Removing the crate, the machine is bolted to the pallet, at this point I was checking for any major damage, faulty castings, broken parts and stuff like that:

Still on the pallet, I did a very rough check of the geometry, especially the squareness between X and Y - If there was a problem, I would not even start to move the machine down into my basement, it would have gone back to the seller right away - But everything was fine:

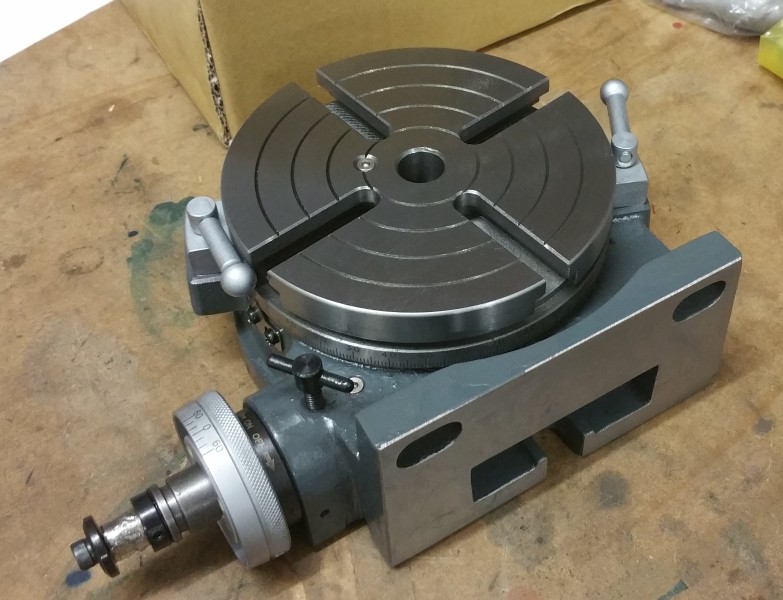

This is the Vertex rotary table I ordered with the machine, 150mm in diameter:

I had to take the machine apart in order to get it down in my shop. First thing was to remove the motor, a three phase 400V motor with two speeds, 1,1kw/1,5kW:

A view of the electrical cabinet, looks not to bad, the components are good quality, the two big contactors are even Siemens branded:

At this time it started to rain quite strong:

To remove the head from the milling machine, I supported it with a piece of wood, loosened the screws and lifted the head off to the side. Sounds easy, but the head, without the motor, still weights about 60kg, not the best idea to do that by yourself without a crane:

Then the column could be removed and trucked down the stairs:

Next thing was the t-slot table, the cross slide and the base, which all where pretty easy to move by a single person:

The head required the help of a second person and a lot of care, not to damage any of the important parts like the quill:

All thats left - A pallet and some plywood:

Typical for a chinese machine, all the parts had at least some form of grinding dust on them. It is a very good idea to clean them before reassembly:

An example of the ammount of dirt I washed off the parts:

Those stupid spring washers where under the heads of the screws that hold down the column. They are completely useless and only good to be trown into the scrap bin. The spring force of such a washer is orders of magnitude lower than the clamping force of the screw, so the washer doesn't do anything usefull:

I machined new, heavy duty bronce washers for the column screws and the t-bolts that hold the head to the vertical slide:

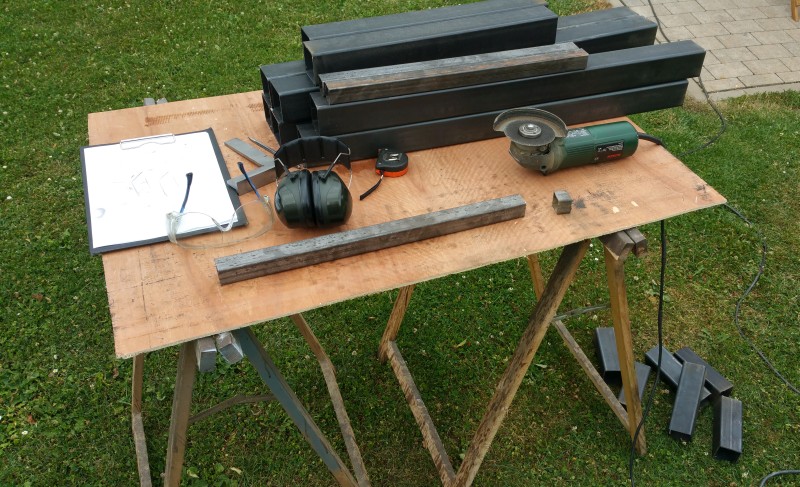

Time to fabricate a table for the milling machine, main material is 60x60x4mm square tubing:

After painting, the base of the machine was bolted to the table, with a layer of rubber between the casting and the sheetmetal cover of the table:

Before assembly, I chased all the threads in every part with old taps to get all dirt out of them:

Slowly getting everything back together:

The head is quite a beast to lift that high without a crane, even with two persons: