Care was taken to match the taper very precisely and keep a very fine surfacefinish on it.

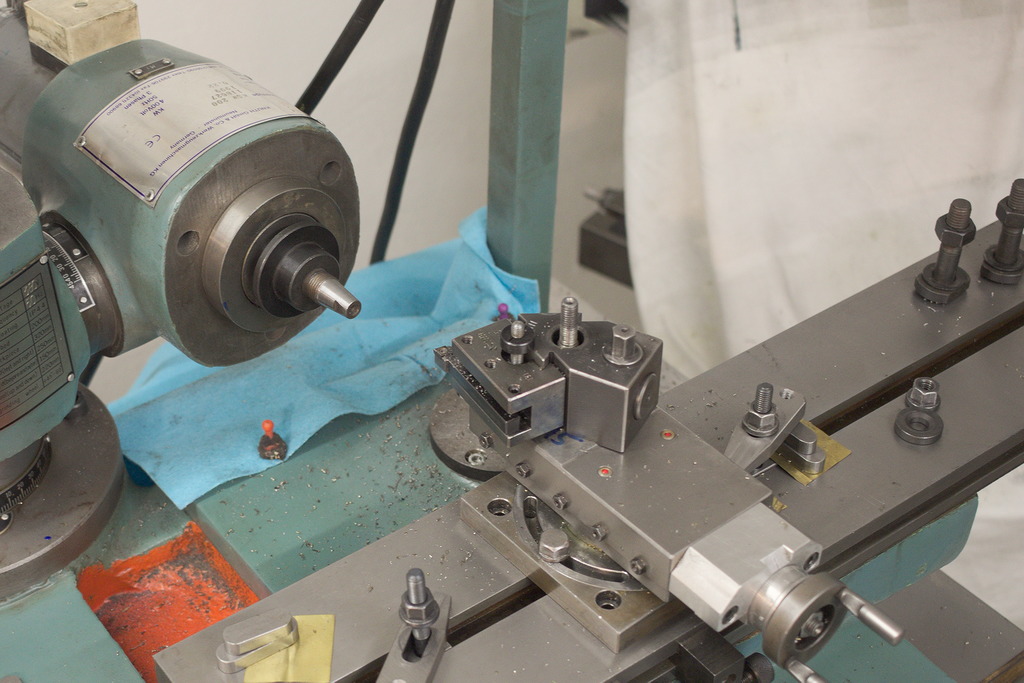

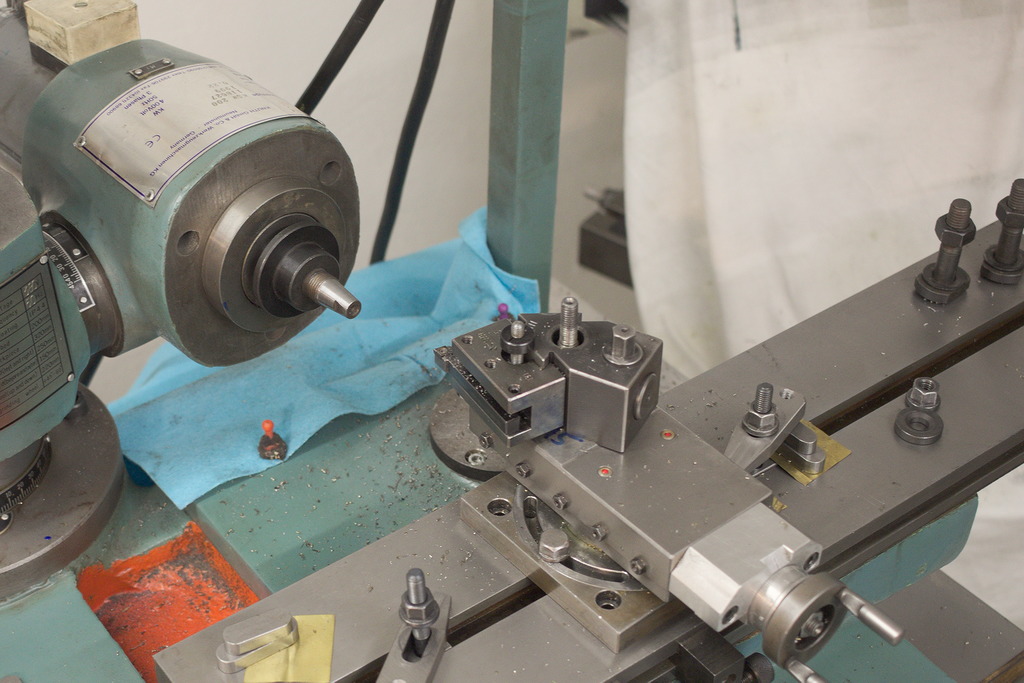

I took the compound slide of my lathe, clamped it to the table of the grinder and turned down the end of the spindle to the same taper as my other two grinders.

Care was taken to match the taper very precisely and keep a very fine surfacefinish on it.

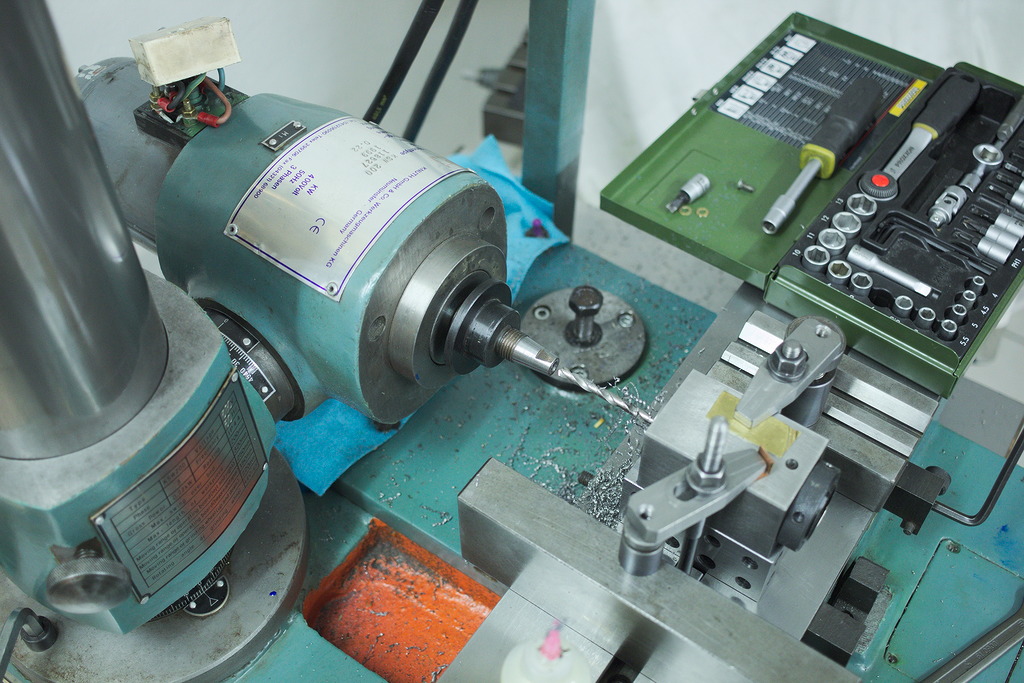

The end of the spindle needed to be drilled and tapped for a M6 thread which is needed to hold the wheelhubs in place.

The drill is held in a 5C collet block.