To me, the 3d Printer is less a machine to make customer parts, but its a great support machine, to create covers, brackets, holders, etc. to be used in my own shop.

As I was not sure how much I am going to use the printer, I went very cheap and got myself a Creality Ender 2 - For a couple of reasons:

In my mind, a 3d printer is only worth the investment if you are able to do your own 3d models, otherwise you are limited to print parts that other people shared online, for example on Thingiverse.

The Cad I use is Fusion360 from Autodesk, thats also what I use for all my other designs and to do the programming for my cnc router. The Cad you want to use needs to have an option to export the 3d Model as an STL file.

The STL model gets processed with an external slicer software, which can be described as a Cam package for 3d printers.

There are two free and one commercial options out (And a bunch more, but those are the common ones):

Most of the parts I print are either PLA (very rigid, but also brittle, very low melting point), PETG (less rigid, more durable) or TPU (A elastic material, almost indestructible, very chemical resistant)

The filaments I used so far:

Different 3d printed parts:

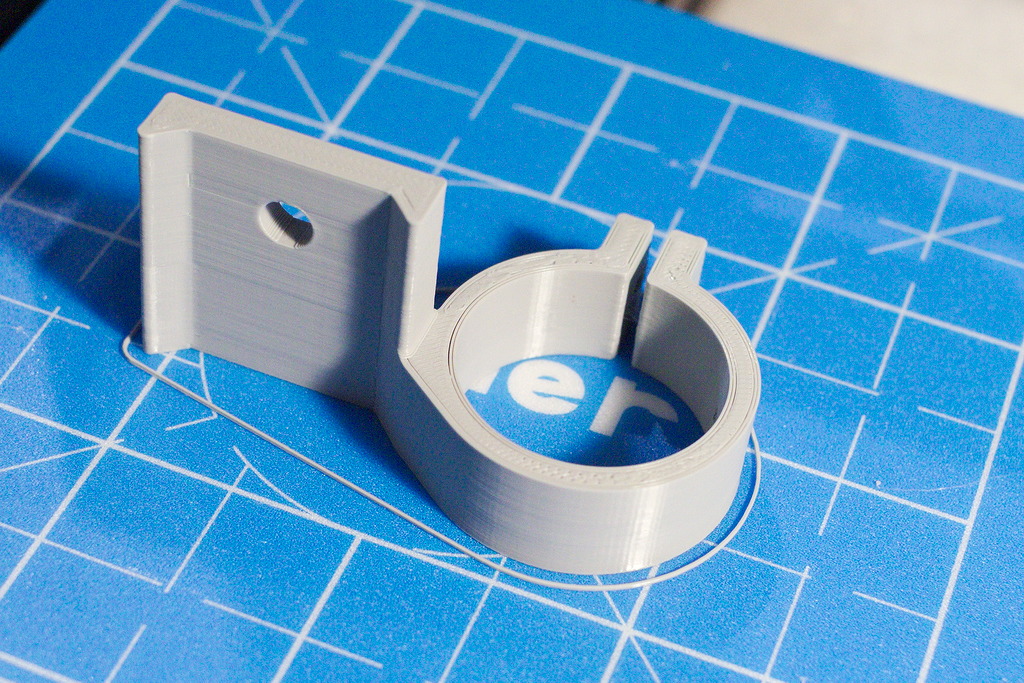

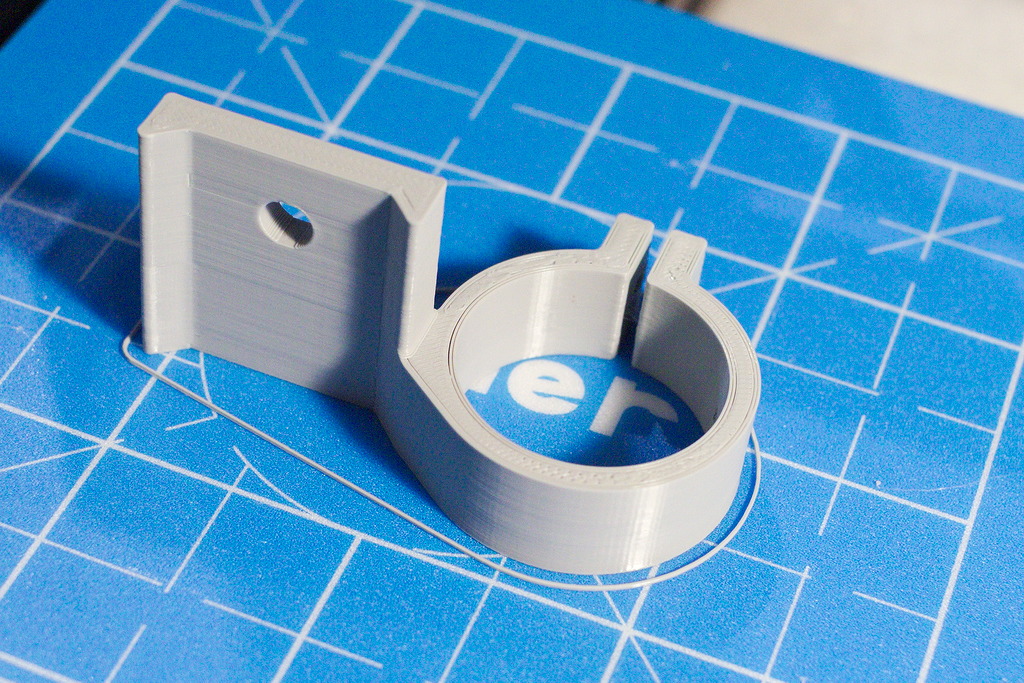

For my audio recording I use a Zoom H1 recorder that runs on AA batteries. I wanted to run the recorder with a USB powerbank, so I can recharge it with a normal phonecharger - To hold the powerbank to the recorder, I designed this bracket and printed it in PLA:

This is a storage bracket for my Biax diegrinder, it clamps to the air-oiler thats needed to run the grinder and allow to keep the grinder off the bench:

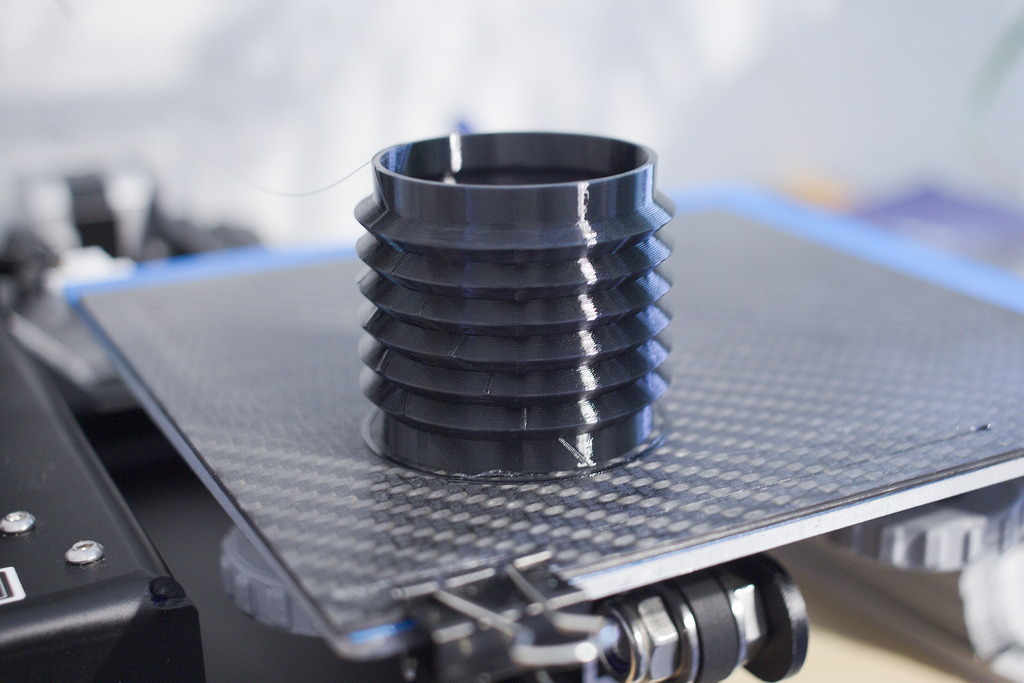

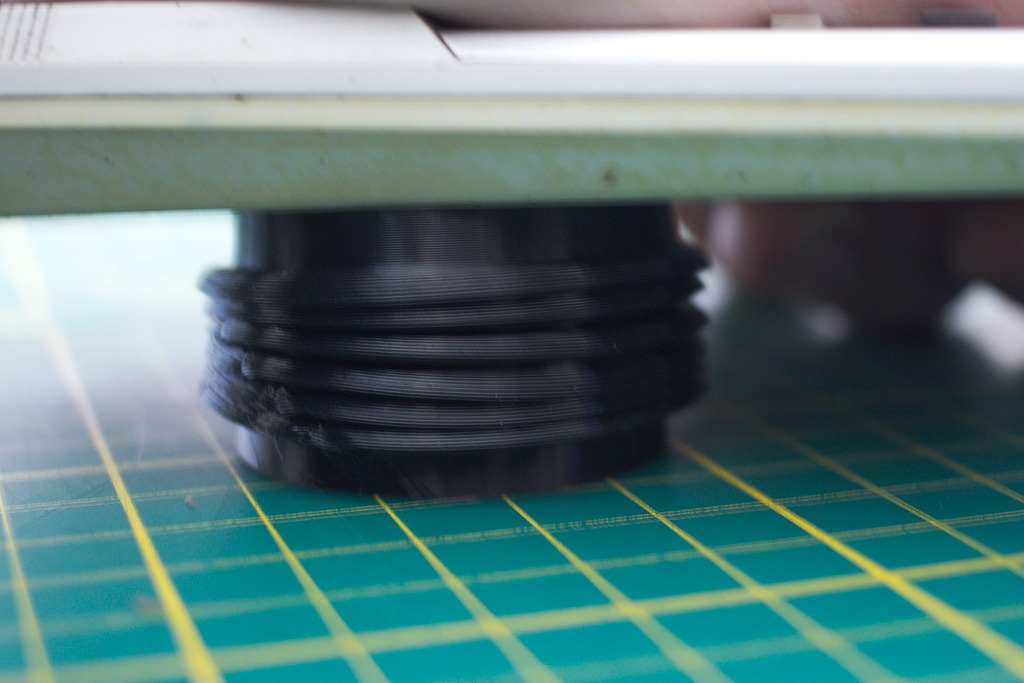

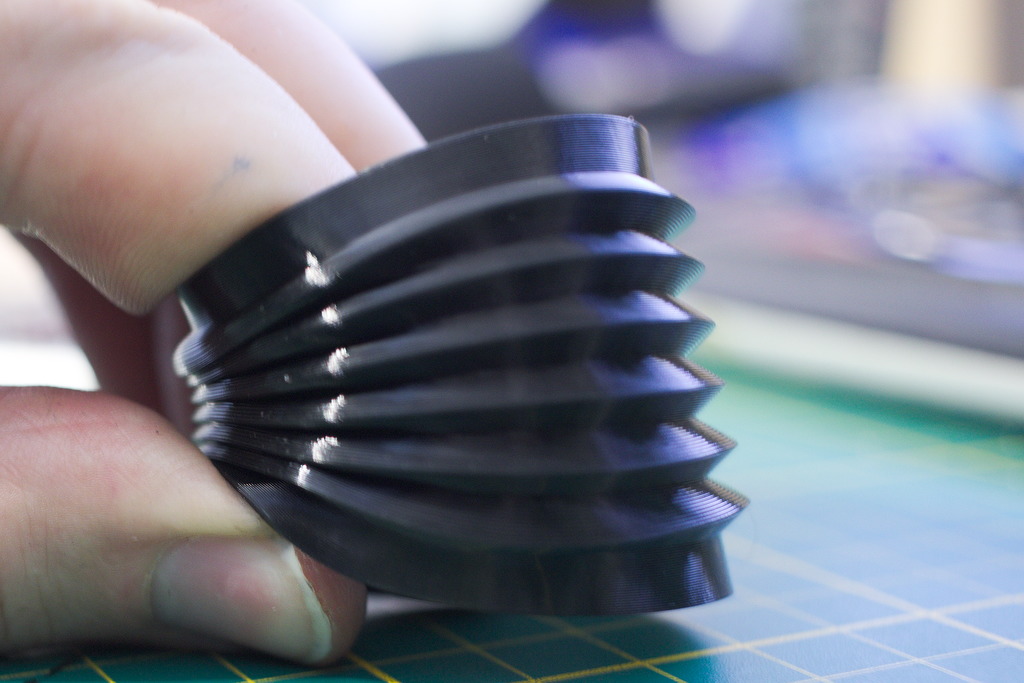

Testpart, to see if flexible bellows could be printed with TPU filament - It works:

A vacuum adapter for my chamfer mill:

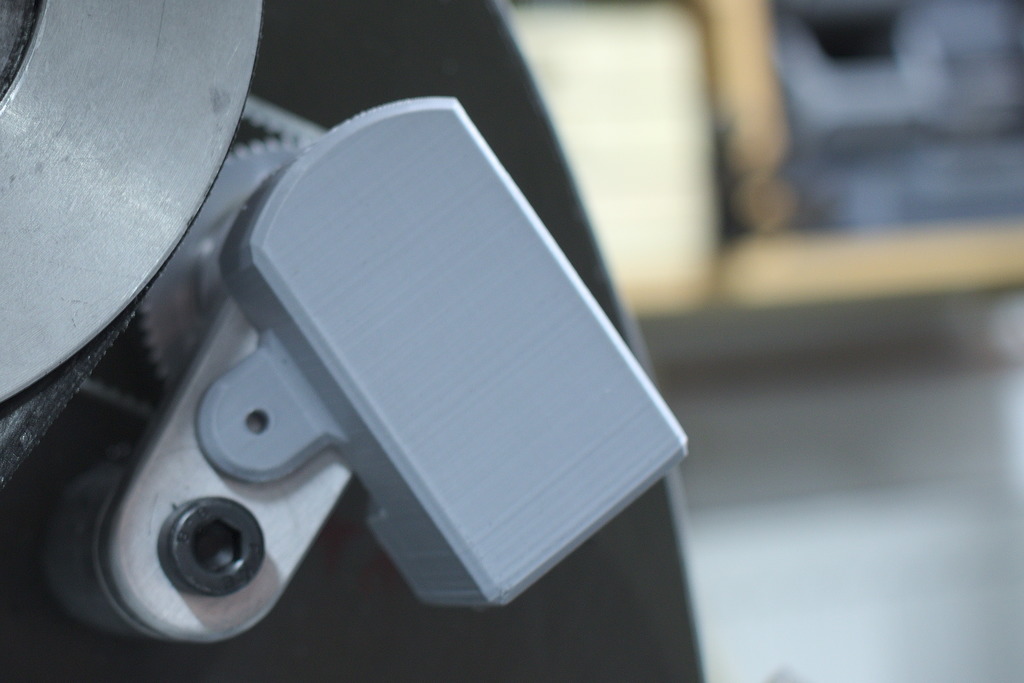

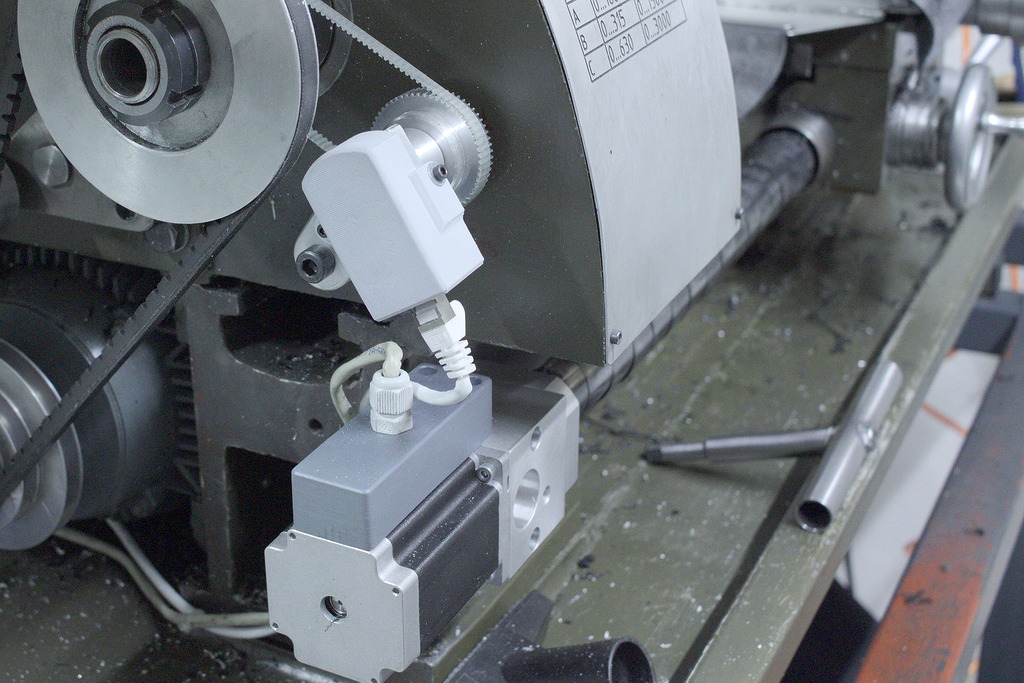

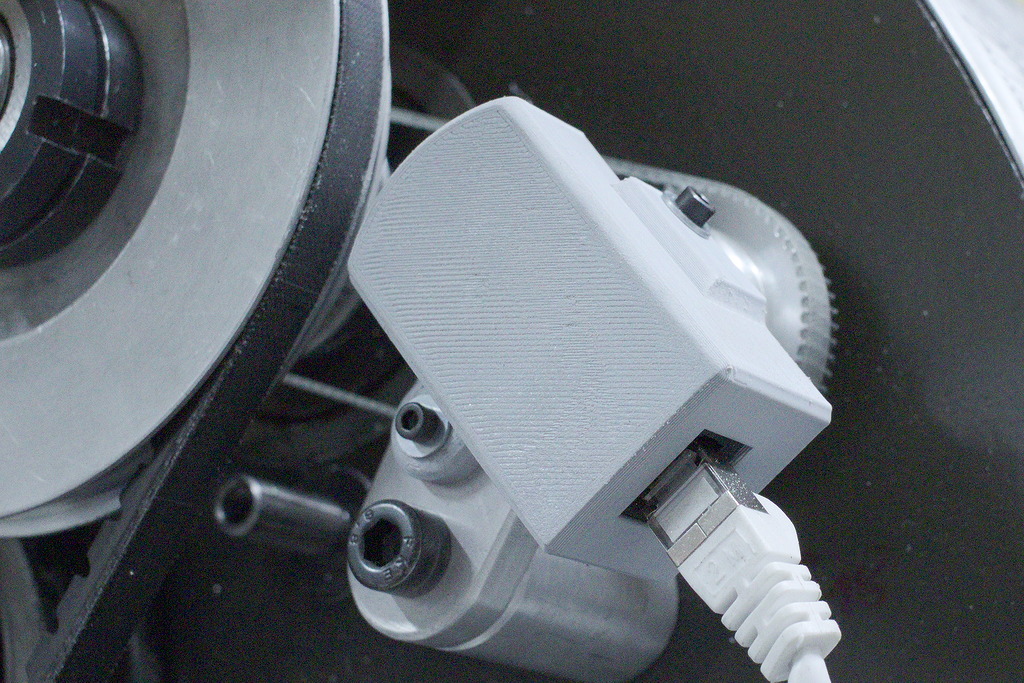

Protective cover for the rotary encoder on my lathe:

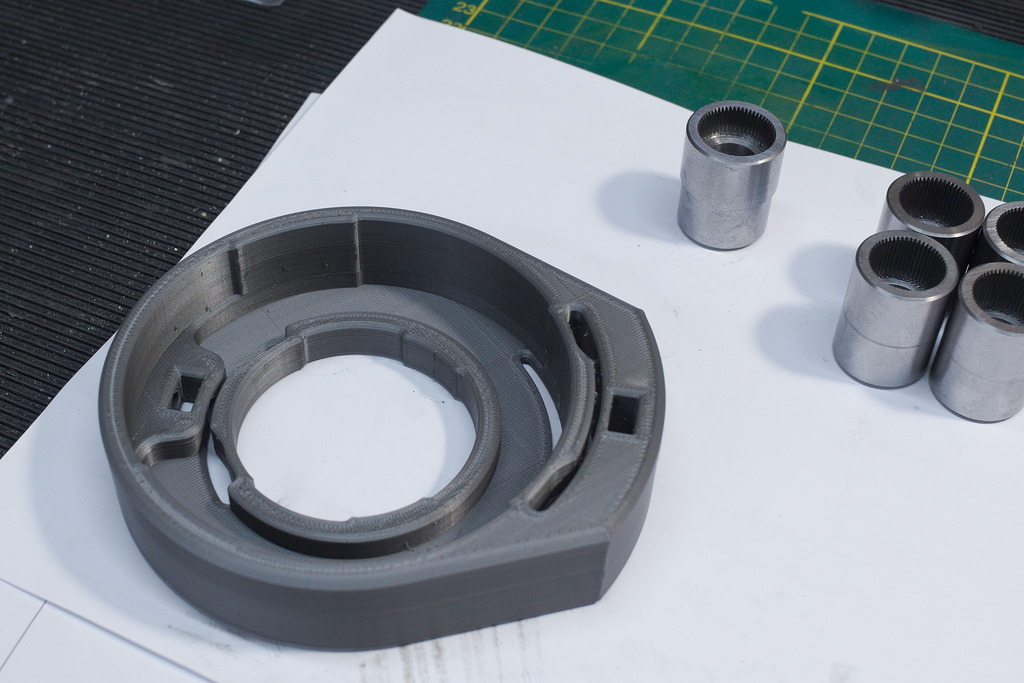

Clamp, that locks onto the quill and the spindle nose of my mill, to lock it from rotating to allow broaching/slotting.