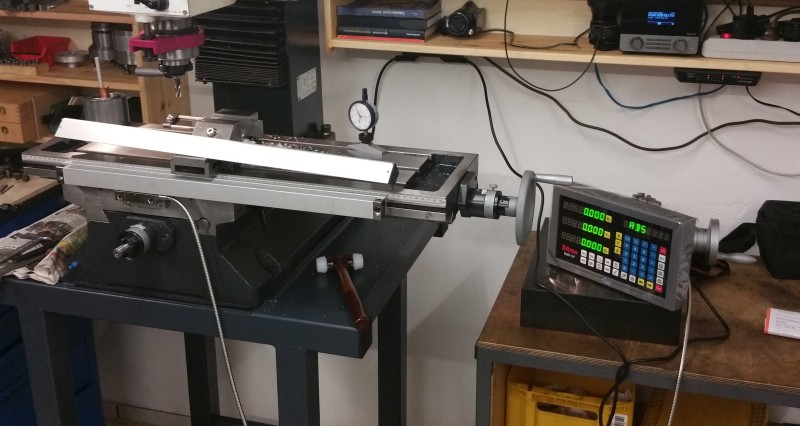

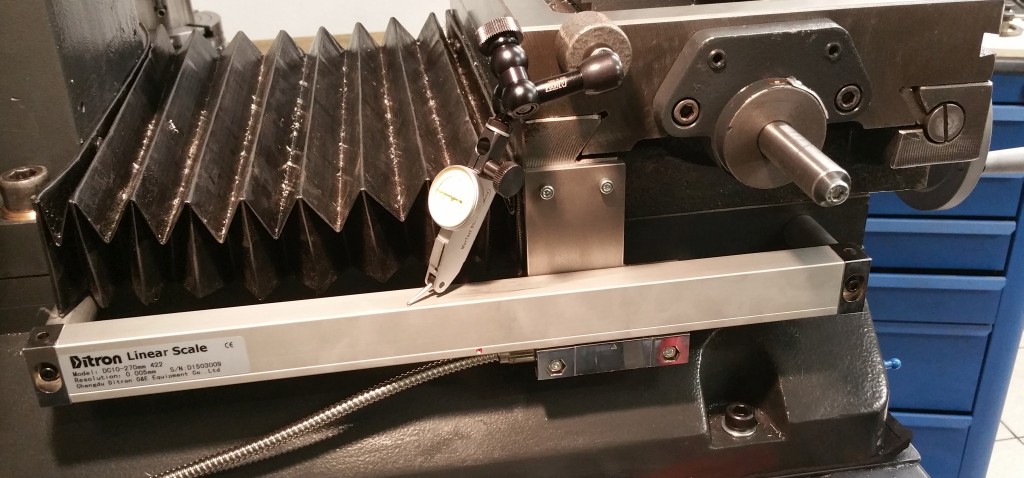

The DRO and the scales are branded "Ditron" and come from China

I wanted to mount the Z scale to the column and not to the quill, which makes in my mind sense. When doing heavy cuts, you want to move your whole Z-axis and have the quill all the way up in its bore, where it has the most stiffness. I think Machining with a long stickout on the quill is bad practice and increases wear on the machine.

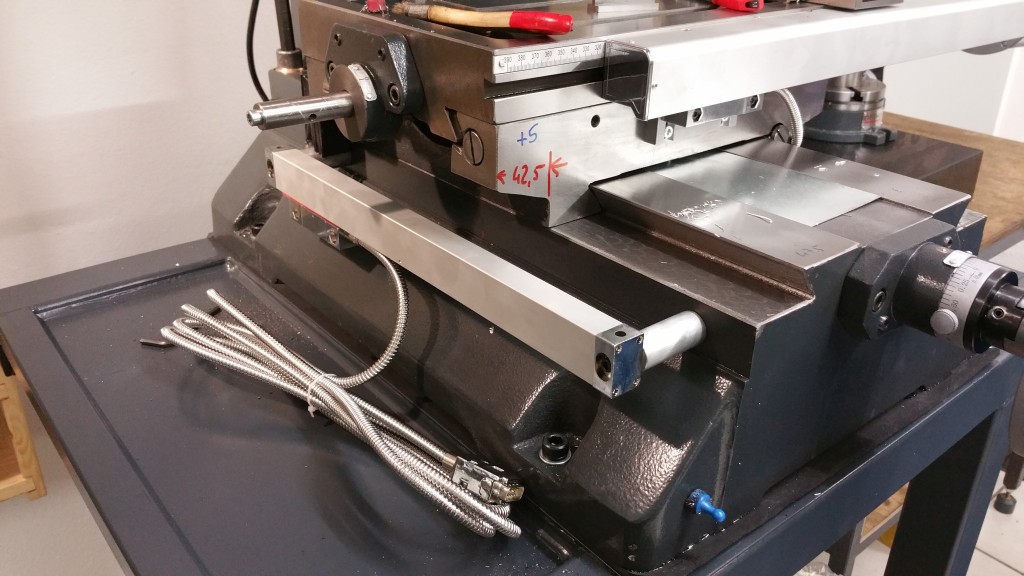

The X-axis is simple, as there is a dovetail slot that can hold the mounting rail for the scale - It just needs to be aligned properly:

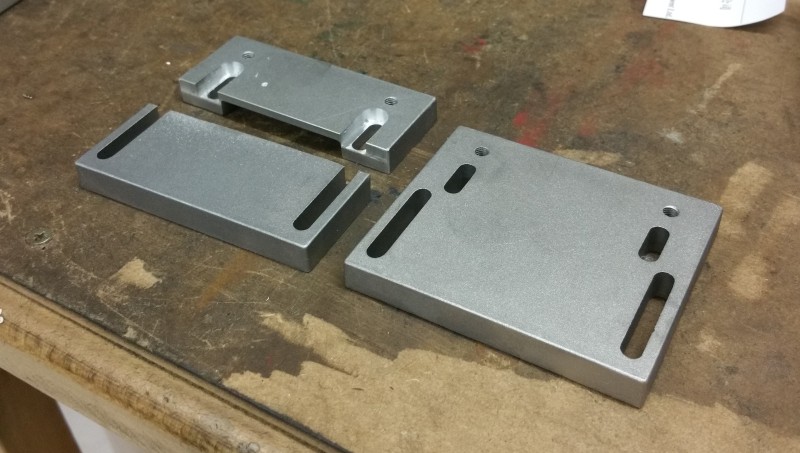

One of the supplied mounting brackets worked for the x-readhead:

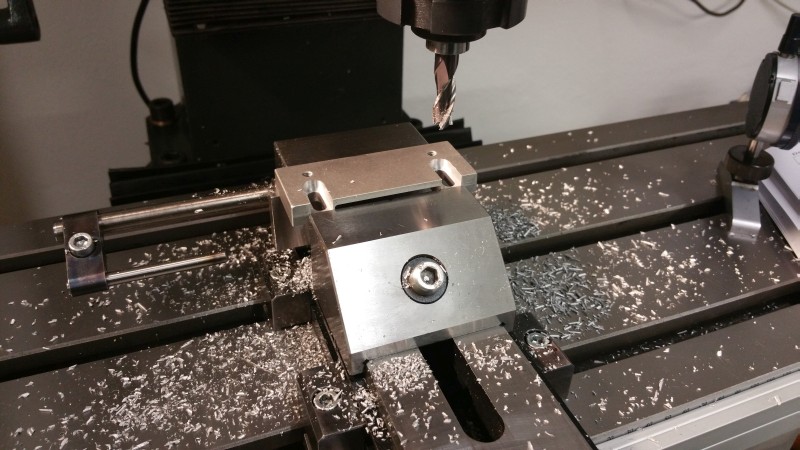

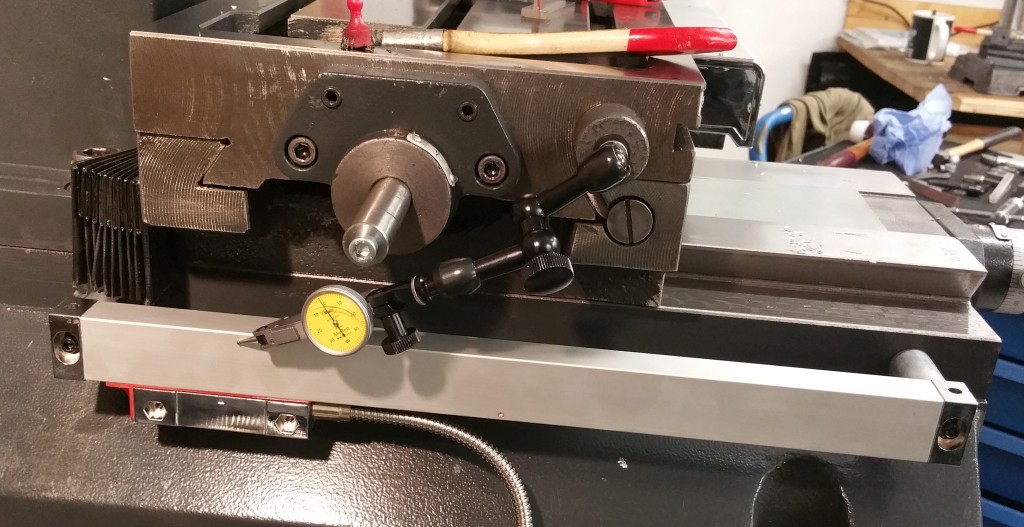

In the Y-axis I had to drill and tap two holes for standoffs, then carefully aligned the glas scale:

A bracket had to be made from scratch to connect the readhead against the crossslide:

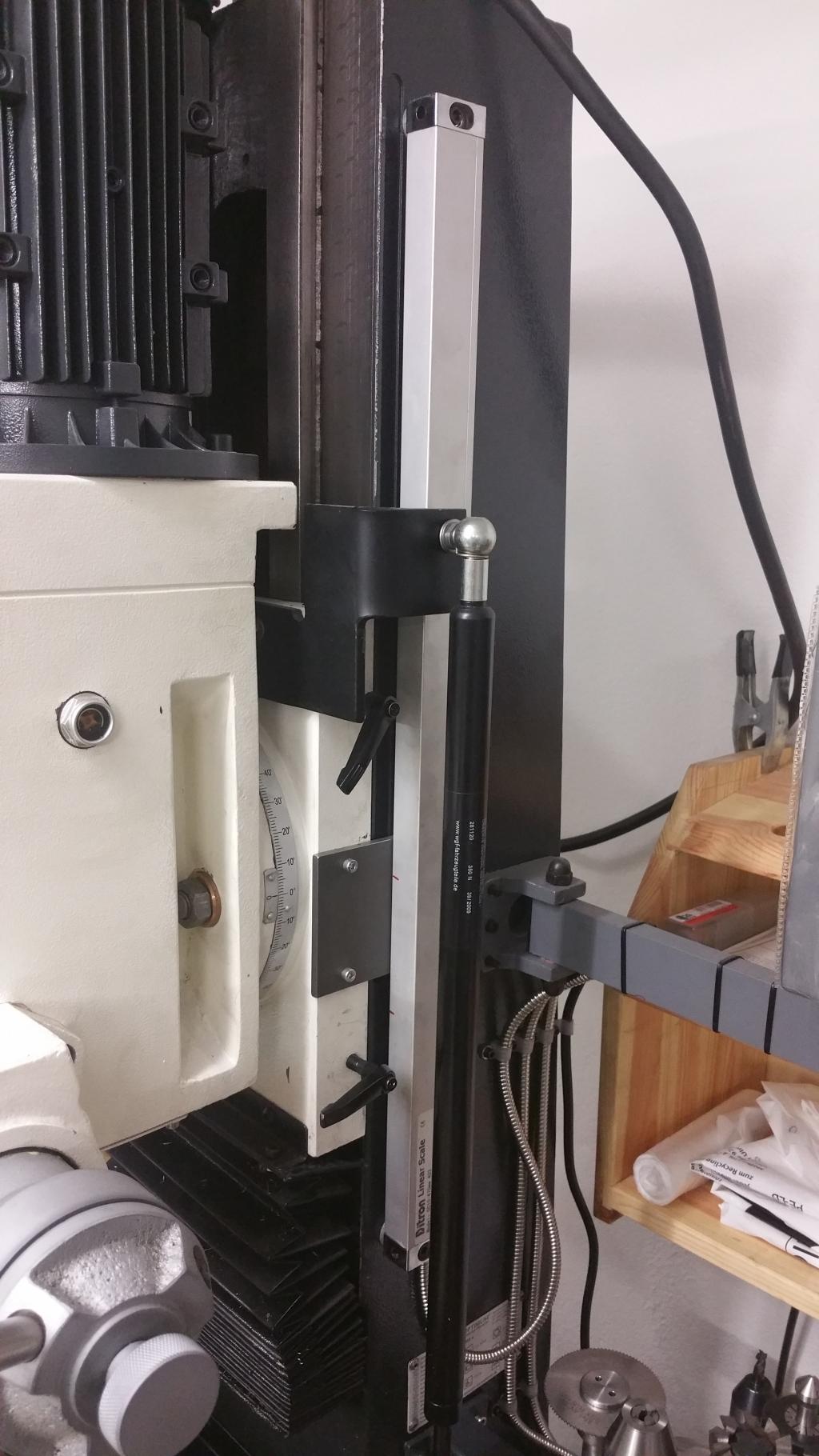

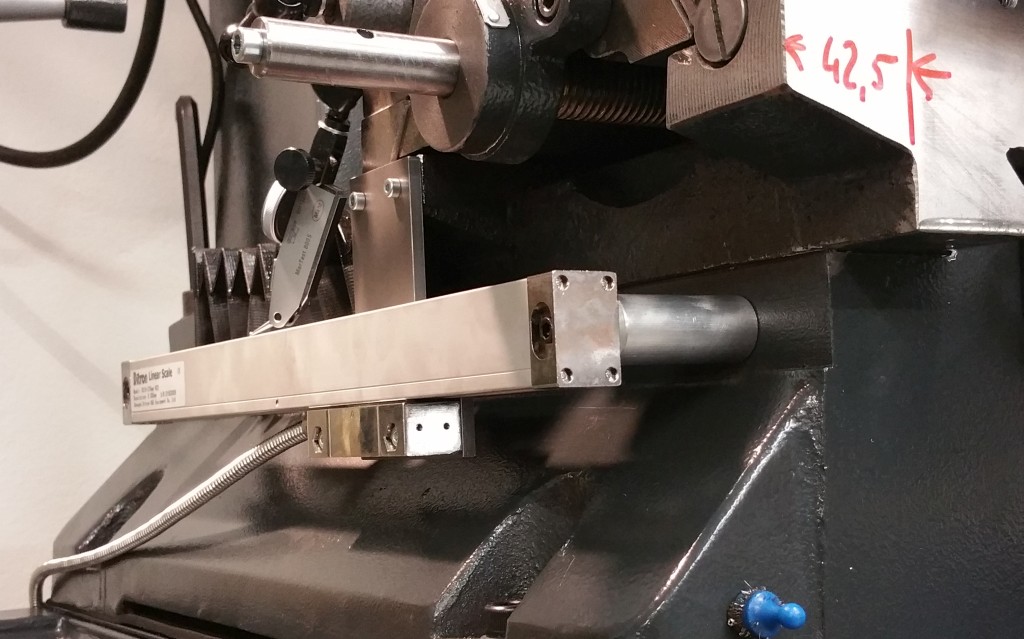

This is the way the scale for the Z-Axis is mounted. There are two spacers with about 5,5mm thickness holding the scale on a defined distance to the column and an adapter plate connects the Z slide to the read head. I went for this design because its a very compact design: