Quite some time ago I made this indicator holder which could be chucked in a 6mm collet, a drill chuck or an 6mm endmill holder:

Worked very well, but you had always to change the toolholder to clamp the indicator holder. I decided to make a clamp similar to the Indicol holders as shown in this link:

Indicol universal holder on Amazon.com

Rough layout on 12mm aluminum tooling plate, the print is used as a reference:

Roughed out on the bandsaw – I use a cheap woodworking bandsaw with a 18TPI blade for aluminum sheet/plate:

I started to bore the center hole with the boring head slightly bigger than the spindle nose of my milling machine:

Machining the straight sections of the outer contour:

machined away most of the material inside the bore, leaving only two pads that will contat the spindle nose. That gives together with the clamping screw good nice three point contact:

Machining some clearance for the clamping screw with the brass pad:

I did not cut a thread into the alumium part, I just drilled and reamed a 6mm hole – A steel bushing with a M4 thread will be loctited in later. I do this becaus I dont like threads, that are used for clamping, in aluminum:

Deburring on the engraving machine using a guide pin:

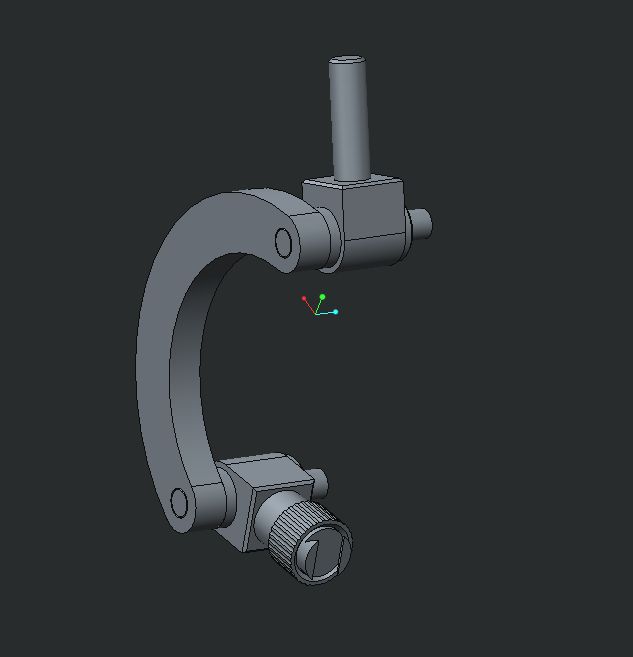

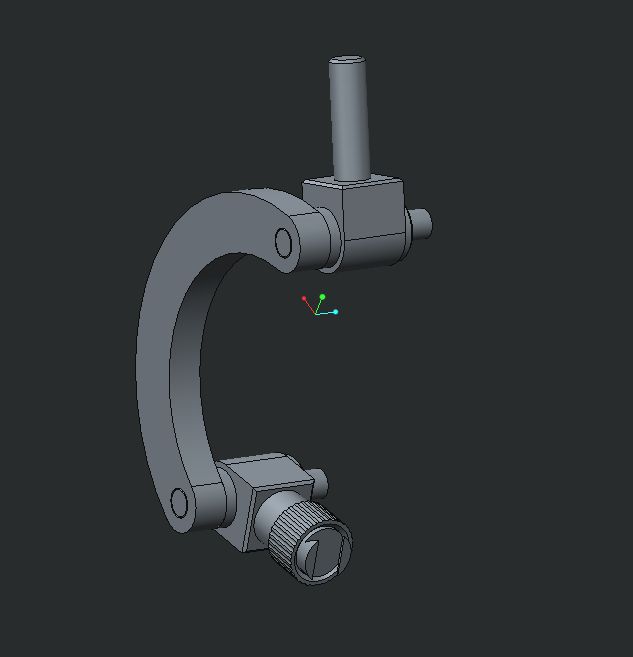

Finished clamp with the turned parts:

The clamp with the indicator holder:

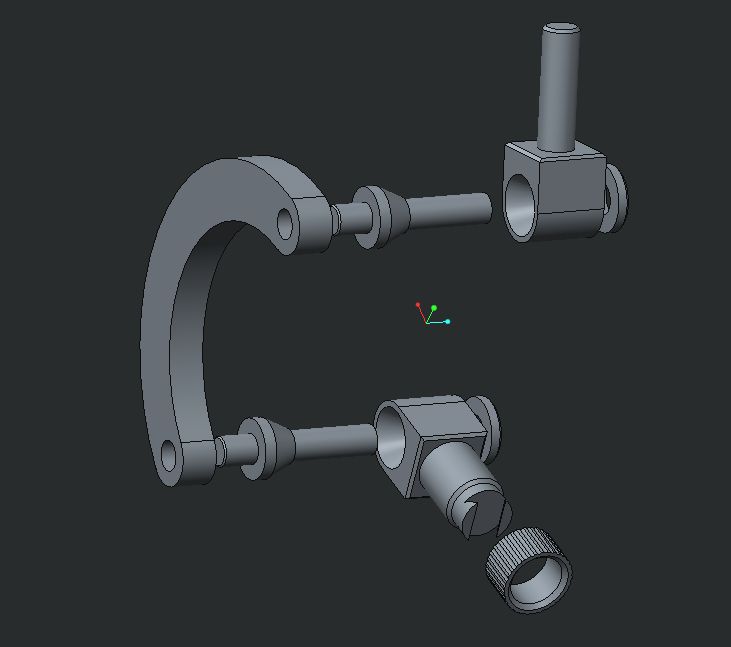

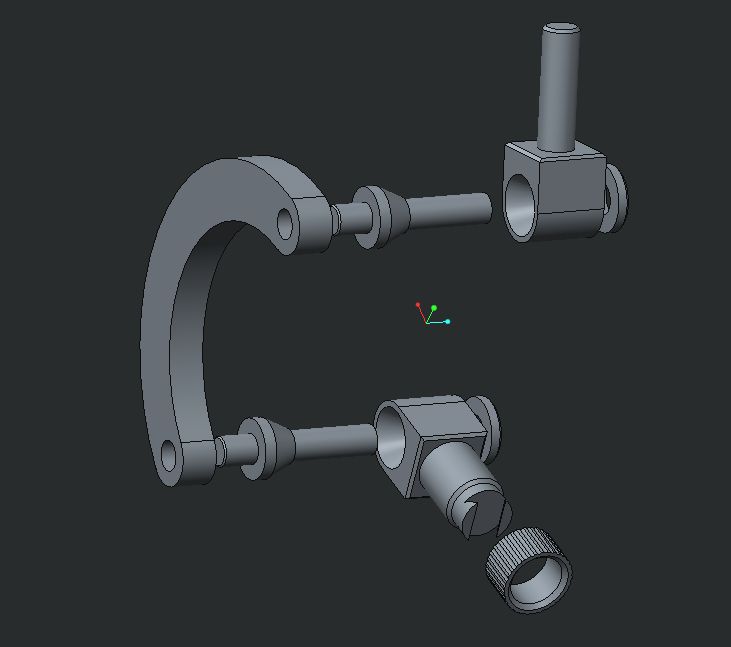

Parts of the clamping mechanism:

Fits the spindle nose of the machine very well: