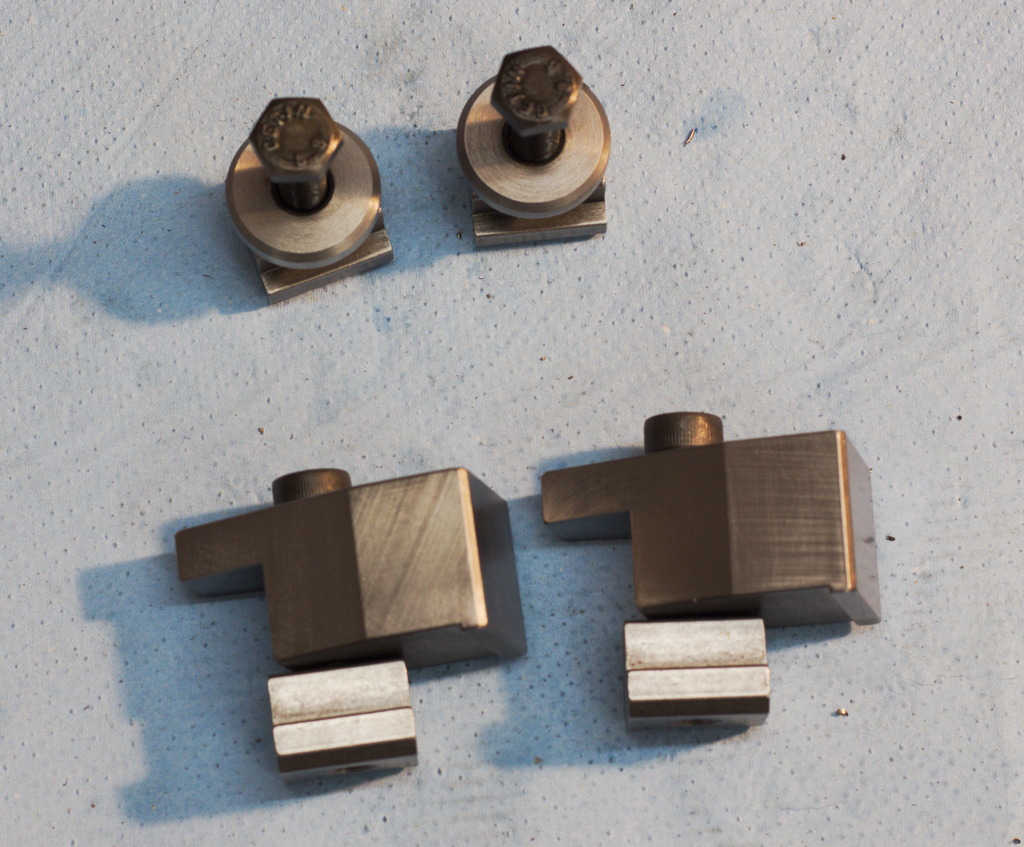

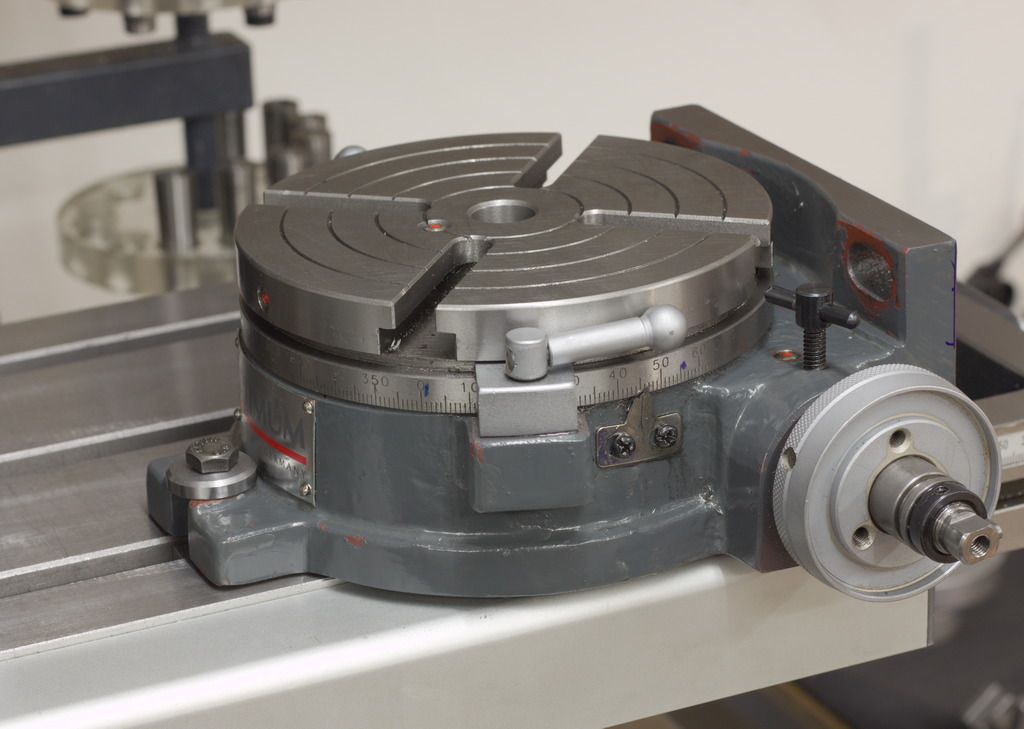

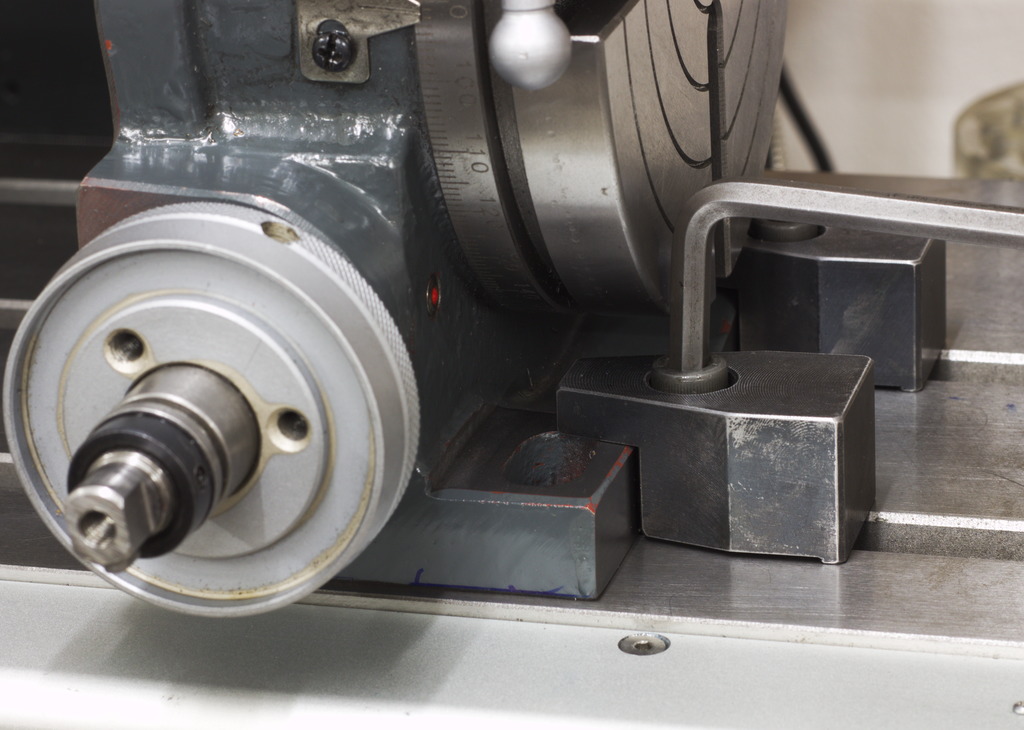

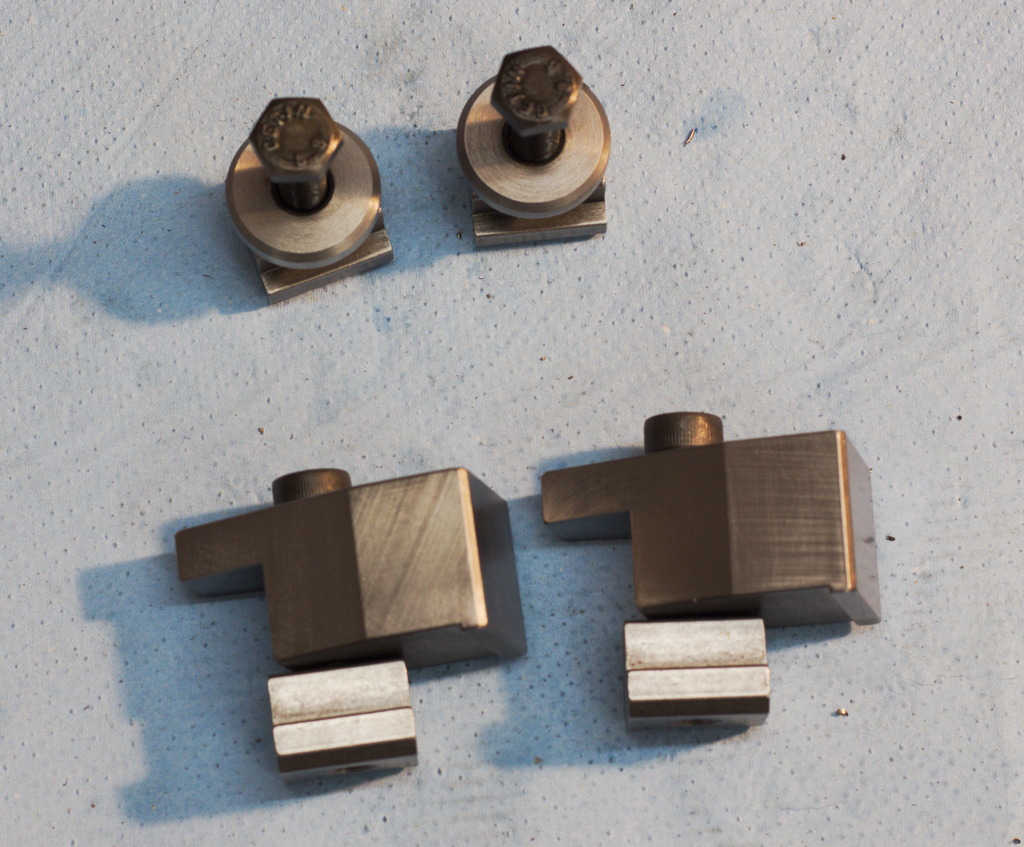

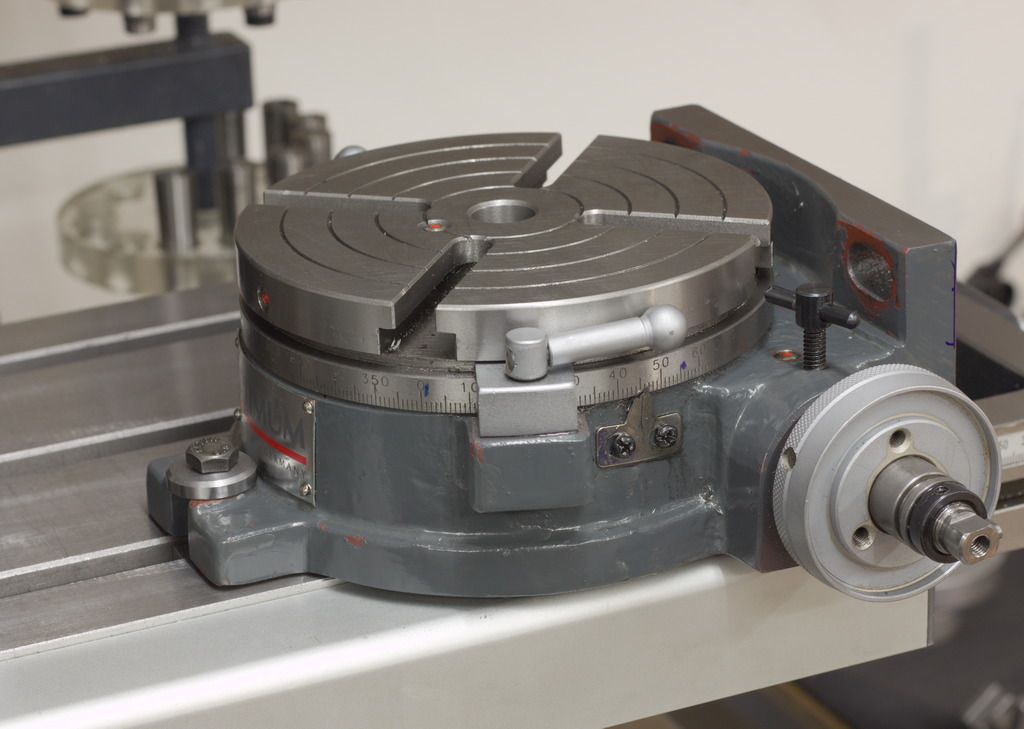

Clamping set for the rotary table

I made a dedicated set of clamps to hold my rotary table in horizontal and vertical position:

Heavy washers, screws and t-nuts to hold it in horizontal position:

Clamps, screws and t-nuts to hold it in vertical position:

The washers and the clamps are machined out of carbon steel and hardened to 40..45Hrc.

All the parts can stay together and there is no need to search for the right parts each time I have to setup the rotary table.

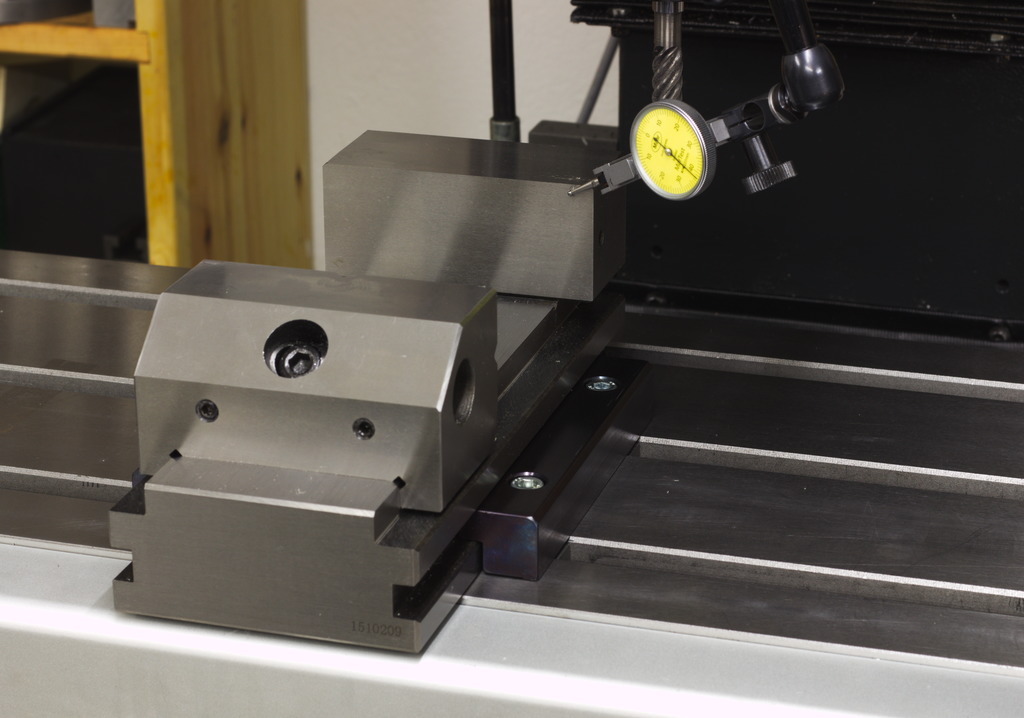

Clamping bars for a screwless vice

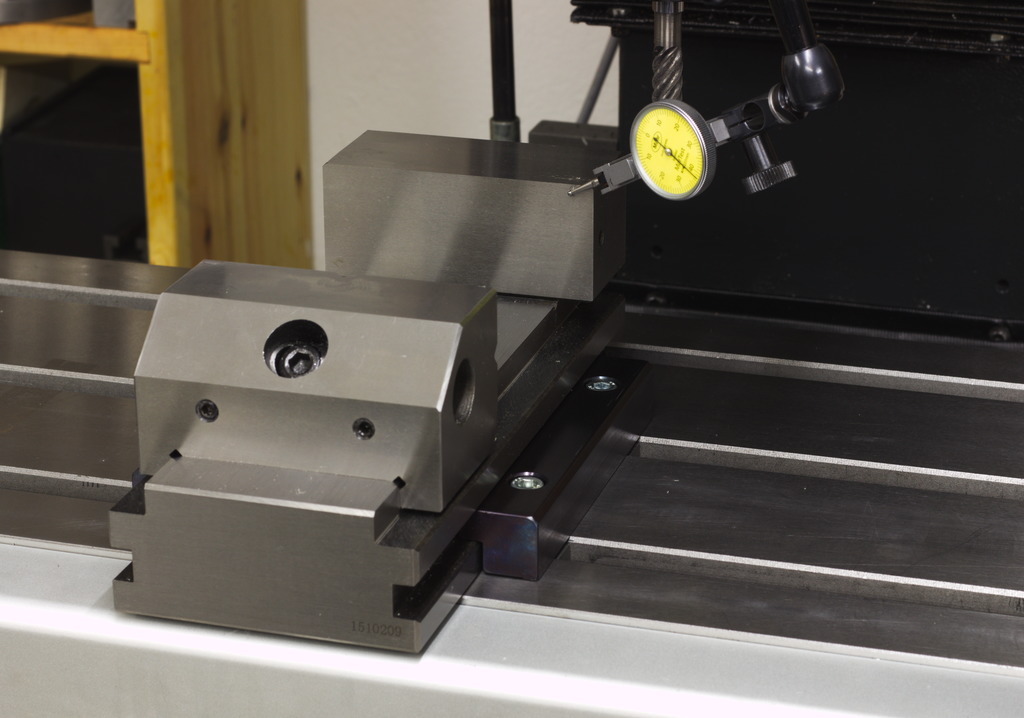

A pair of clamping bars to hold my 90mm wide grinding vice on the table of the milling machine. Machined from mild steel and heat blued (300°C in the oven):

Wedges to remove a drill chuck

To seperate a drill chuck from its arbor, I made those split wedges:

Machining them is straight forward, I starded out with a longer piece of round stock, clamped at an angle on the milling machine, then it got surfaced and the slot cut into it. Last step was to part it off on the lathe. Do that two times and you end up with a matching pair of wedges.

I you want to use them frequently, it is a good idea to hardem them.