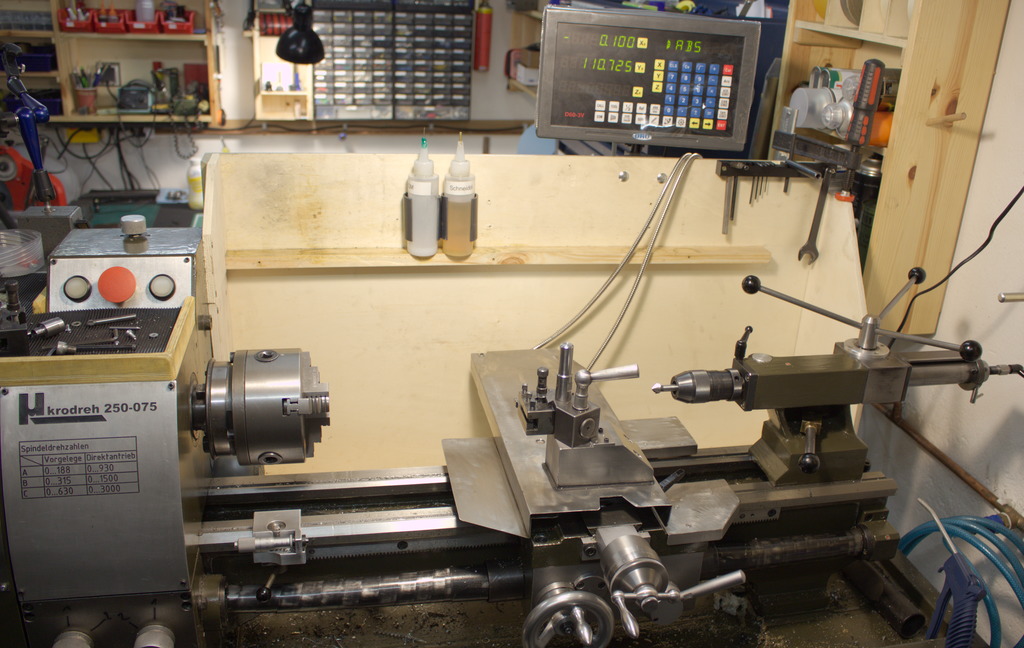

I settled for a Chinese three axis readout (The same unit I use on my milling machine, so in case one fails I can swap them out and continue to work until I get a replacement). The linear scales I got can be set to 5/1000mm, 1/1000mm or 0,5/1000mm increments by adding a jumper in the plug. I set the scale for the carriage to 5/1000mm and the scale for the cross slide to 1/1000mm (On the readout it shows 2/1000mm increments as it is converted to diameter, not radius).

All parts where sourced trough Digitalanzeige-Profi

The scales are large size form factor with a cross section of 22x31mm on the scale (plus the readhead, which is about 18x18mm).

The lengths used:

Carriage: 420mm

Cross slide: 120mm

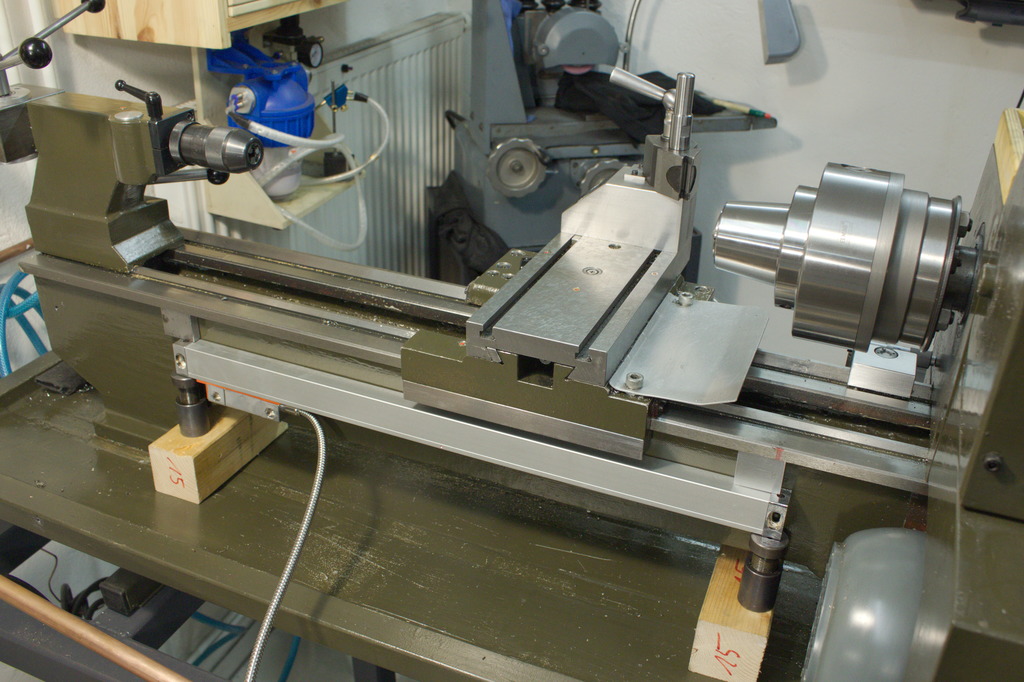

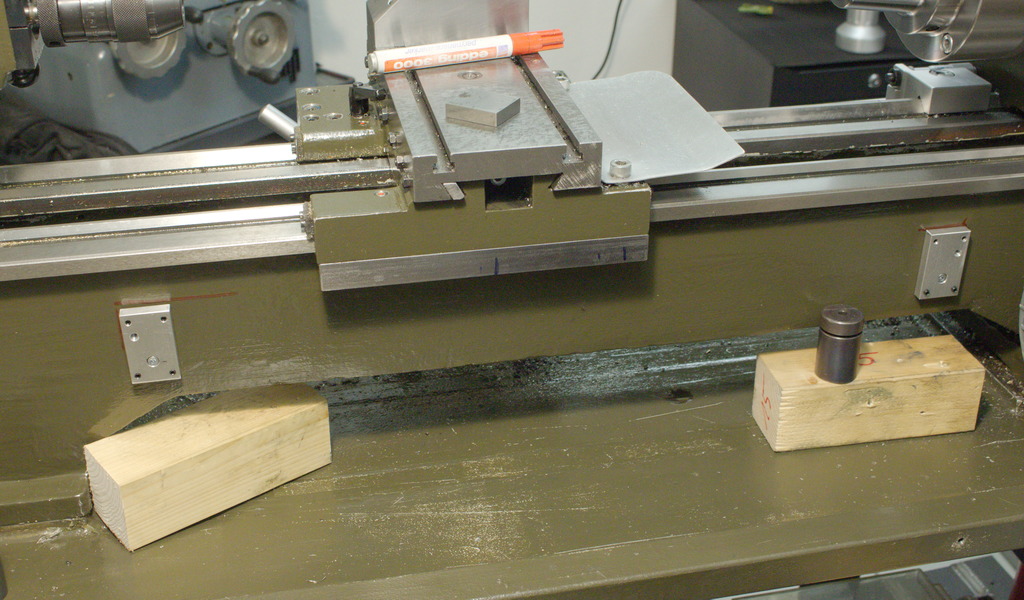

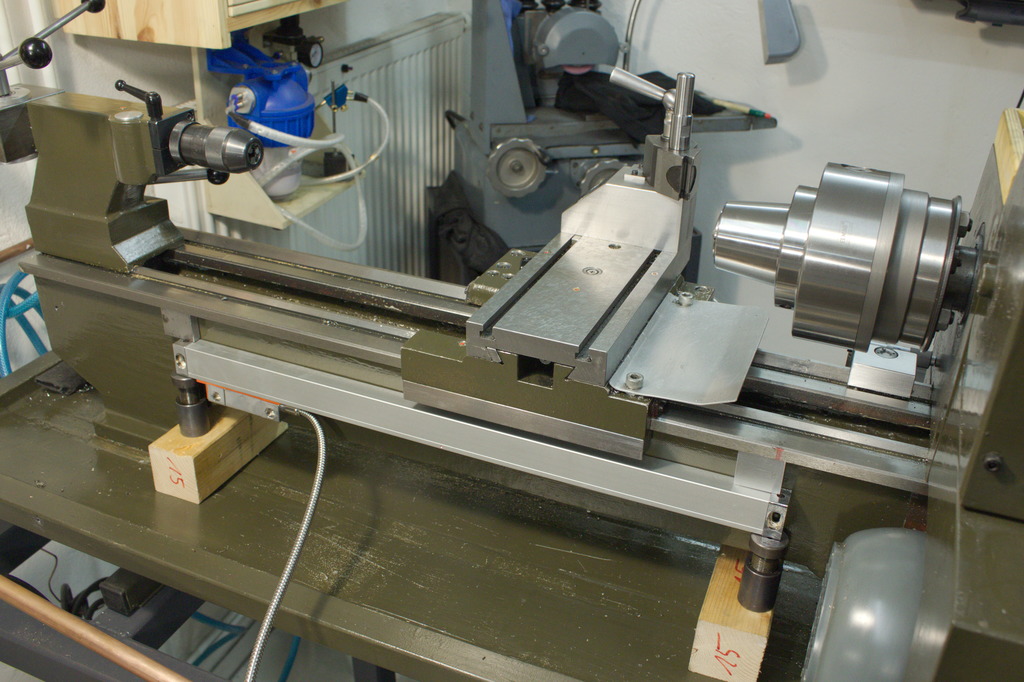

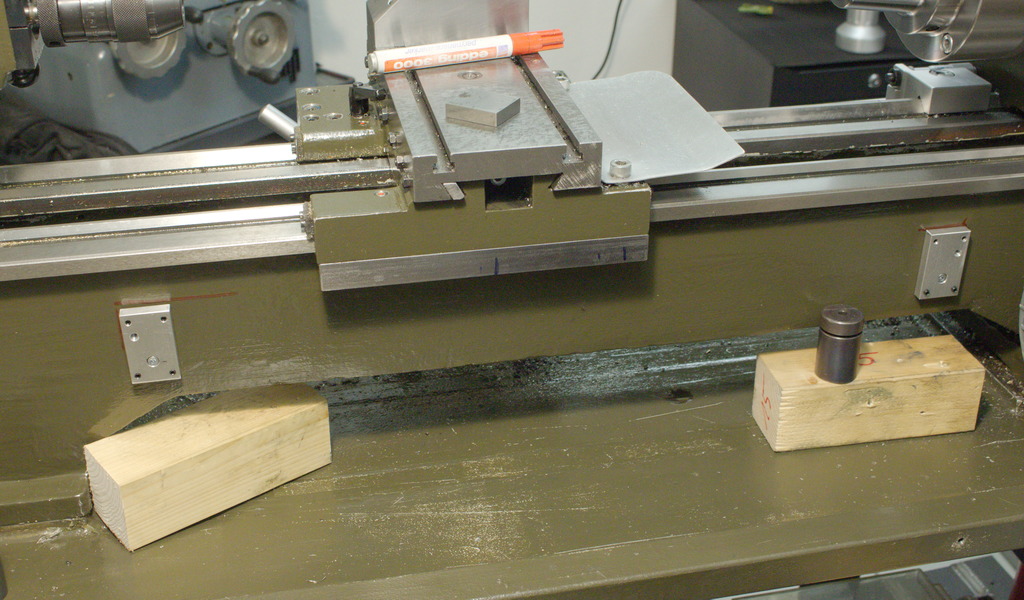

The linear scale for the carriage goes up against the back of the bed – There is no machined surface to mount something, so I machined two pads out of aluminum with a jackscrew in each corner to align them to each other and to the travel of the carriage:

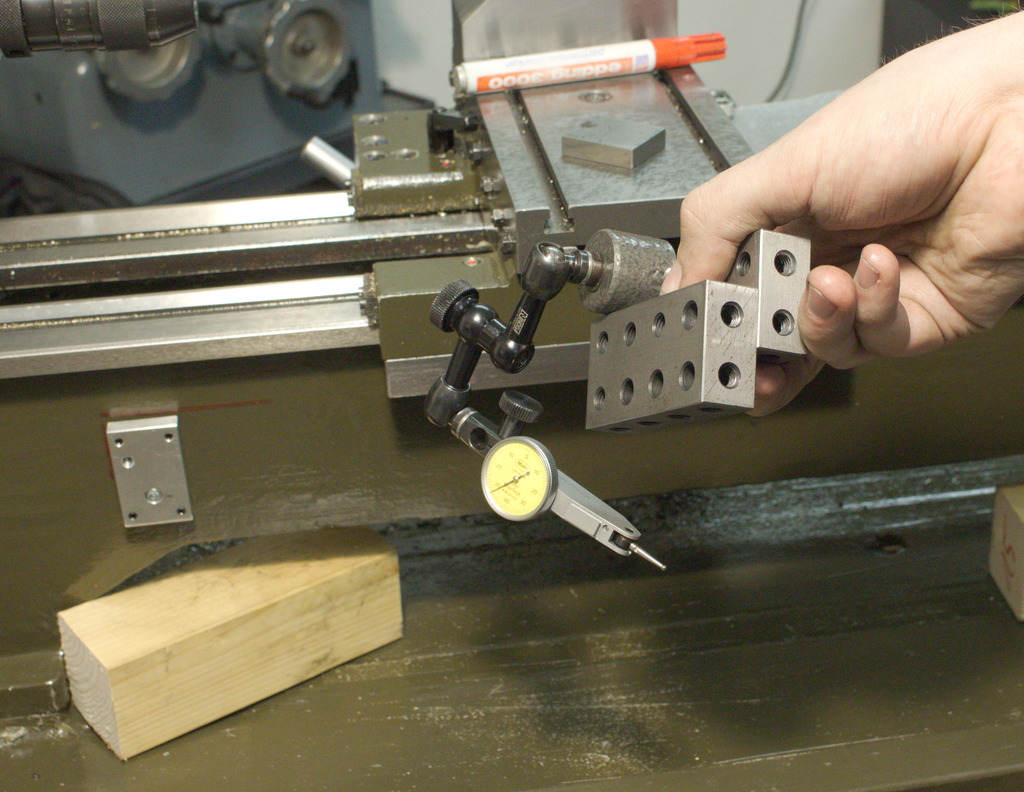

To check the alignment of the aluminum pads, I bolted together two blocks and had my indicator sitting on top of it – Forming a slider than can run along the rear flat way of the bed:

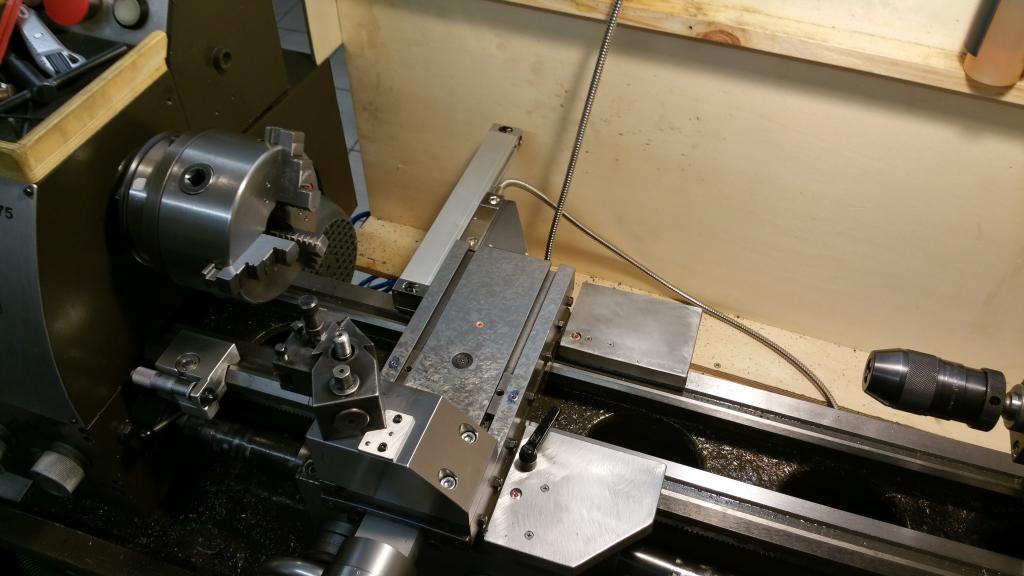

After aligning and mounting the scale I machined a bracket that tied the readhead to the carriage:

Mounting the scale to the cross slide was more of a problem. I wanted it to be on the chuck side of the cross slide and I did not want to lose much working envelope, so mounting it directly under the chuck was not an option.

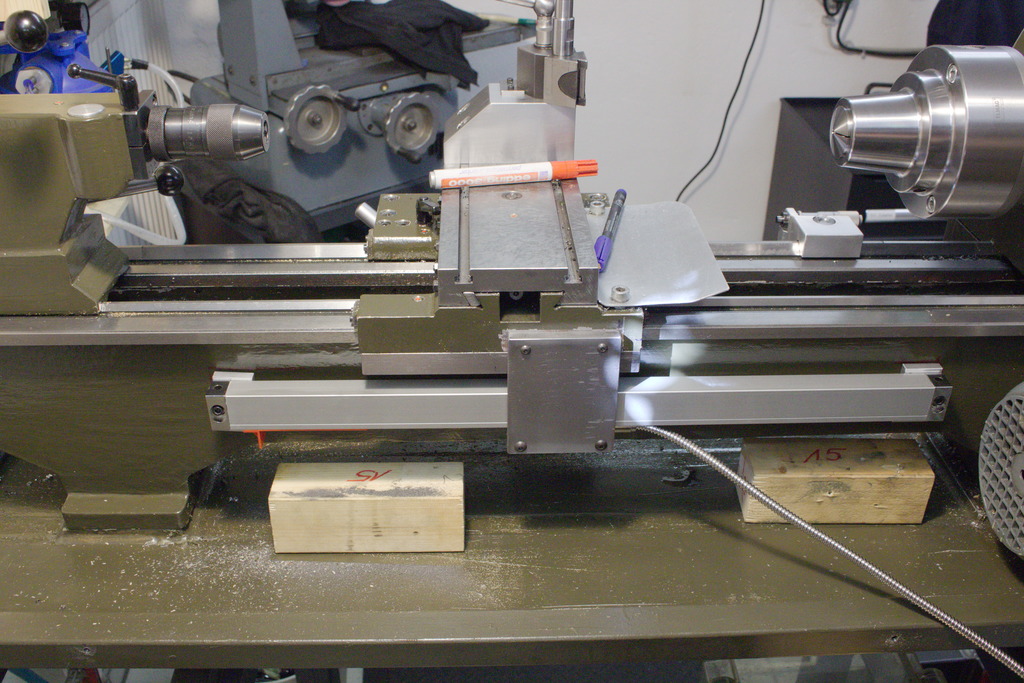

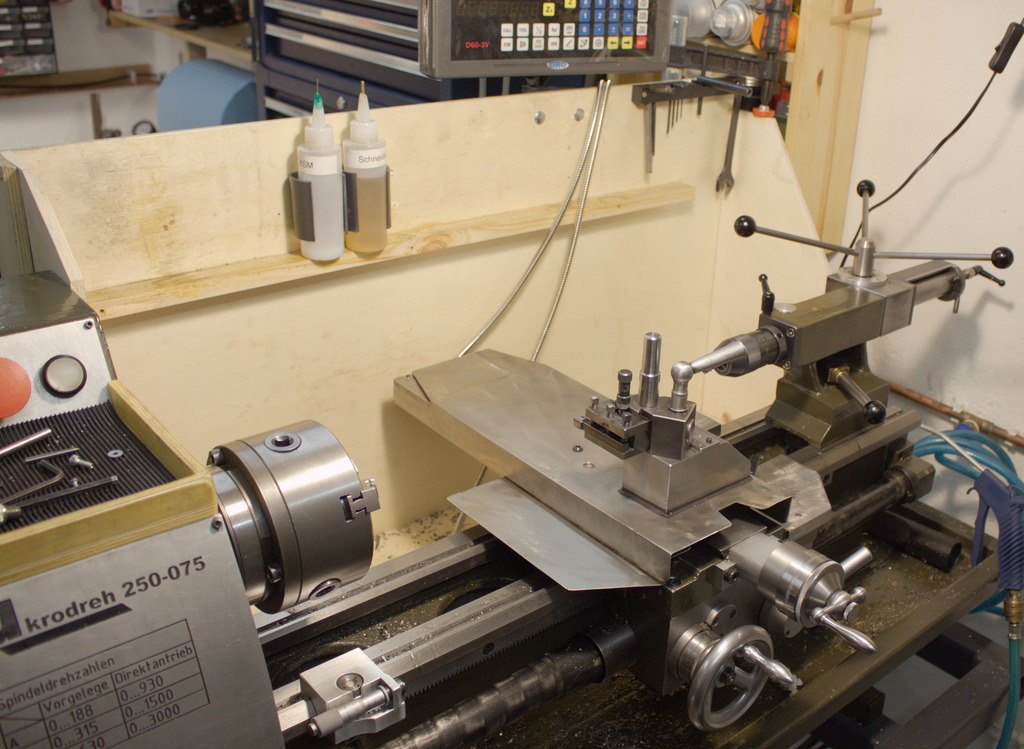

I decided to let the scale overhang to the back, mounted to the carriage and have the readhead follow along with the cross slide. That way I was later able to cover the scale and readhead up completely with sheetmetal covers to protect them from chips, oil and cooleant:

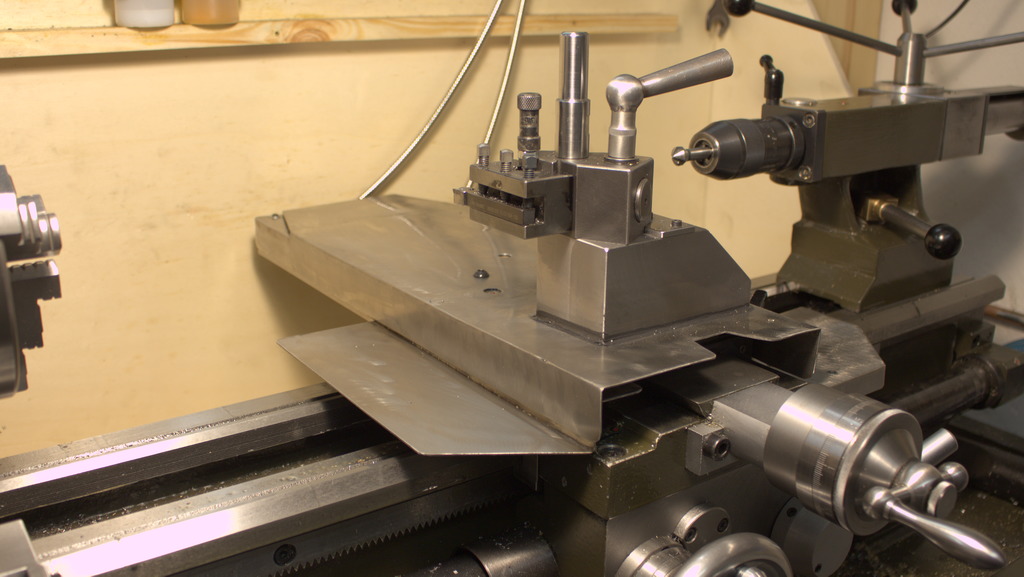

To mount the readhead to the cross slide, I welded up a bracket out of 5mm mild steel and machined the mounting surfaces perfectly square. It bolts to the rear of the cross slide, below the top surface:

A sheetmetal cover was fabricated out of 1mm stainless – It folds around the scale and is mounted to the carriage:

The whole cross slide is covered with a second sheet metal cover, reaching around the stationary cover over the scale. This forms something like a labyrinth seal and gives more protection to the scale.

As an added benefit, a good amount of the exposed ways are now covered up:

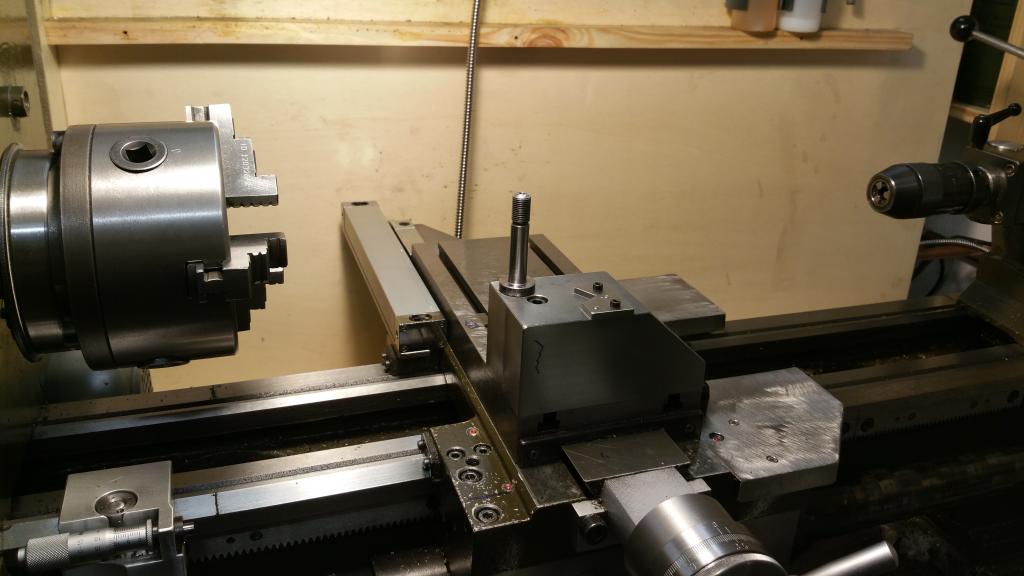

After mounting the scales, I had to modify my rear chipguard due to the large overhang of the x-scale. I ditched the sheetmetal guard and went with 10mm plywood – I might cover it with aluminum sheetmetal (Faster to work with, I can cut it to size with the tracksaw) so it does not get oily/dirty all over:

Last thing that was added are leather way covers - I used leather on my cnc mill in the past and it held up to oil, cooleant and chips very well. With those covers, the ways are completely protected: