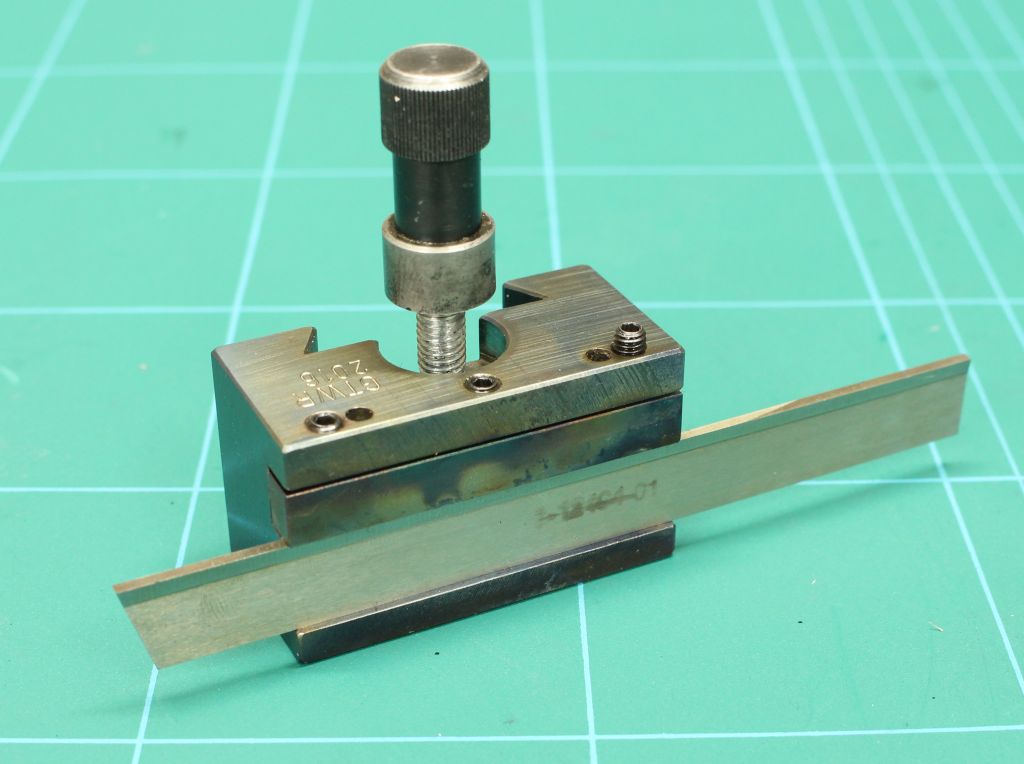

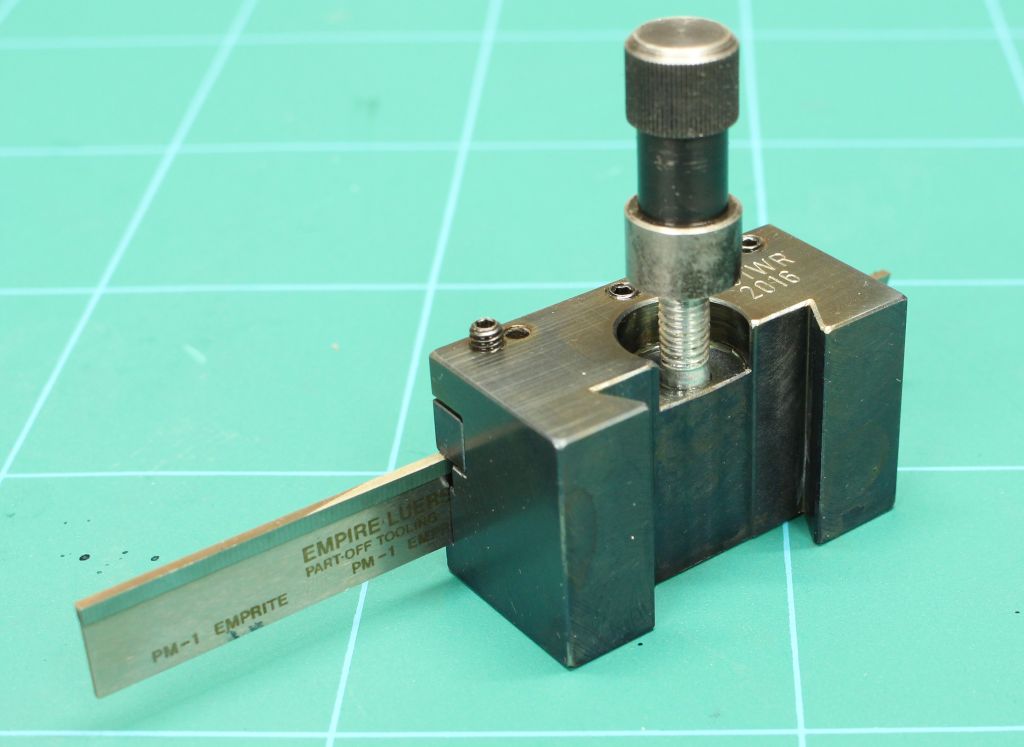

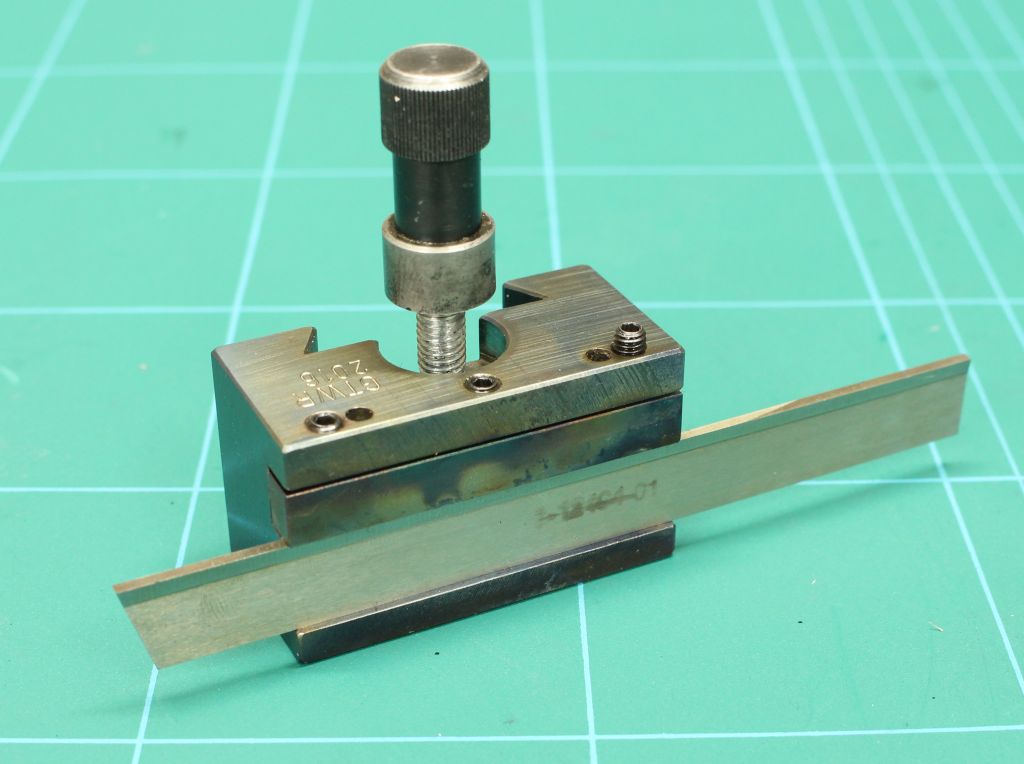

I got a few t-shaped parting blades, 1.6mm wide, and a short search on the internet showed that this is a pretty common style of parting blade.

The whole system is called “Churchill”.

At first I wanted to build a holder for the blades that could be clamped in a QCTP holder, but after doing a few sketches it got obvious that it would not work that way – To much overhang.

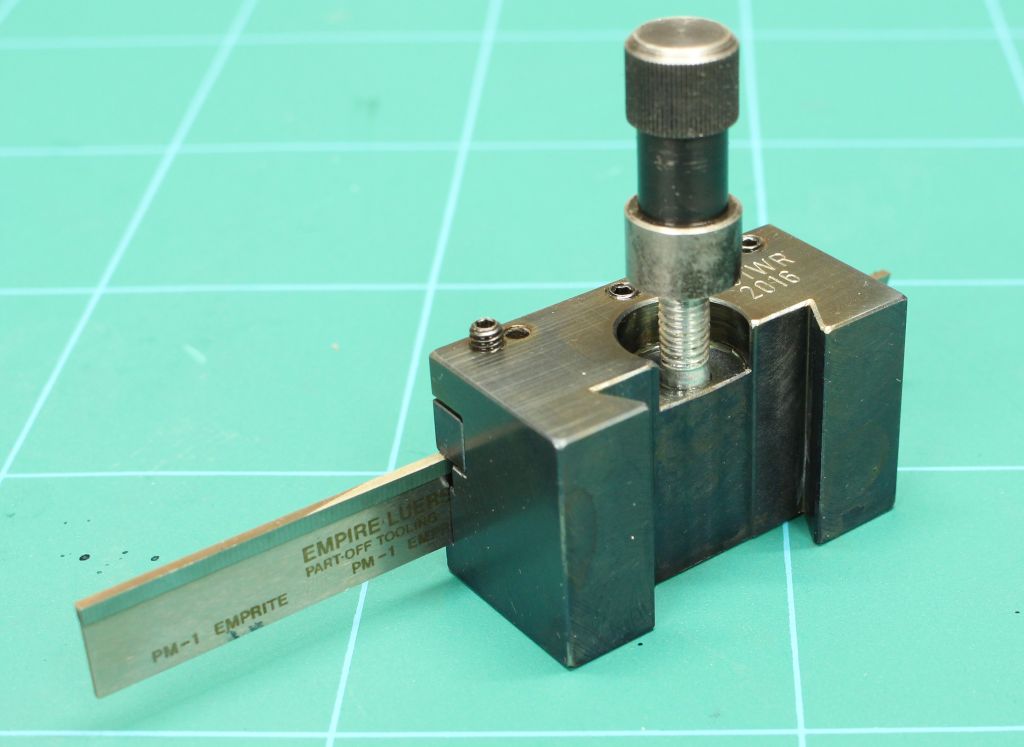

I decided to make a complete new Tripan holder specialy designed to hold the parting blade:

Material is carbon steel (0.45% carbon, unhardened). The clamping gib that holds the blade in position is held in position with two dowel pins and clamped with the three setscrews on top.

With blades of that style its important that the blade is lined up with the travel of the cross slide, as they don’t have a relief ground to the back

On the other hand its not super critical as the blade is only 1.6mm thick, so it follows the cut if there is a light misalignment.

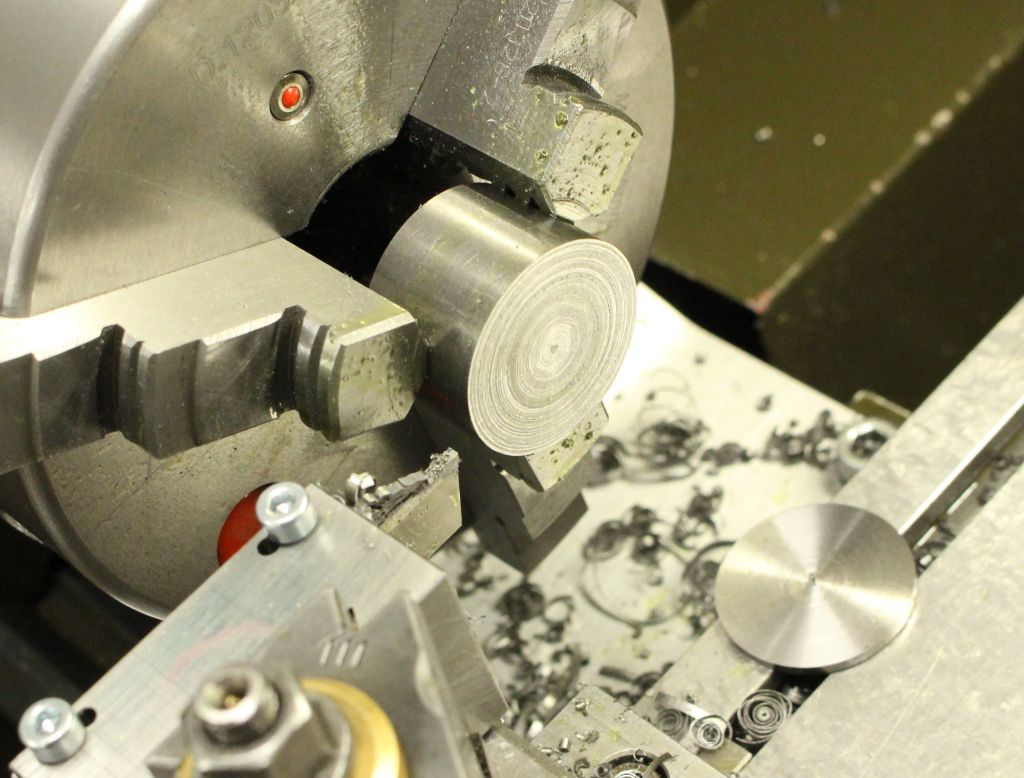

I did a testcut in 30mm fee cutting steel: