I trepanned the majority of the material out with a DCMT turning tool by plunging straight in.

Flanges where machined out of 15mm PVC that slip over the column with a very close fit – To those flanges the bellows are clamped with large steel hoseclamps.

I trepanned the majority of the material out with a DCMT turning tool by plunging straight in.

Another problem with the vertical column was the very insufficient clamp of the axis. From factory it was just a large thumbscrew that presses against the column – Not a very desirable solution.

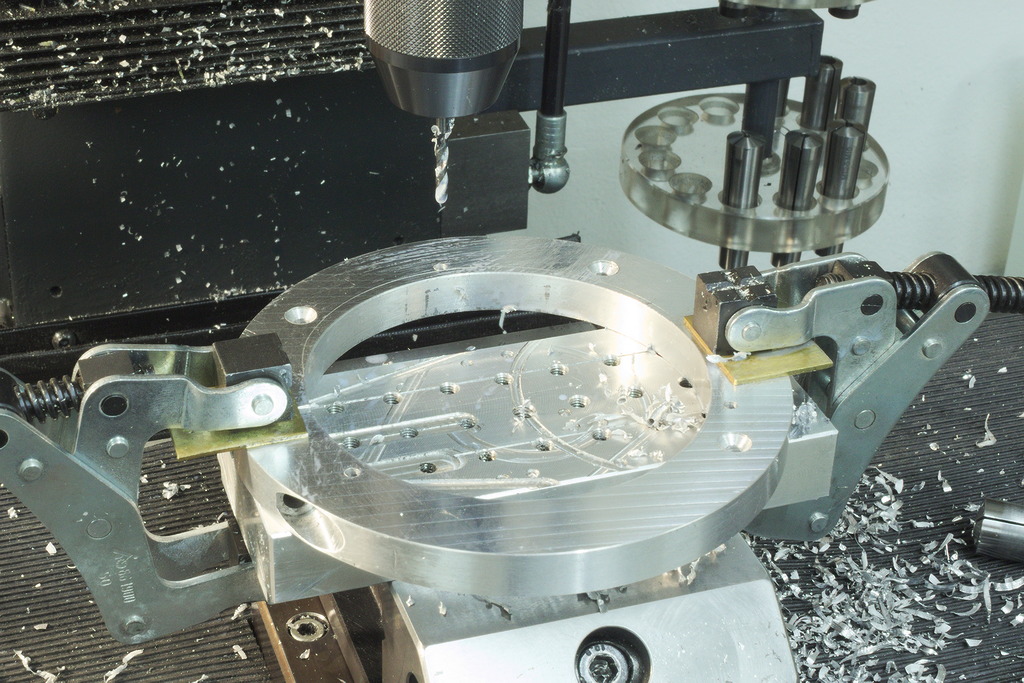

I machined a slitted clamping ring out of aluminium, that got screwed to the top of the vertical slide – By clamping this ring, the complete vertical slide is held very secure in place.

In the last picture you can also see one of the flanges to mount the bellows in place.

The bellows and clamp in place. The clamping ring can be seen on the upper end of the vertical slide.