I have a video where I show the new depth stop in detail:

Precision depth stop

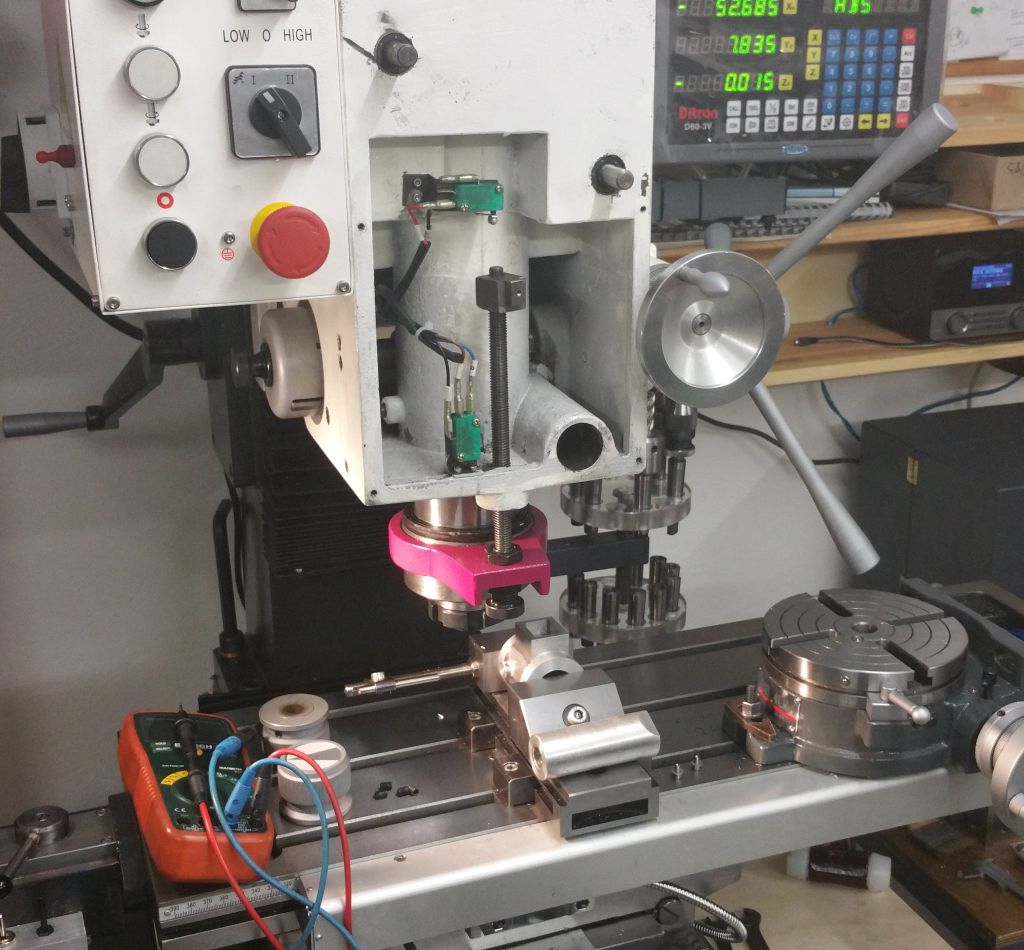

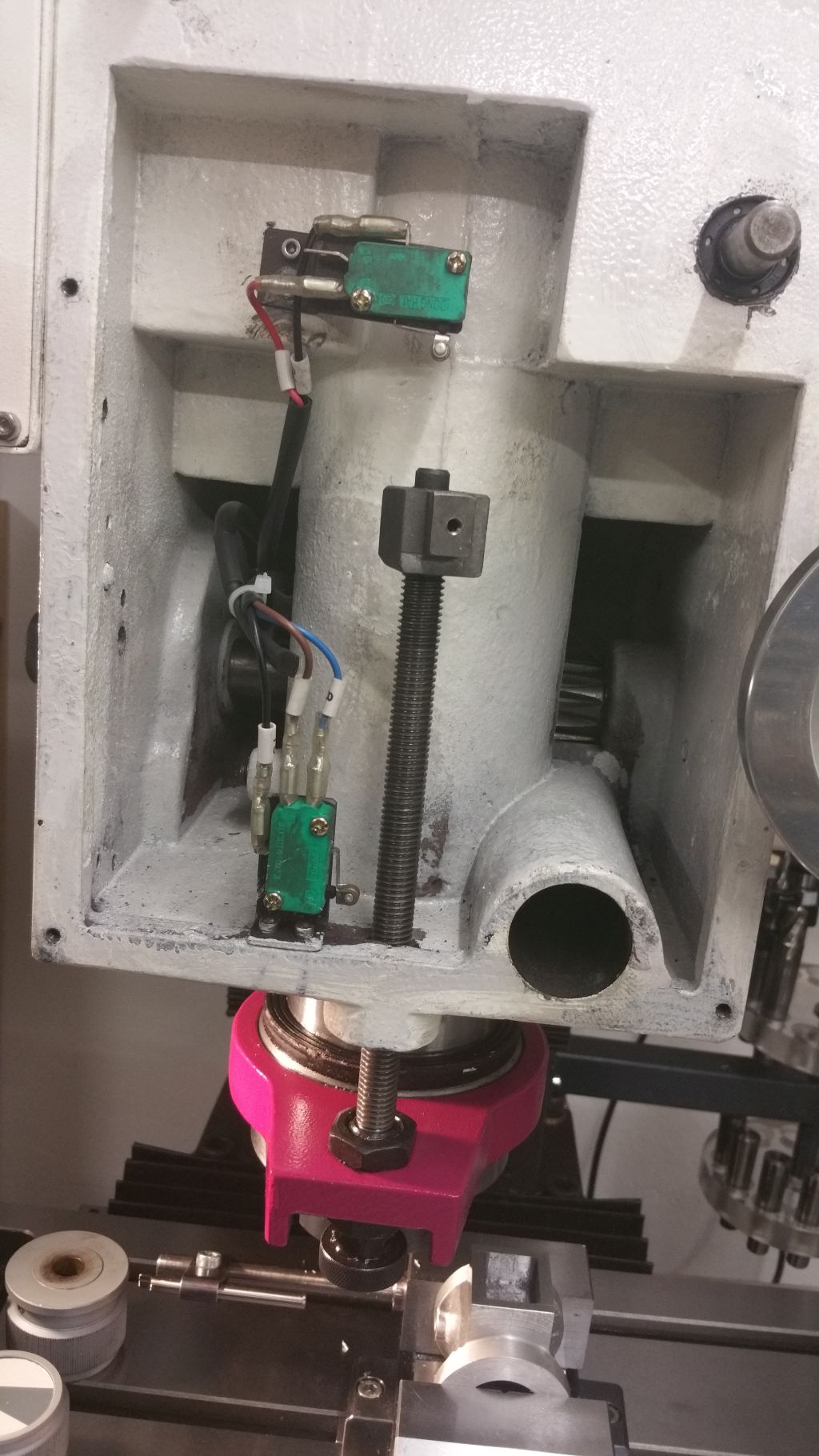

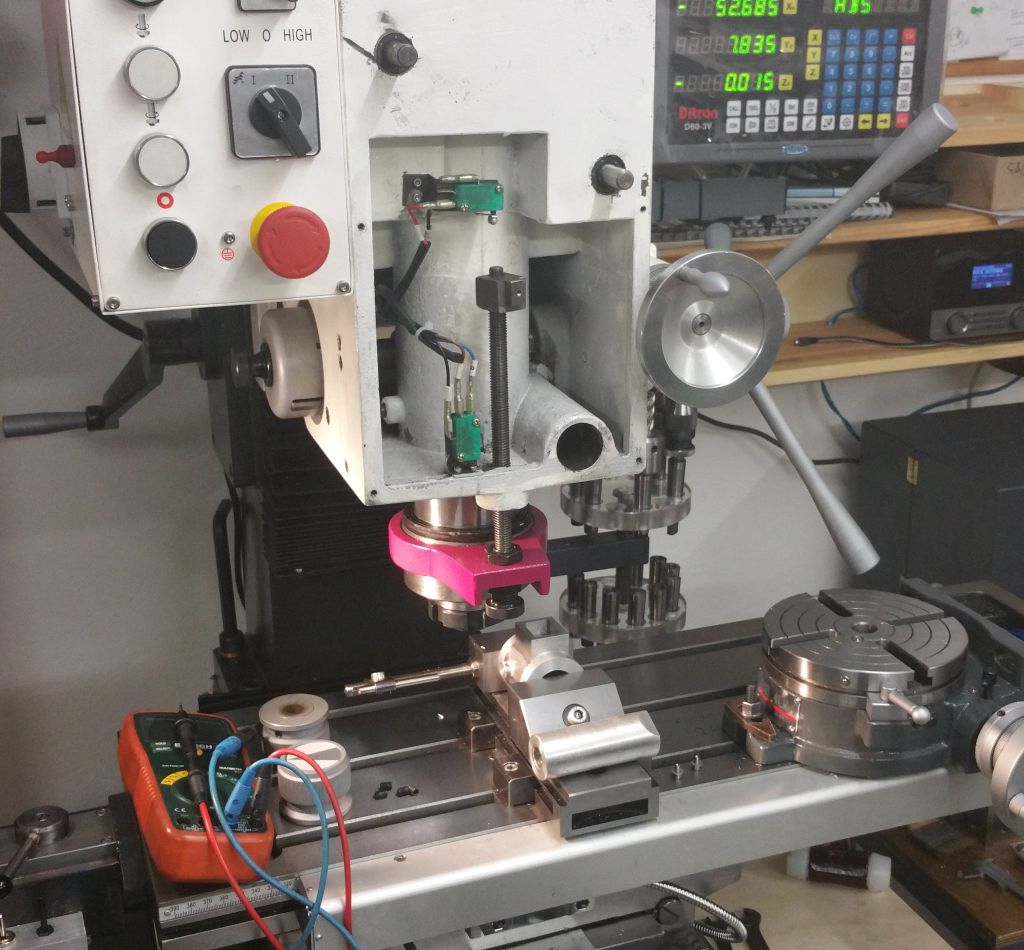

I wanted to modify mine, so I took the front cover off and then you can see why it is so bad - The depth stop is a threaded rod that has its bearing in the ring around the quill, with a lot of axial (and radial..) play. No way to get that thing to any reasonable amount of precision:

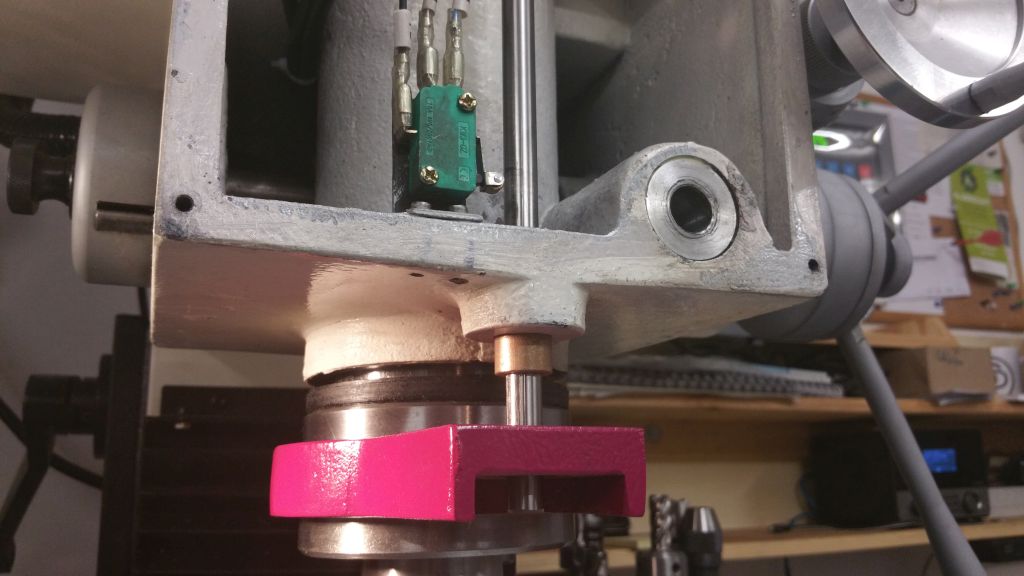

I removed the threaded rod and played around with some pieces of drill rod and bronce bushings as a replacement:

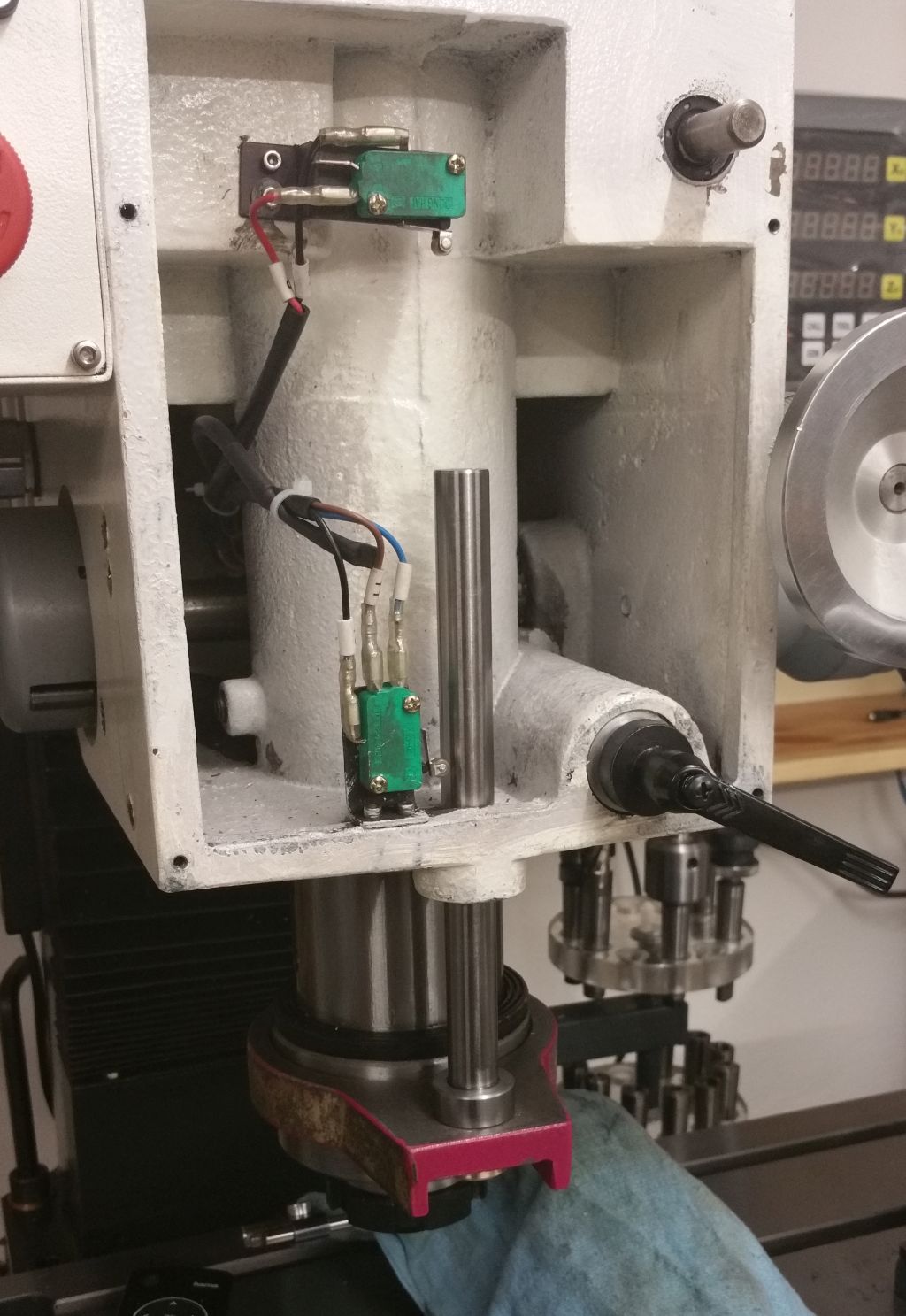

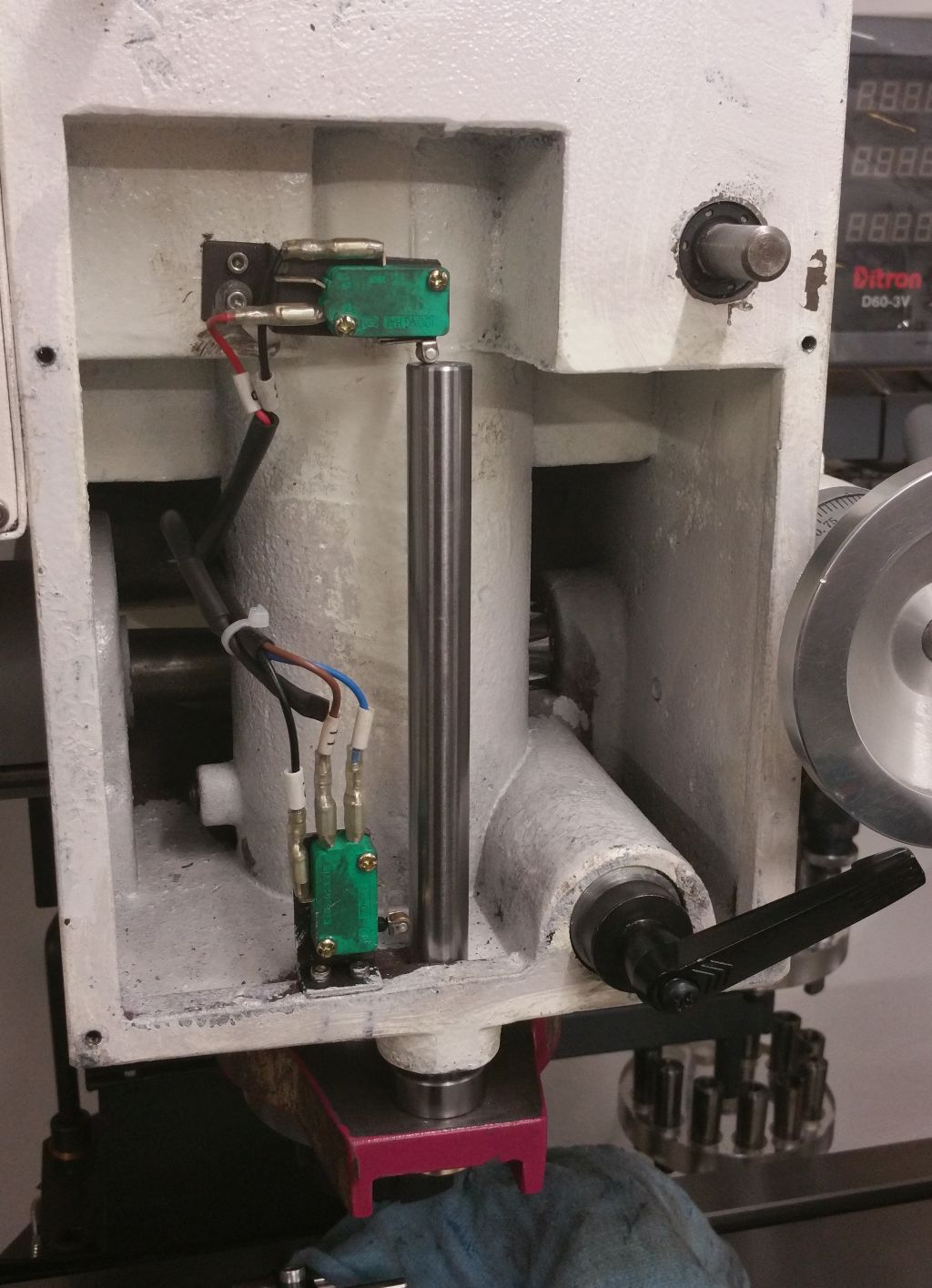

Then I realized that the bore, that the original depth stop went trough, had exactly 16mm - So I took a piece of linear rod, which is hardened and ground and it fitted very good. I made a mount for it to go on the quill ring and I was a big step further - Now I had a solid and firm mounting point for a depth stop.

The ground rod as a replacement for the threaded rod had another advantage: Before the modification, the Quill was able to rotate slightly, but now, with the tigh fitting rod, there is not much play left:

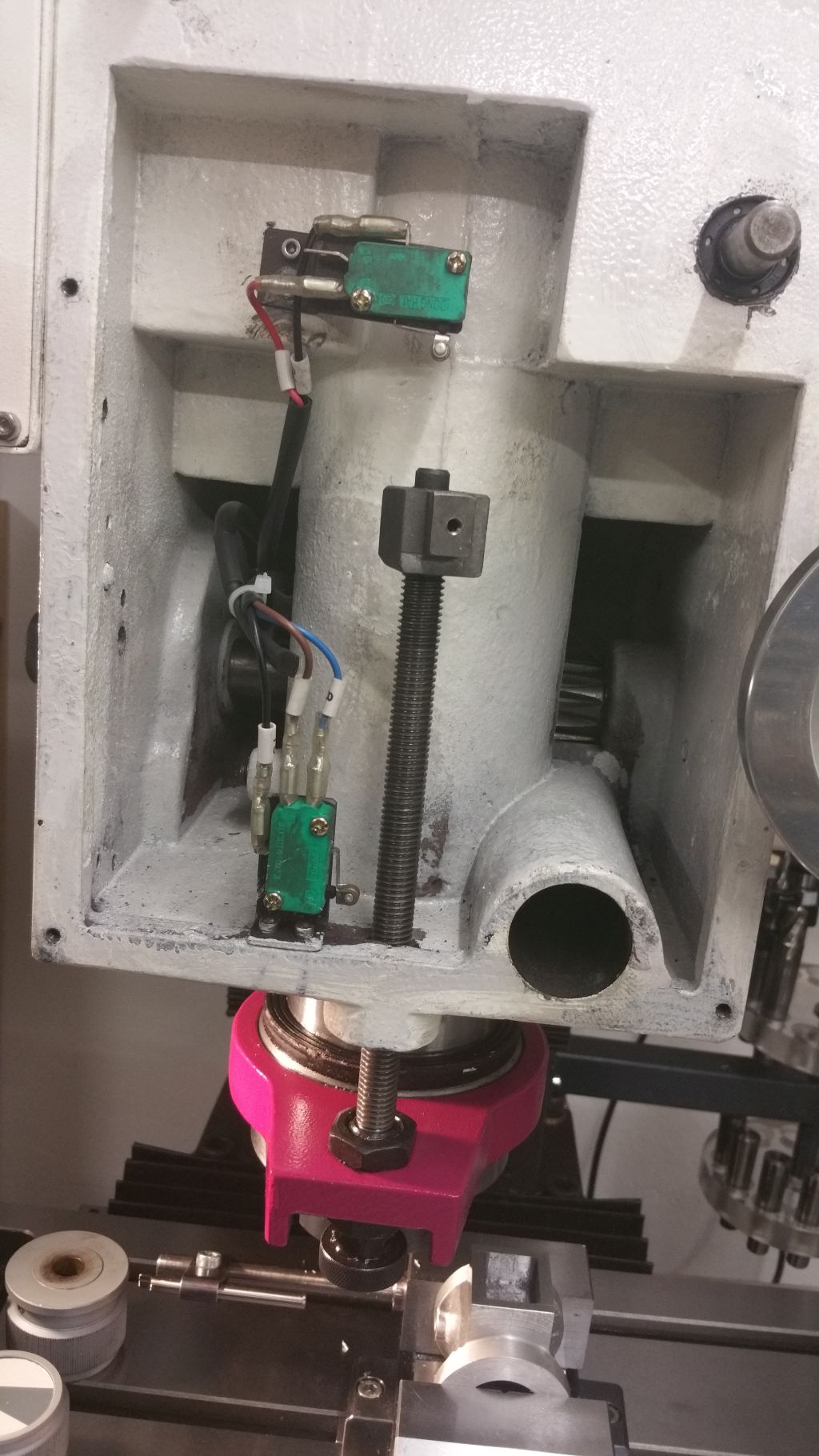

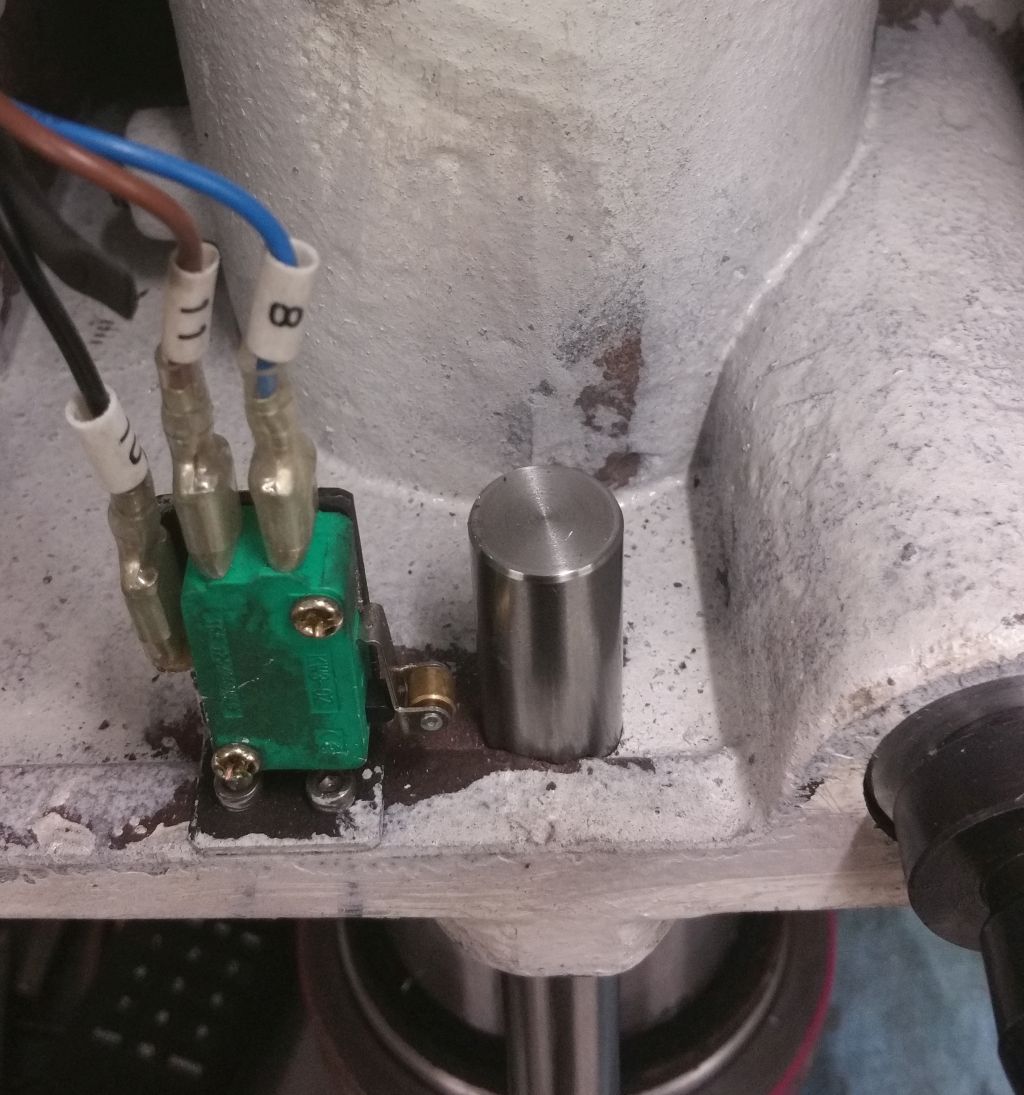

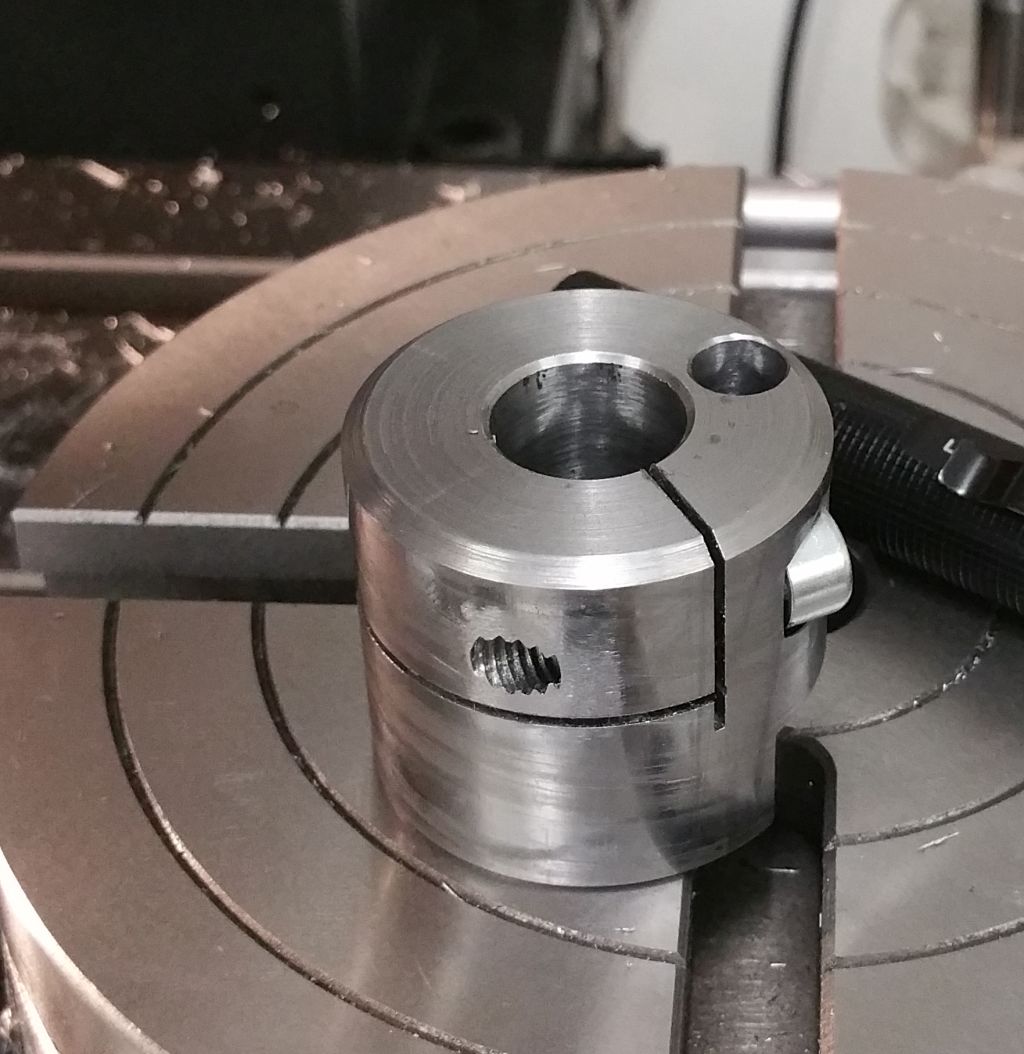

As all surfaces where only cast, I turned a ring with a 16mm bore that fitted tighly over the new guide rod:

I put some wax mold release on the guide rod and used some steel filled epoxy to cast the ring in place:

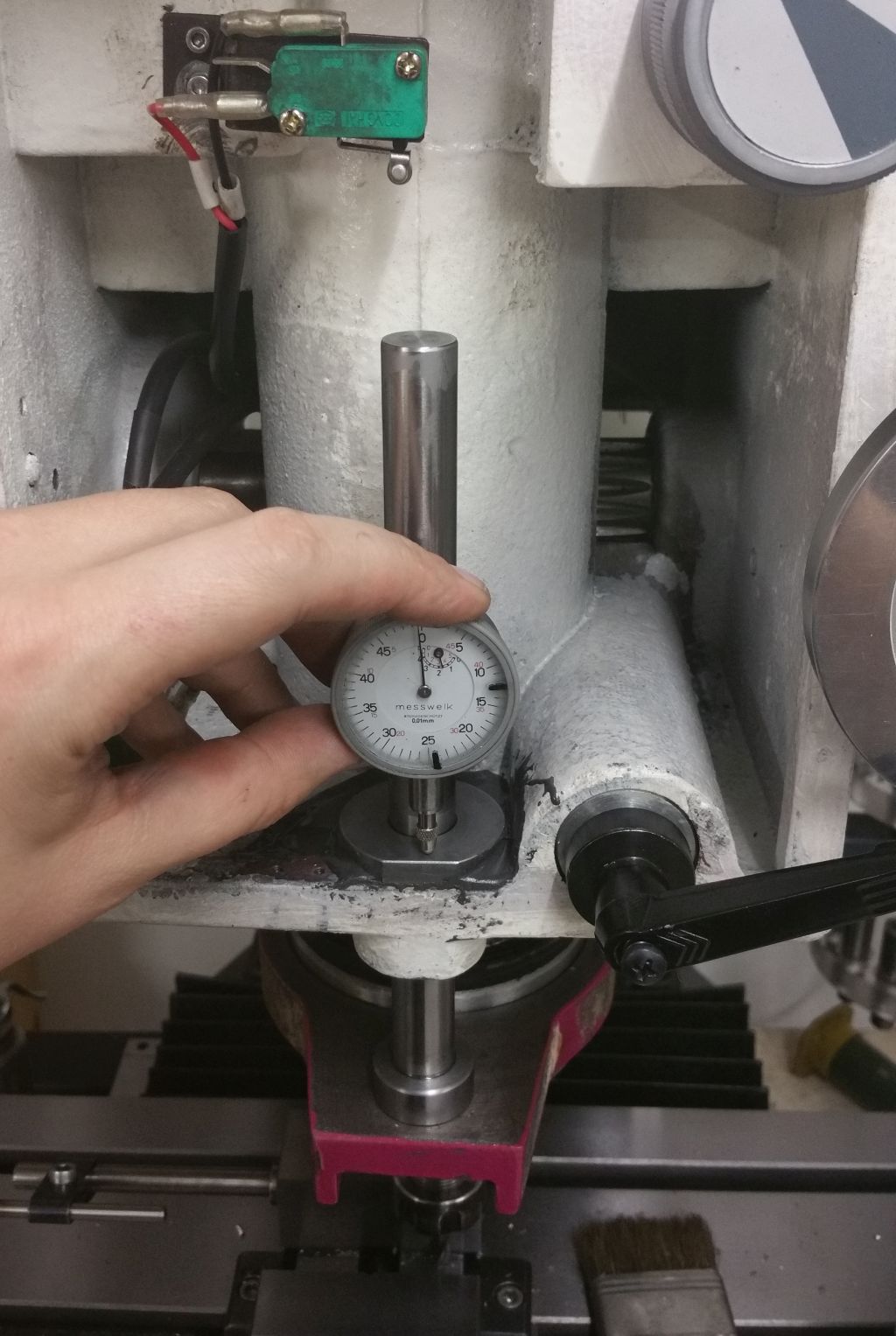

Now I had a good surface that I could use as a reference for a dial indicator:

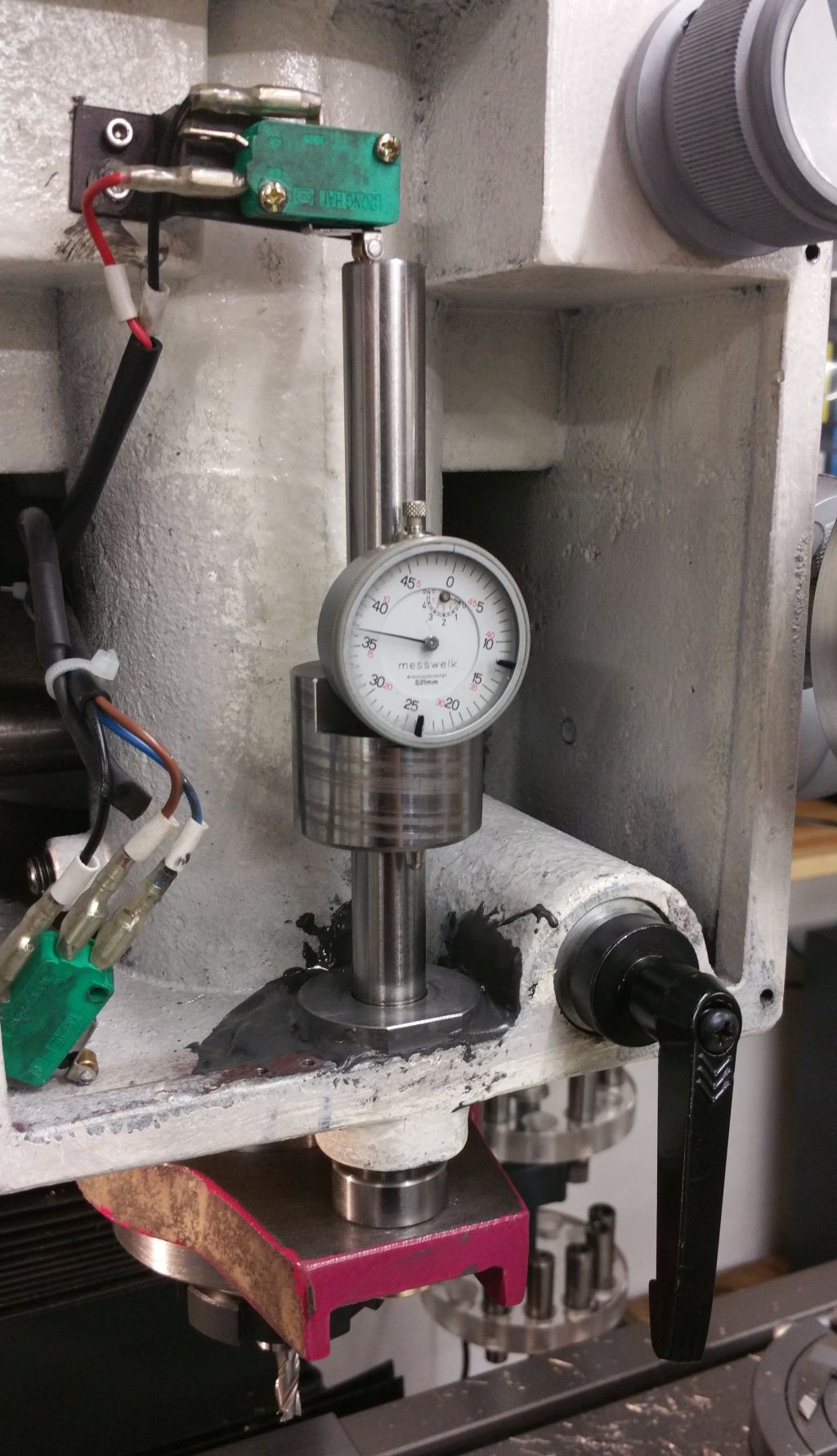

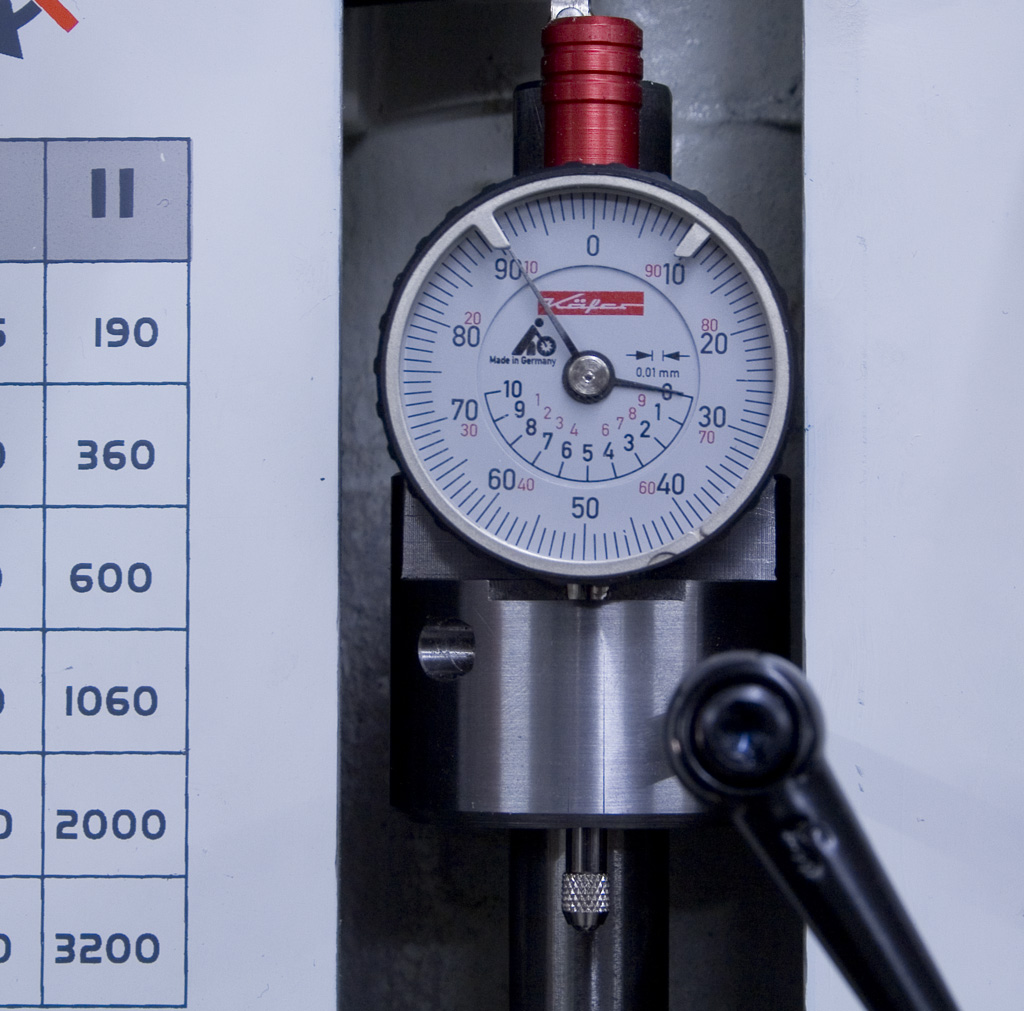

I made an adapter to hold a small indicator that can be clamped on the guide rod:

The cutout in the front panel had to be milled out slightly to make room for the indicator:

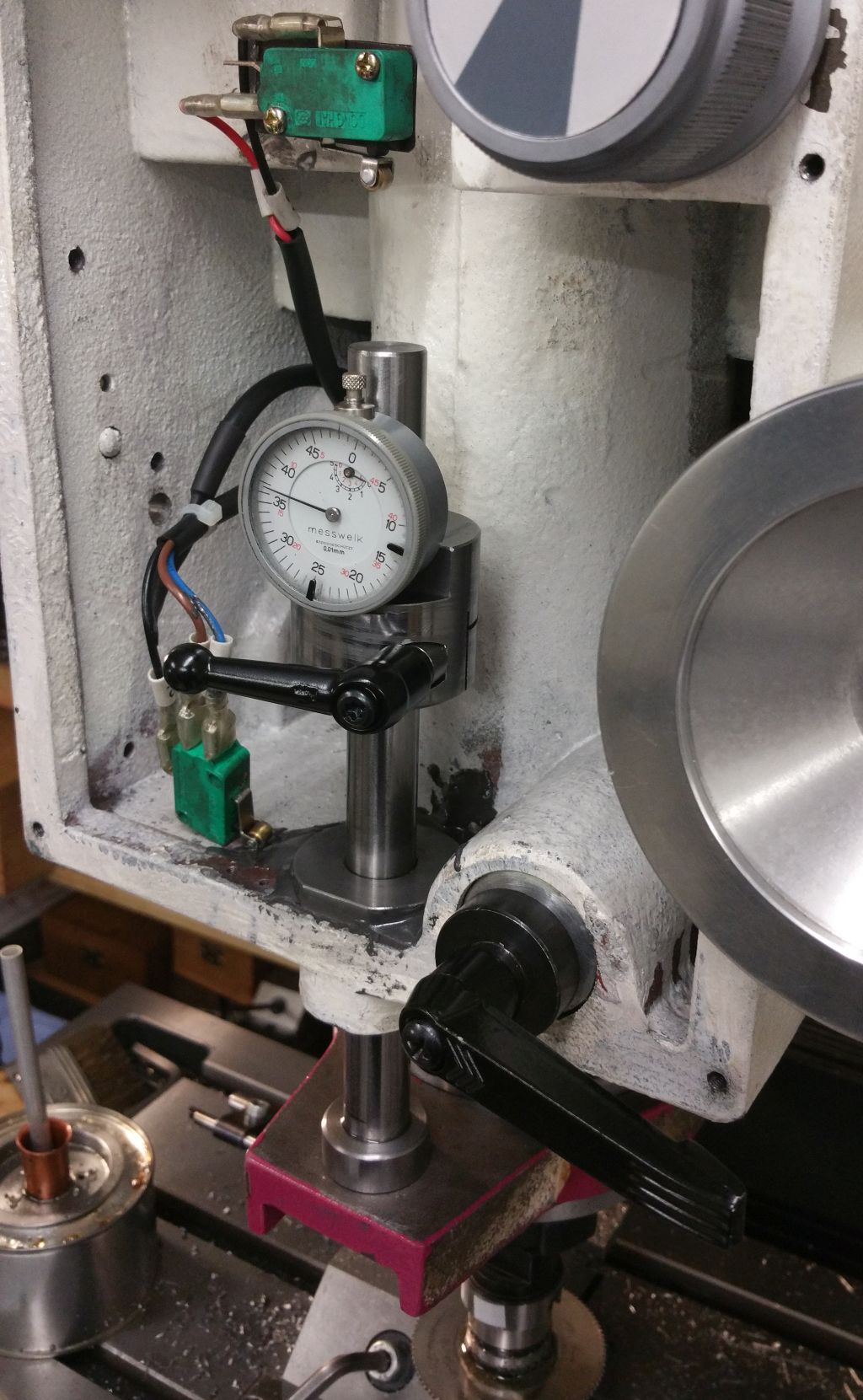

Last thing I did, was to order a new indicator, made by Käfer with a 40mm dial and 10mm travel:

The modification to the depth stop is perfect, you can set it very fast using gage blocks, you can use the indicator to feed the quill in very precise for milling and everything is accurate to about 1/100mm.