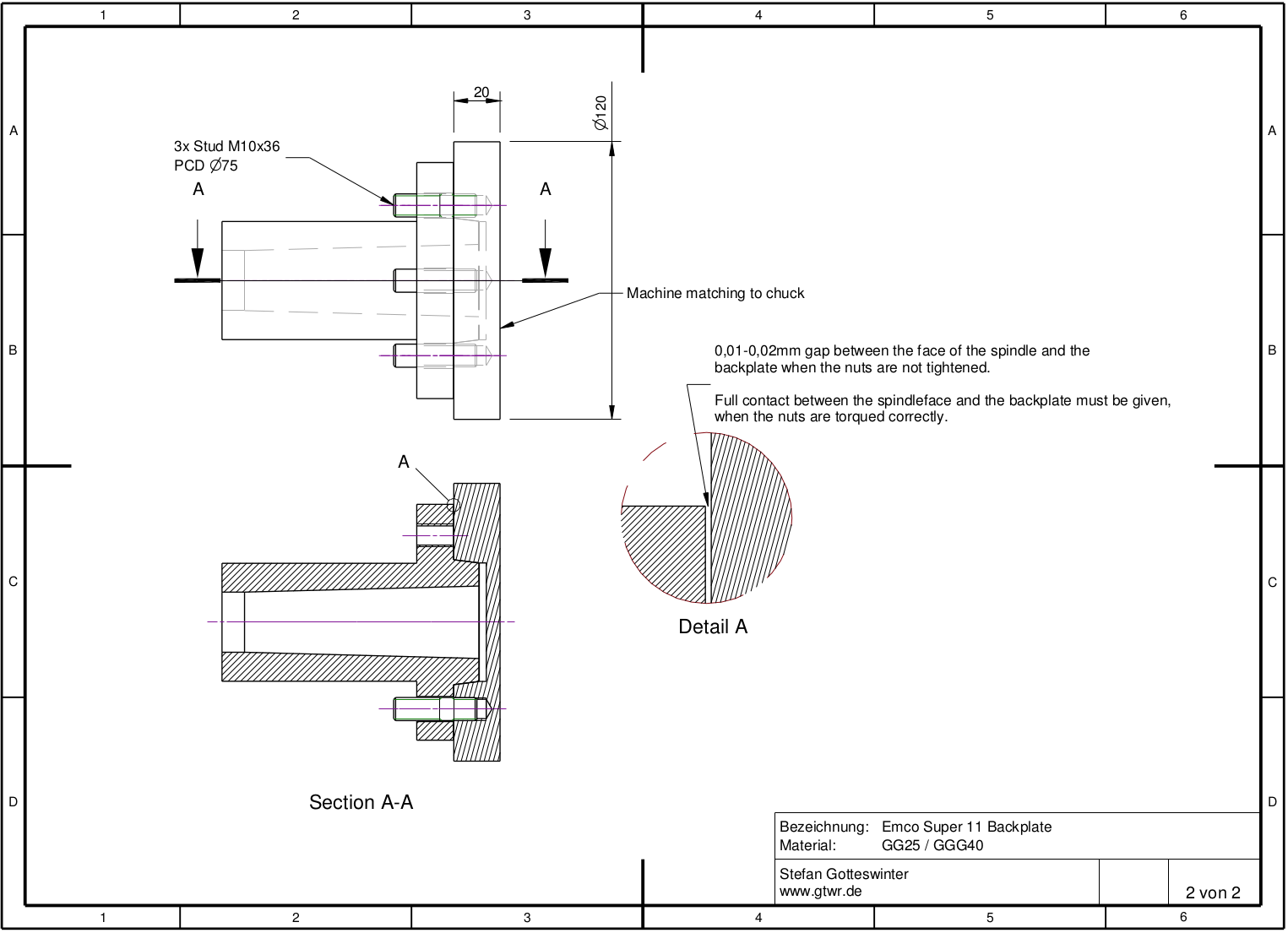

The Emco has a shorttaper Nr.3 spindle (Thats the same taper as a camlock D1-3, just without the camlock feature), the chucks get bolted to the spindle.

This pfd file shows the dimensions of the spindle nose and a design for a backplate, along with some notes:

Emco Super 11 Spindle

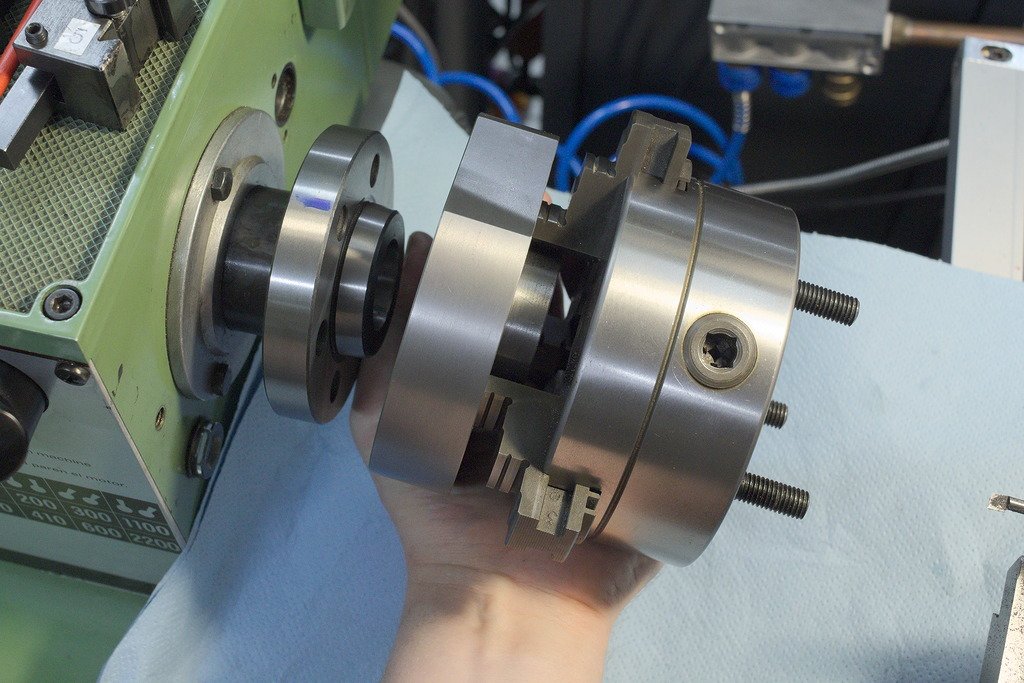

My old lathe had a very similar spindlenose, just with a cylindrical centering boss - Luckily smaller than the taper on my new lathe, so I was able to bore the backplates out to match the new machine.

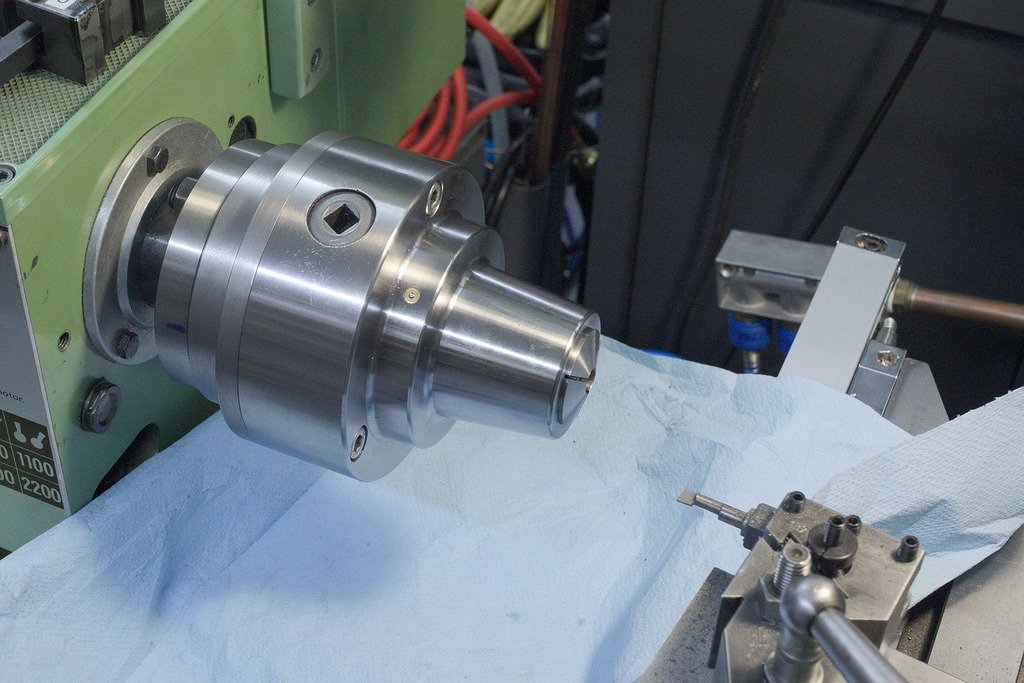

Here I am boring out the backplate for the sixjaw chuck - The backplate is held in the original Emco threejaw and adjusted as good as possible for radial and axial runout.

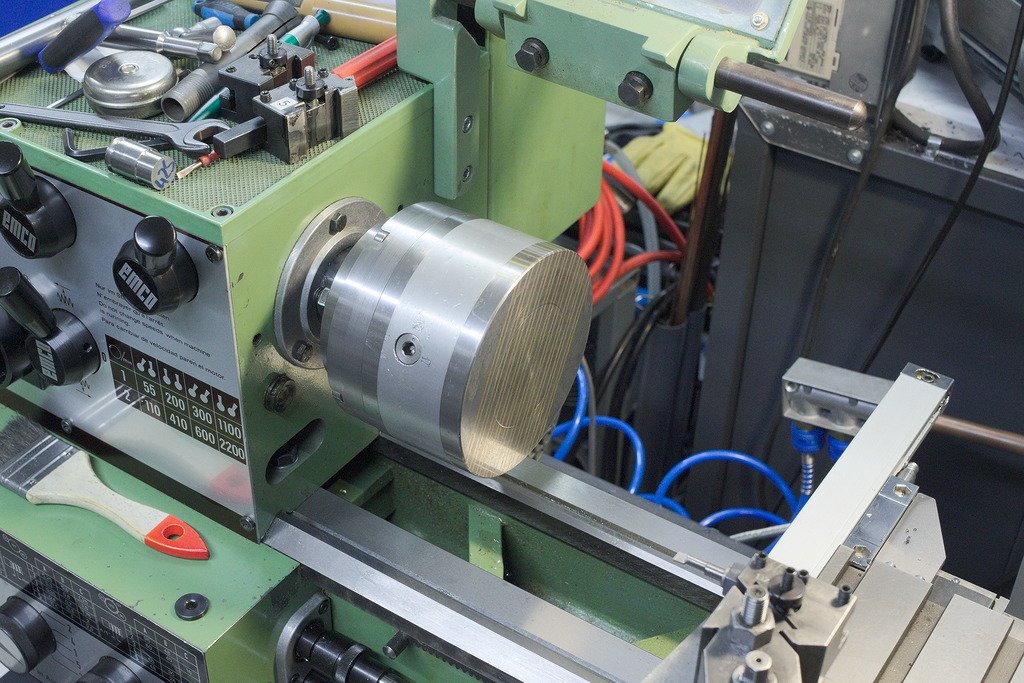

Checking the backplate against the spindlenose by keeping it in the threejaw chuck and removing it all together from the spindle to check it. That way it can be mounted back for adjustments without loss of precision.

On a properly machined shorttaper backplate, there should be (depending on the size) a small gap between the spindle and the backplate (in case of this spindle, about 0,01..0,02mm) when put together with handforce, no screw torque applied.

The other two important chucks are the 5C collet chuck and the magnetic chuck: