Gas springs for the mill

Pretty quick after I got the milling machine and used it for some time, I realized that the downward movement of the head was a bit jerky, it tended to jump 5/100mm instead of moving smoothly. I thought that taking away some weight of the head with a counterweight would improve that behavior and also make cranking the head up and down easier.

A friend of mine, who has the same milling machine had some spare gas springs and some mounts for that he gave to me.

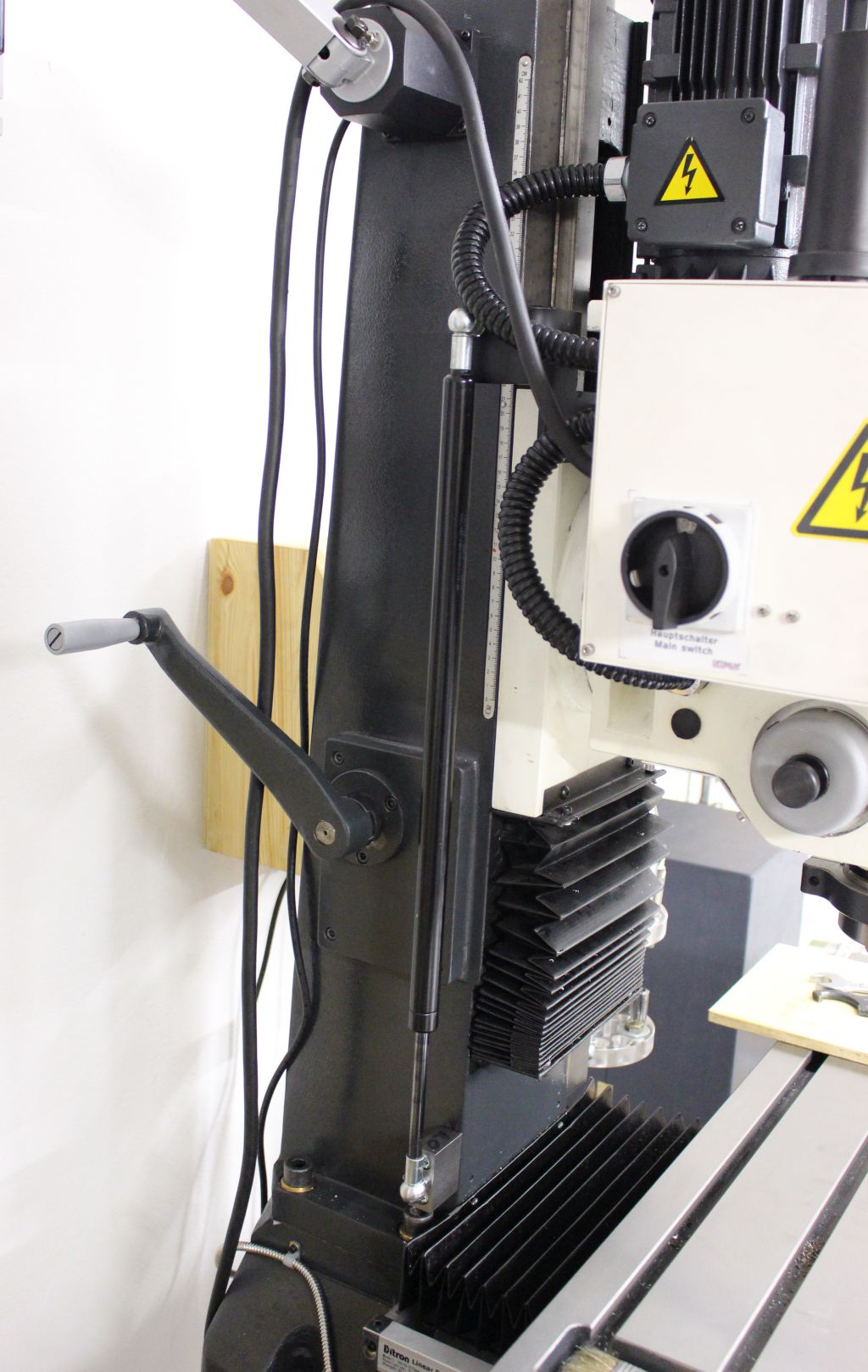

The gas springs have a rating of 350N each.

To mount the gas springs, the head of the machine had to be taken of - It weights about 80kg.

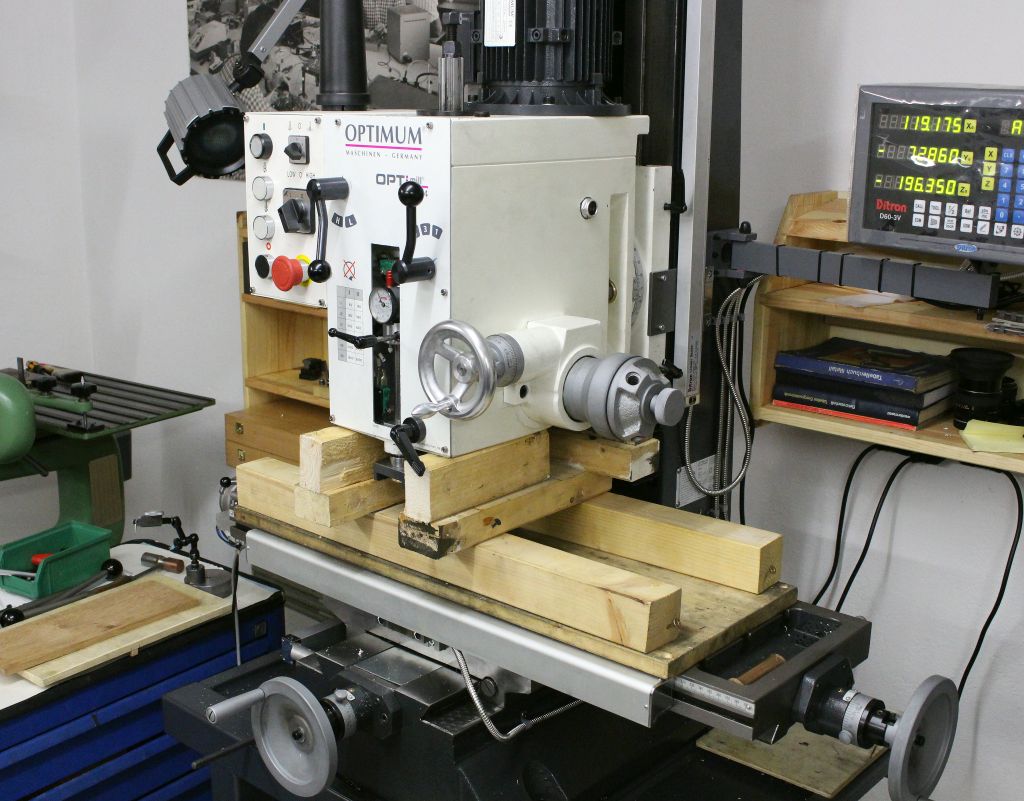

I don't have a crane to lift the head of the machine, so I have to improvise. I use wood blocks to support the head in its lowest position against the table of the machine. Then I unscrew the head, move it of the mounting flange and then I can move it to the side by moving the table of the mill:

Here you can see how the gas springs are mounted to the base of the column with a spacer block on each side and a bracket on the top of the vertical slide which is made out of 6mm sheet metal:

The modification works out very well, the downfeed is now very sensitive and I can use the complete Z-axis to set the depth of cut and also for boring without having to use the quill. There is nothing wrong with using the quill for those tasks but with heavier cuts and large overhang on the quill you will bellmouth the quill bore and the side to side play will get bigger and bigger.