Our specialty is the manufacturing of miniature components and assemblies with complex geometry, tight tolerances and a high demand for surface finish.

Special Attention is taken when it comes to edge treatment, demurring, surface finish and cleanliness.

Inspection of dimensions is done via a wide range of tactile measuring instruments, we also have access to an high precision measuring microscope.

If needed, we will design and build custom gages or test fixtures for your project.

|

|

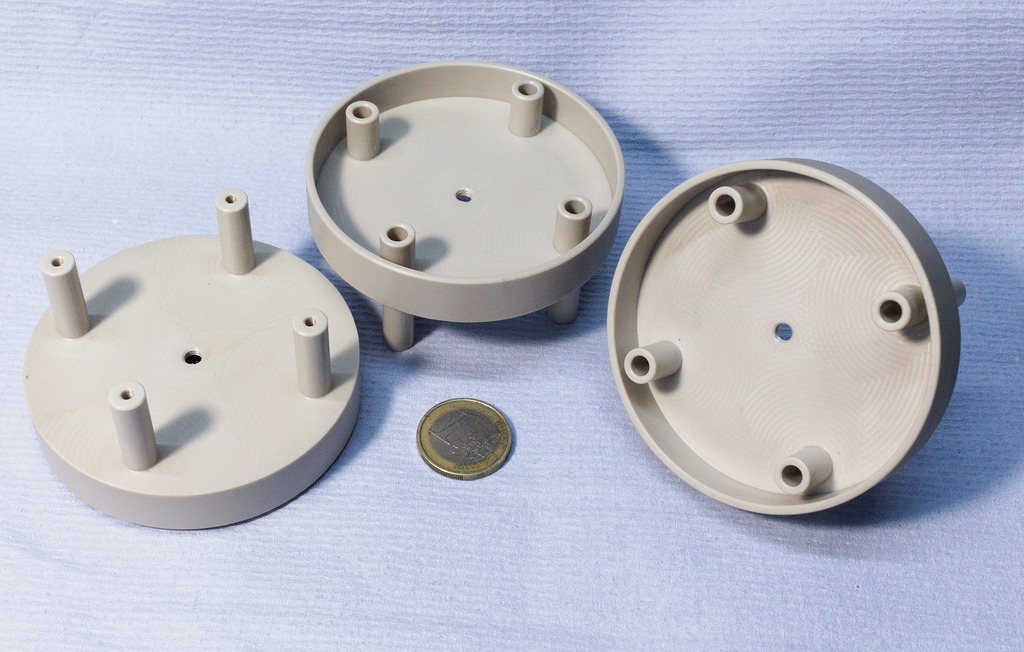

| We reverse engineered and manufactured these lamp holders for a Kern Theodolite | The part was designed in CAD with the aid of a damaged original part |

Capabilities

Turning: Starting at diameter 1mm

Drilling: Micro drilling starting at 0.3mm

Milling: Smallest endmill diameter 0.3mm / Thinnest saw blade 0.2mm

We have access to a number of grinders for making or modifying tools and tooling for special operations.

|

|

|

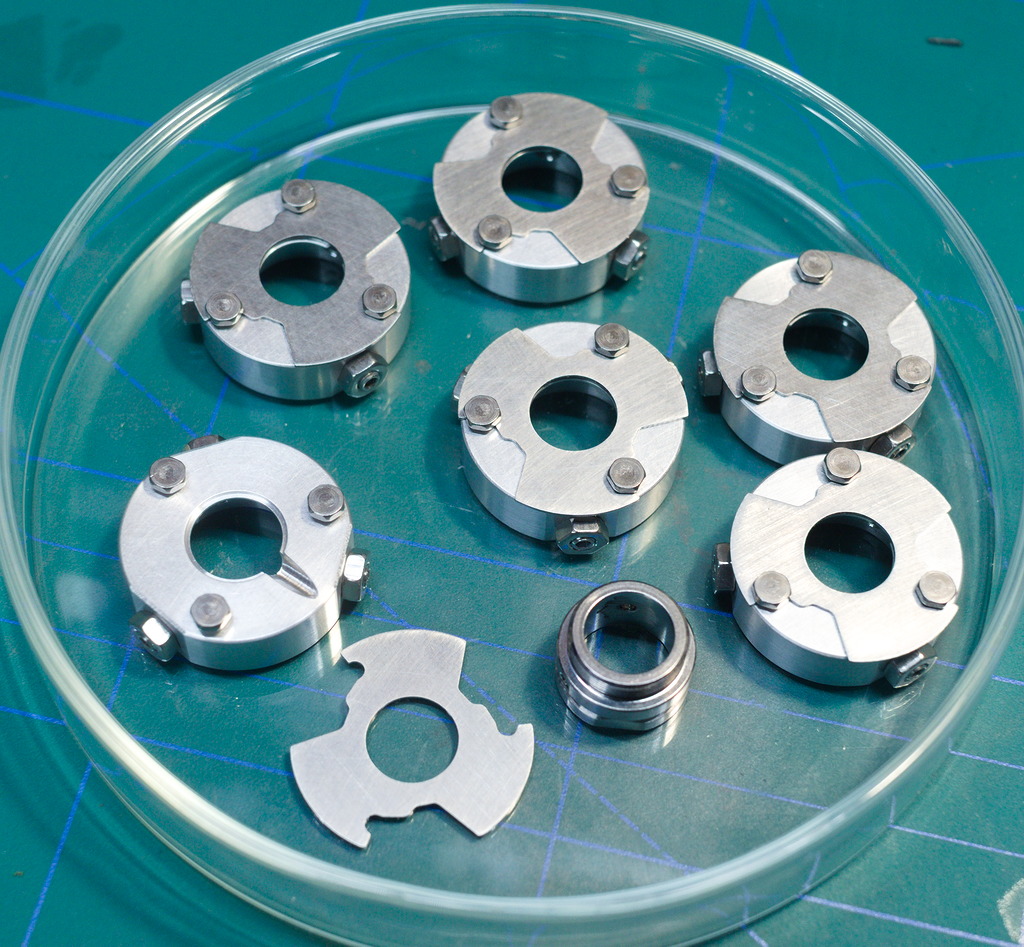

| Covers, machined from PEEK | Vent screws - Machined from titanium, Torx Tx8 drive, thread M4x0.35 | Housings for Collimator optics, machined from stainless 1.4305 |

Furthermore we have wide experience in prototyping parts that will later become stamped and formed sheet metal parts in production..

Equipment

CNC machines

HSC milling machine (30000rpm, 320x300mm working envelope)

Laser engraver (100x100mm working envelope)

Manual machines

Deckel Fp1 milling machine (300x150mm working envelope)

Weiler Primus lathe (240mm maximum turning diameter)

Bema FSM260 surface grinder (260x100mm working envelope)

Excessive accessories and support equipment

Metrology

TesaHite400 height gage

Nikon MM-40 measuring microscope with Quadracheck readout

Wolpert hardness tester

Wide array of handheld measuring equipment and gages