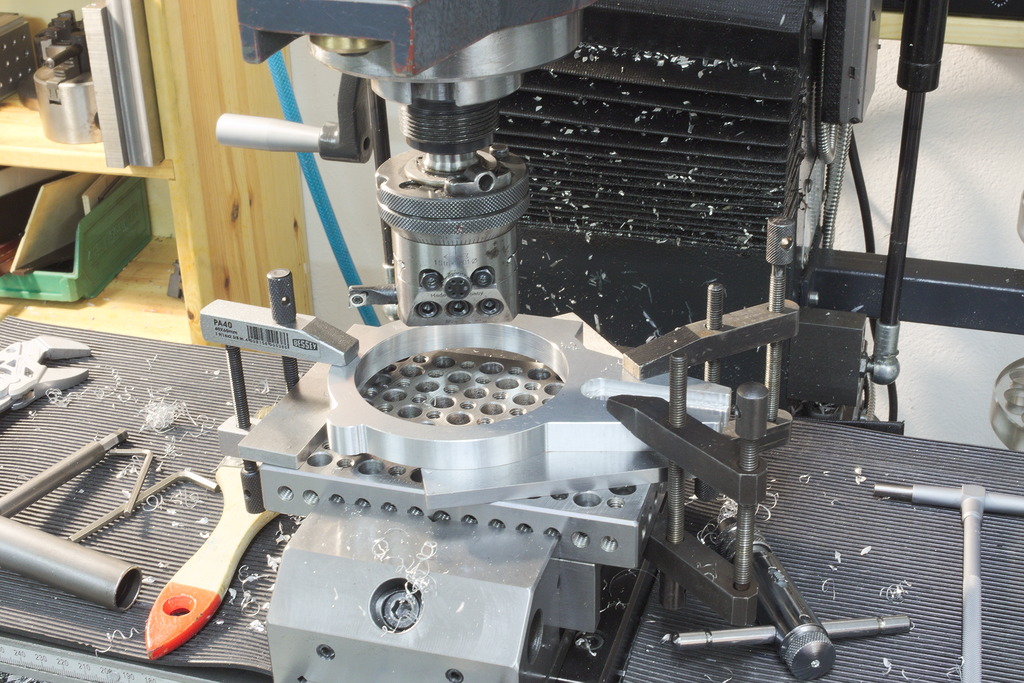

I started by cutting an aluminium bracket on the cnc router – But left the centerbore slightly small, it got bored to final diameter on the manual mill – The router can not do precise bores by interpolating.

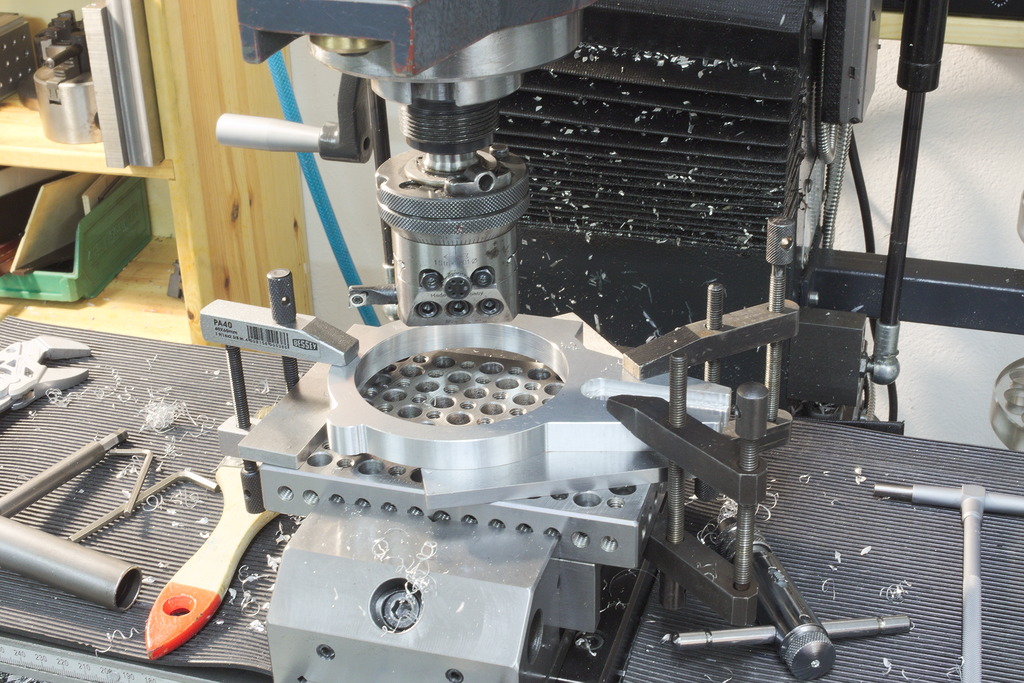

Drilling and tapping a hole for clamping the bracket to the spindle. I clamped the part against a large steel plate to give it more rigidity during drilling and slitting:

That’s the bracket in place on the spindle, already with the overarm support in place that will hold the actuall guard.

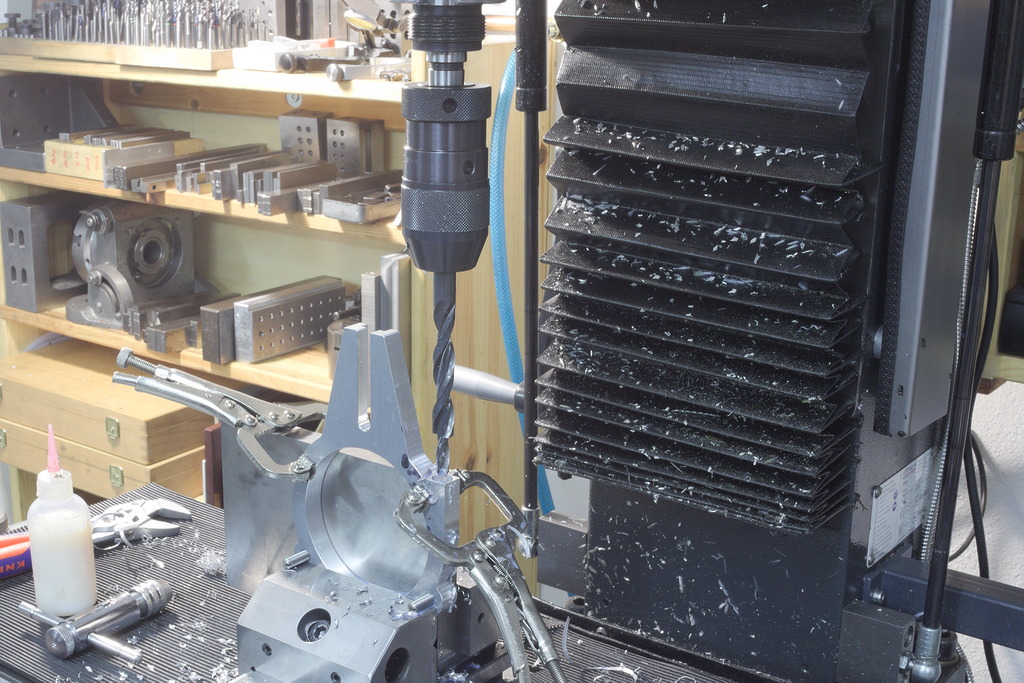

Facing a piece of large diameter pipe to final length:

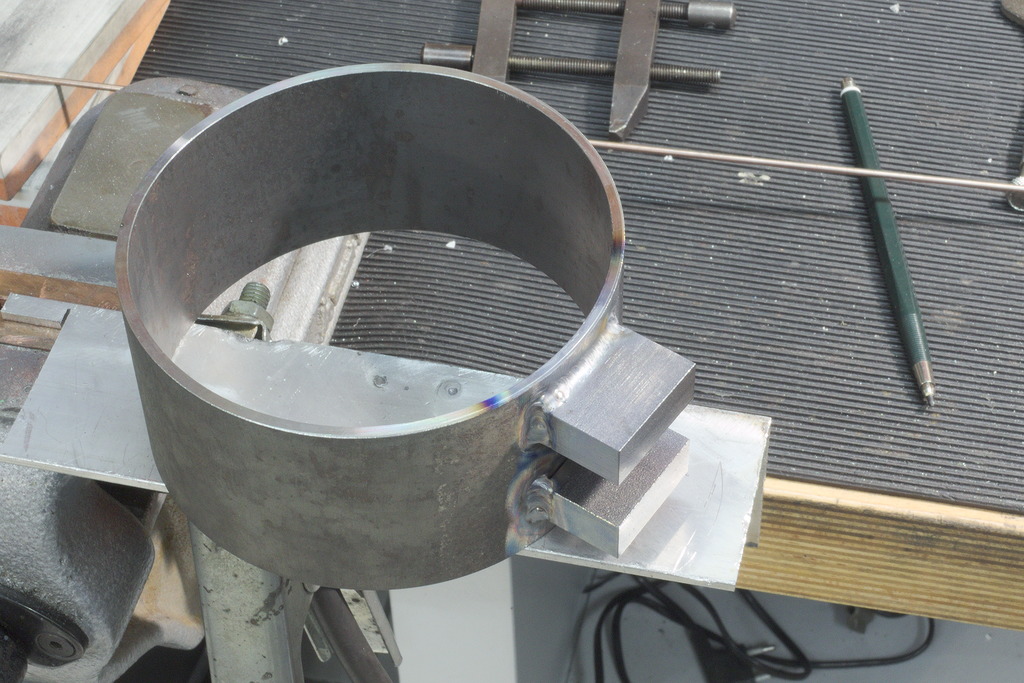

Two lugs where tigwelded onto the pipe:

The lugs where then drilled and reamed to match the overarm support:

The pipe was then trimmed on the bandsaw and back on the milling machine, the lugs where drilled, tapped and slitted to form a clamp:

The new, way more elegant wheelguard in place: