The shaper I got for my shop is a Gack HE20 toolroom shaper. The HE stands for "Hobel, einfache Ausführung" (Shaper, simple version). Simple as there is also a version with a universal table that can be tilted (Thats the Gack H20), which is especially usefull when used in punch/die work . The simple version has just a rigid table. The "20" stands for 20cm (200mm) stroke.

A video showing the shaper in detail:

Gack HE20 toolroom shaper

More detailed articles on different aspects and modifications on the machine:

Examples of work

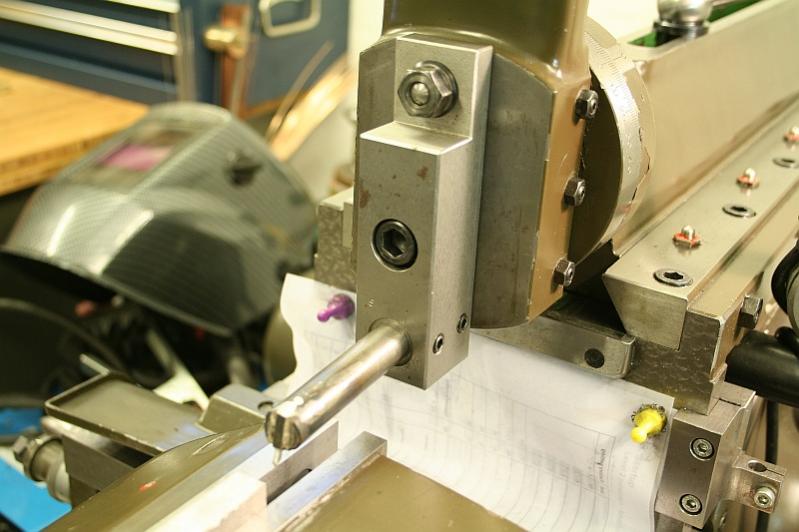

Cutting a gear rack:

Machining castings - One is the table of a drill press, the other one is the main casting for a small dividing head:

Cutting keyways is a important role for the machine in my shop - Especially as I don't have a press and broaches.

A fairly long blind keyway - It has a relief hole drilled at the end, to give the tool some clearance:

The tool for the keyway shown before. It is a piece of mild steel with a HSS blank silver soldered into the end and then ground to shape: