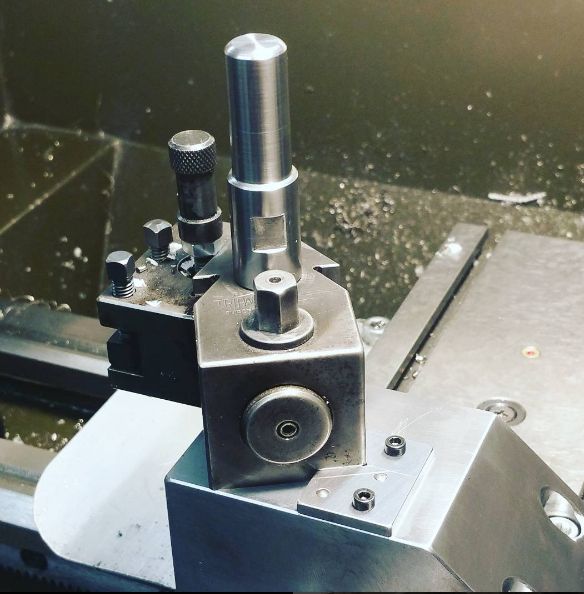

The block has two big advantages for me:

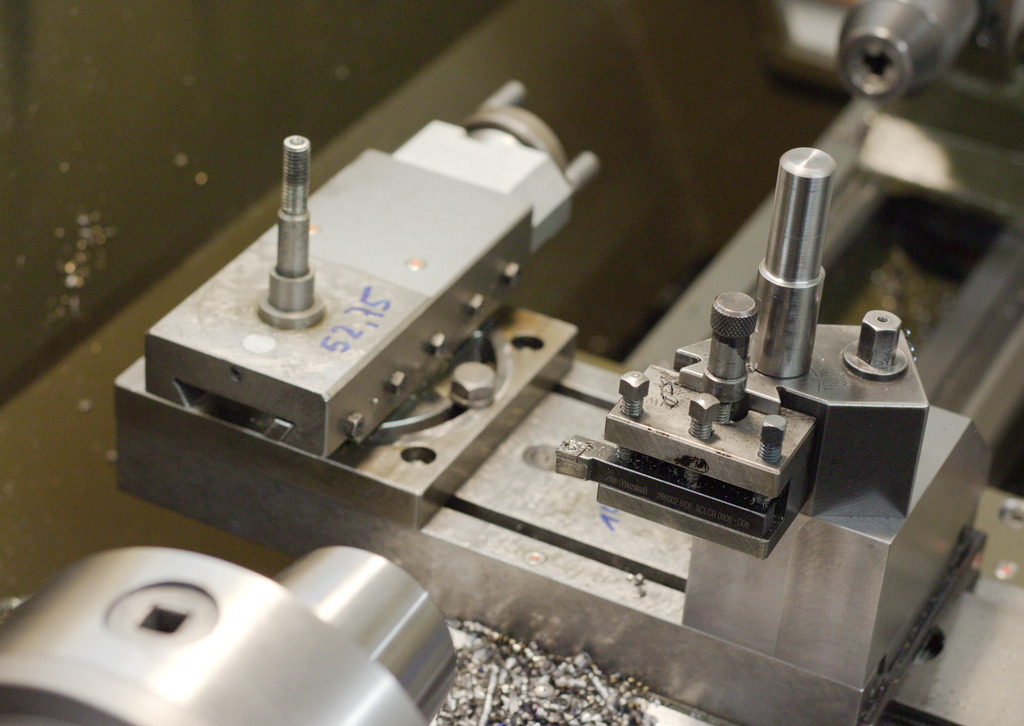

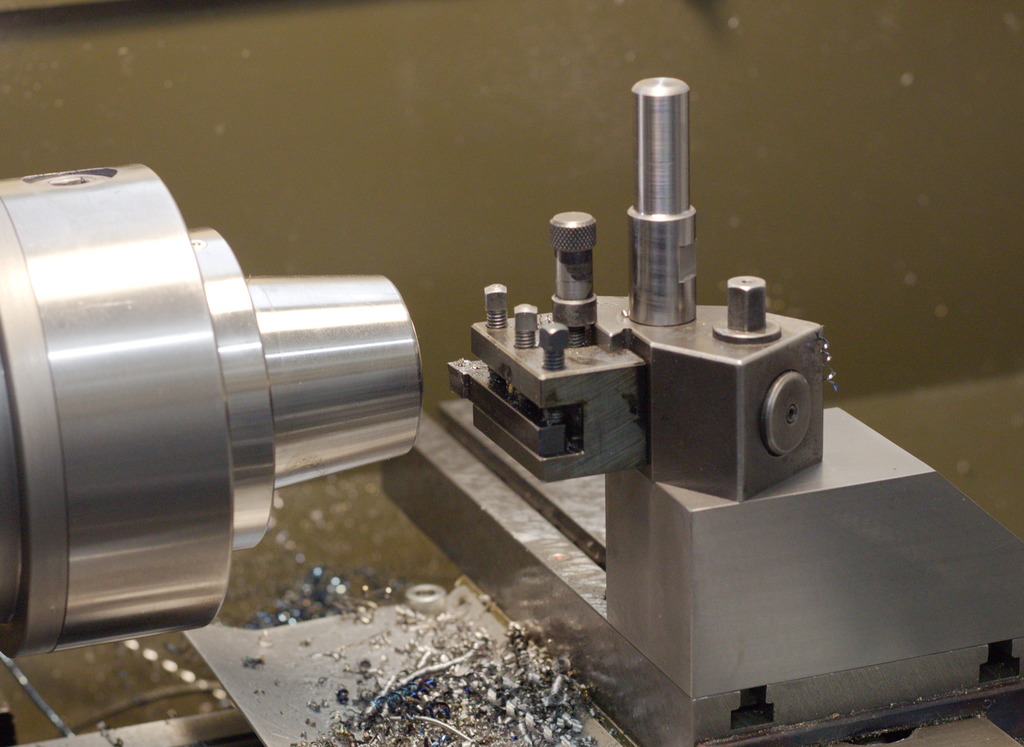

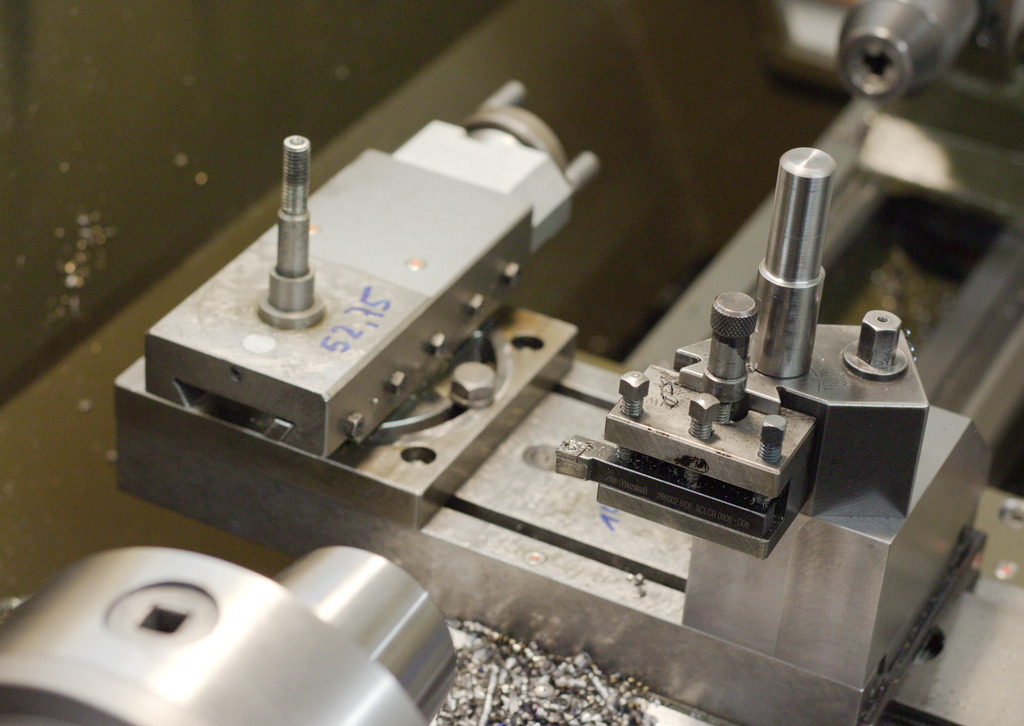

If I need the top slide, it is possible to mount it temporary on the rear of the cross slide and swap the Tripan qctp over:

The long nut that holds the qctp in place has also a use - It is a nice rigid hardpoint to clamp an indictor to:

The position of the Tripan qctp is locked in position with a notched plate, that is screwed and pinned in place:

An argument against such a fixed block instead of the compound is threading, you cant feed along the edge of the thread, like you would with a compound swung around half the included angle of the thread.

But as I do mainly threads with smaller pitches up to 2mm it is not a huge deal for me - And if I have to do some heavy threading, I can still drop the compound back on.

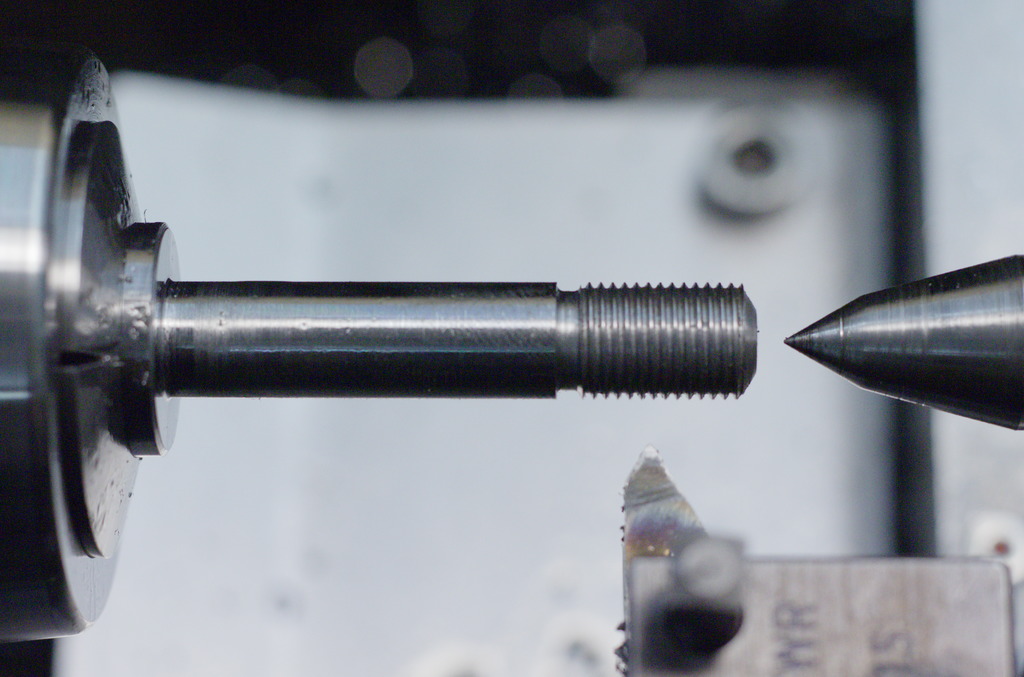

An example of a 10x1mm fine thread in 42CrMoS4 steel with straight infeed: