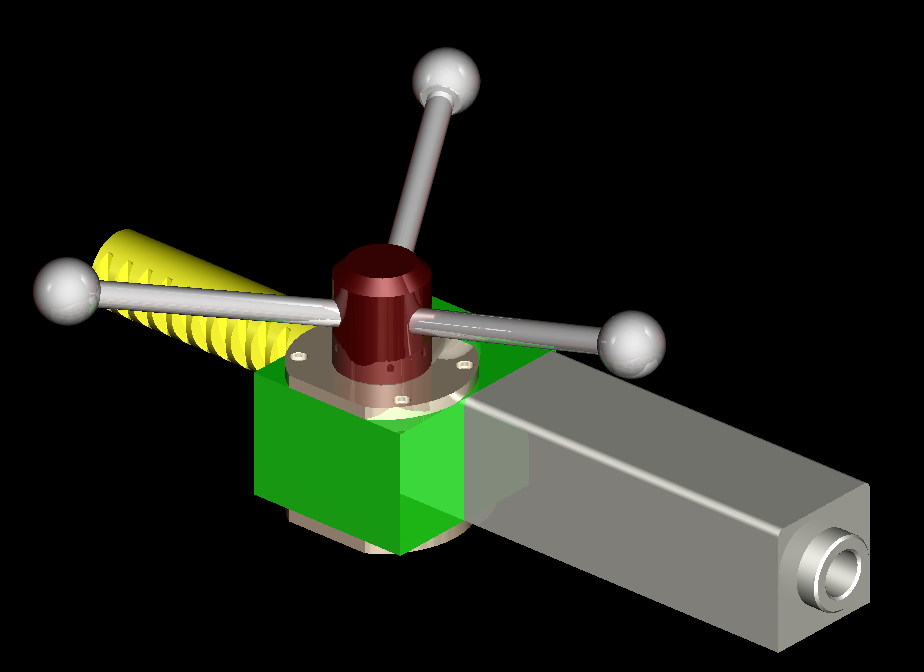

I wanted to extend the existing tailstock ram with a piece of round rack, which is readily availible trough various industrial suppliers and mount a gearbox on the end of the tailstock casting. While working on the tailstock, I also decided not to use the original lock for the ram anymore but make a new one that doesn't push the ram out of center.

These are the parts, the casting, the round rack, the orginal ram and the pinion:

The end of the rack got machined down and the end of the original tailstock ram was bored open in the end to accept the rack. Both pieces where aligned on the surface plate and joined with Loctite 648. You see an assortment of ground blocks and a large square to keep the elongated quill straight untill the glue has set:

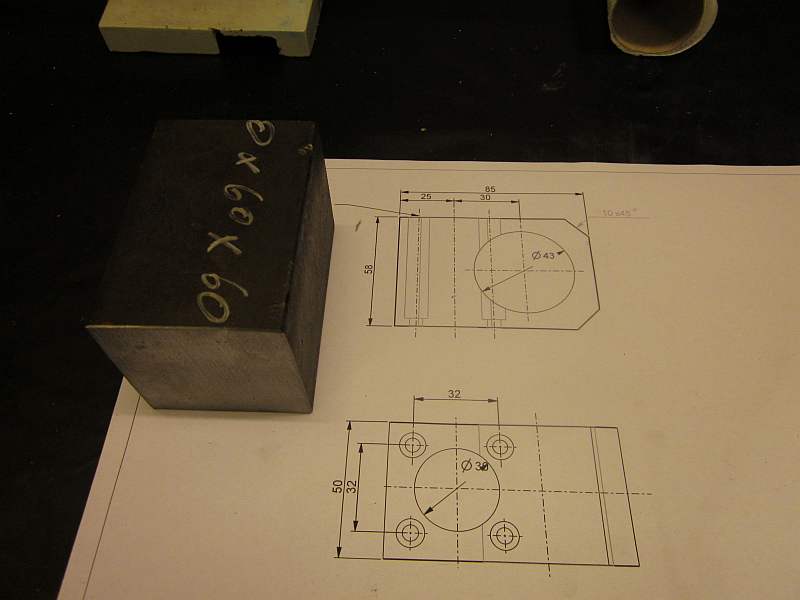

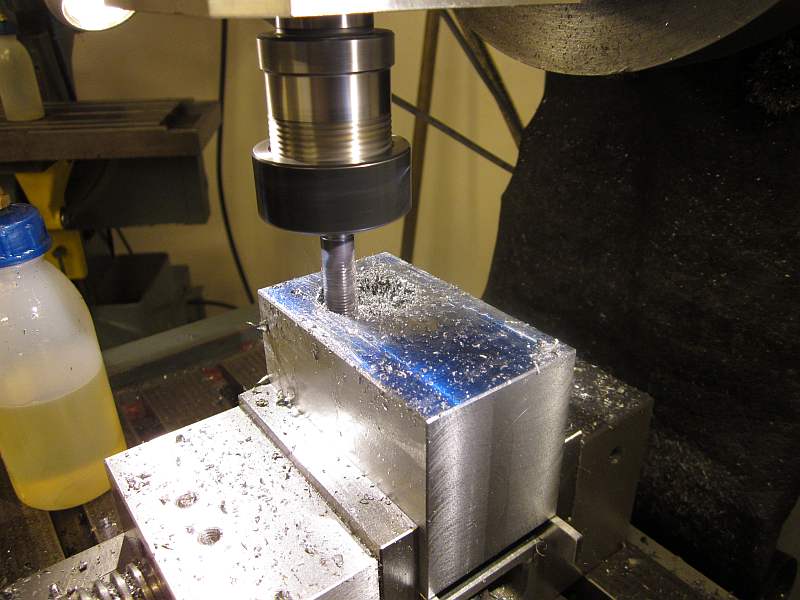

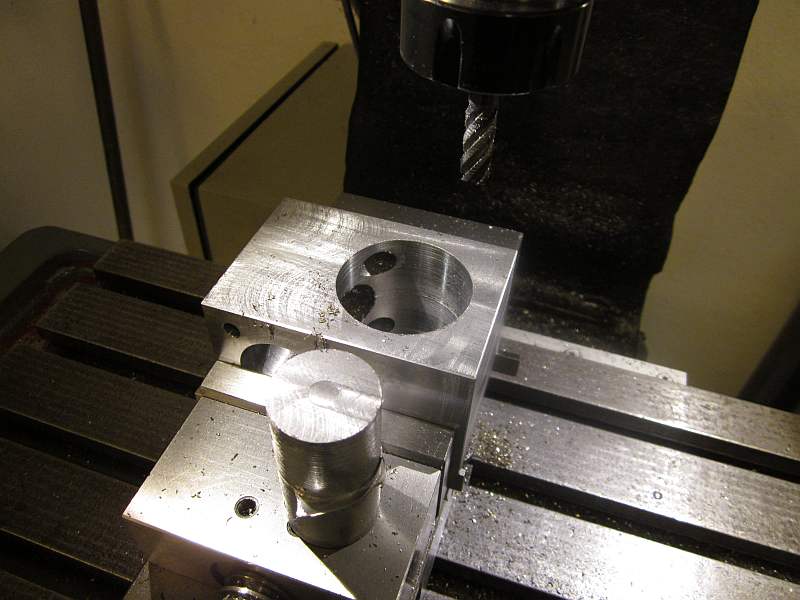

The gearbox is machined out of a piece of mild steel and the bore for the ram is roughed out via helical milling:

The bore for the ram was to deep for my Wohlhaupter UPA1 which only accepts boring tools with 8mm shank, so I decided to use a solid boring bar with a brazed carbide toolbit. I preset the tool, sitting in a v-block on the surfaceplate with the indicator to the desired diameter:

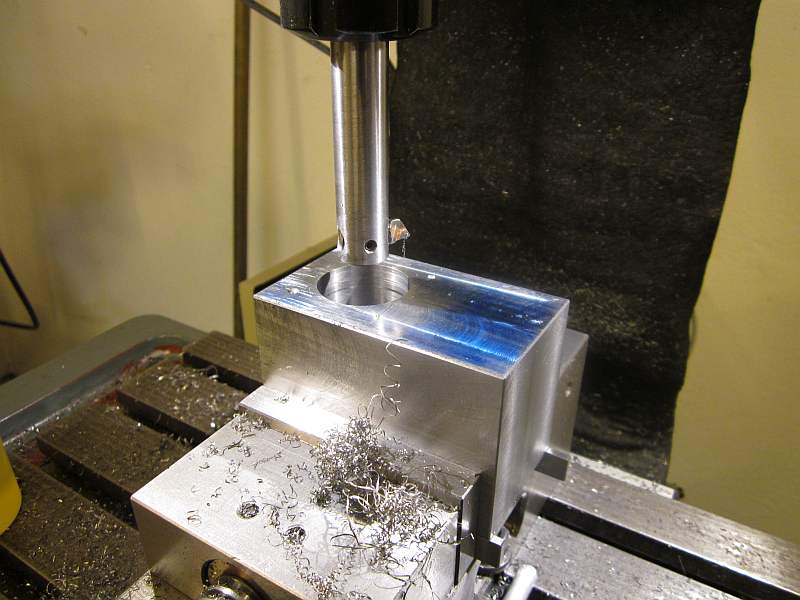

The bore for the pinion was also roughed out by helical milling and then bored to final diameter with the Wohlhaupter boring head, as the bore was not that deep:

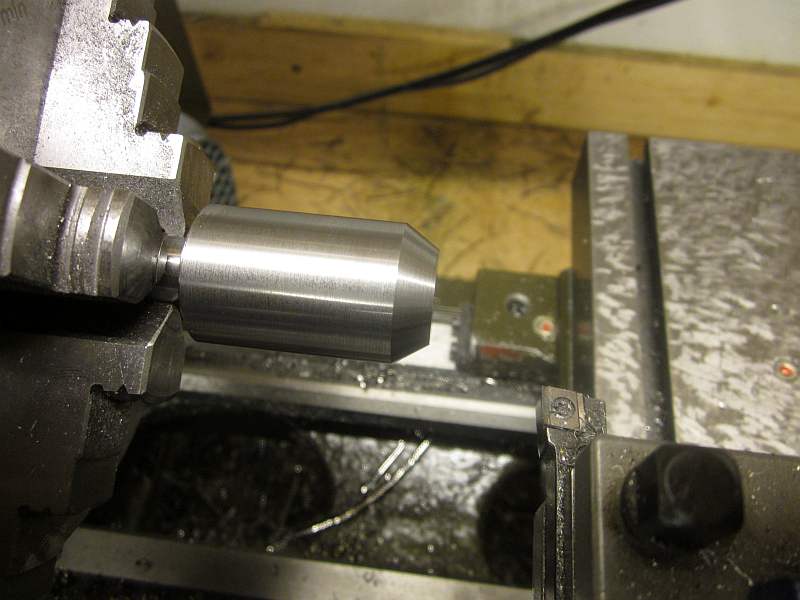

The bearing caps for the two deep grove ball bearings where machined out of aluminum and the bearings shrink fittet into them. After a quick testfit of all the parts I machined the shaft for the pinion:

This is the new quill lock, its just a plate, bored to a close fit around the quill and then splitt. It is bolted against the face of the tailstock. By pinching the bore with a clamping screw the quill can be locked securely in place, without moving the quill in the tailstock very much (That is a problem with the original lock, as the two cotters pushed the quill a good amount out of center.):

The slot that prevents the ram from rotating had to be extended. For aligning the existing keyway slot square to the machine I used a stack of gage blocks and a square:

Of course the tailstock had to be drilled trough so it was possible to eject the morse taper tooling from the rear with a pushrod. Later I added a M12x1mm fine thread to the end of the ram and made a push rod with the same thread. That way I just need to screw in the pushrod a few turns to push out the tool.

My experience after a few years in use is great - The tailstock is a joy to use. The elongated ram is way more stable, as its always supported over the full lentgh of the tailstock bore, I have more quill travel, drilling small holes under 0,5mm diameter is very easy, deep hole drilling got faster as retracting to get the chips out is so much faster than on a normal cranked tailstock. Overall absolutely worth the extra work.

A friend of mine did the same modification to his lathe too (pretty much the same model) and he is very happy with it too :-)