Centering and locating features on either a CNC or manual milling machine is a very important step. The industry provides us with a wonderful selection of tools for this purpose, edge finders, mechanical 3d probes all the way up to electronic probes that talk to the CNC controller.

There are tools and techniques beyond of the here shown, like centering microscopes that let you pick features visually, the very oldschool wiggler or even a simple dowel pin in a collet.

But the ones here shown are the more common that I have to say something about.

Edge Finder

The simple edge finder is a tool that I like very much – It is very affordable and reliable yet delivering a high degree of precision when picking up workpiece edges.

The design of the tool does not necessitate perfect runout, the work just as well, when you put them into a drill chuck.

Mechanical 3d Probe

The least favorite Solution for me is the mechanical 3d probe – They have a surprising high actuation force that is not equal in all directions, they are highly depending on their runout being set correct, they need a dedicated toolholder (That’s more a nuisance on a manual mill than on a cnc) and are overall not very confidence instilling to me.

These types of probes also require a fair amount of clearance between the spindle and the work.

Dial test indicator

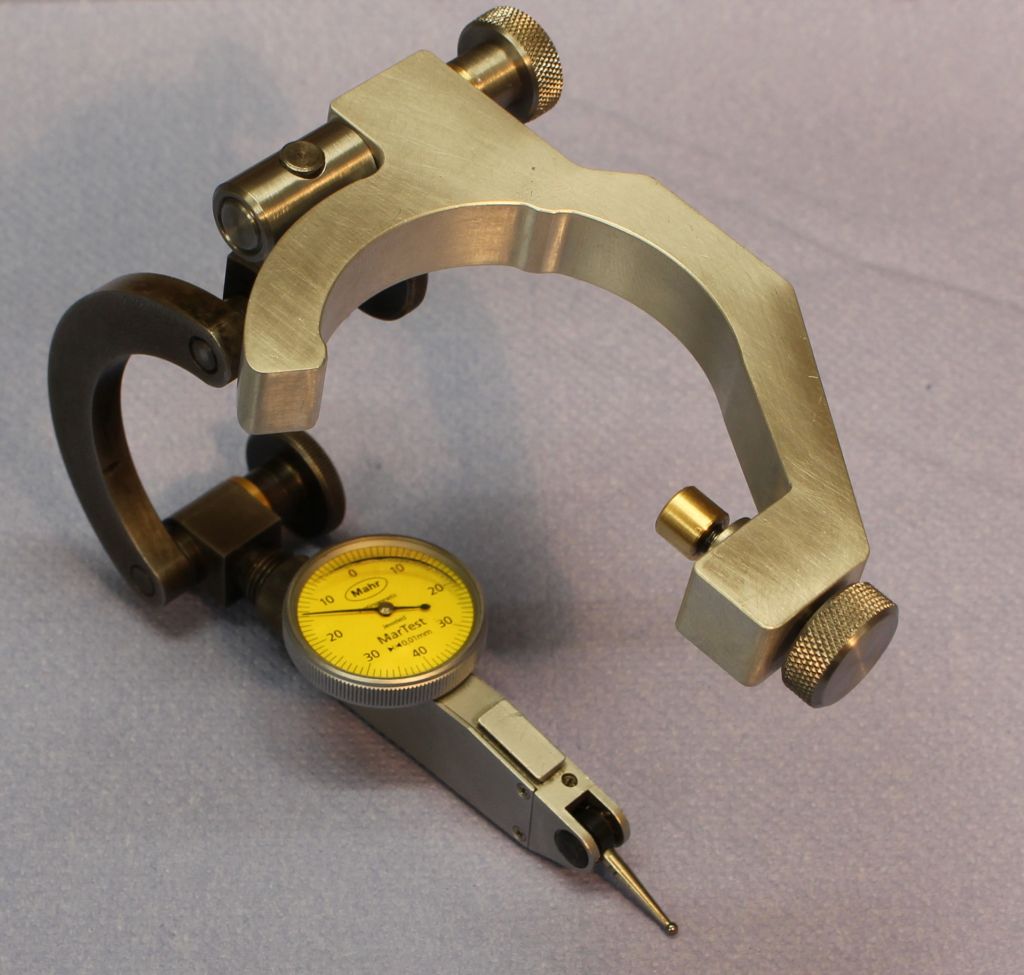

My favorite solution is a dial test indicator that is in some way mounted to the spindle of the machine and has some adjustability built into it.

This can either be a flexible arm – like what is used on a magnetic indicator stand – Held in the spindle or clamped to the spindle/toolholder.

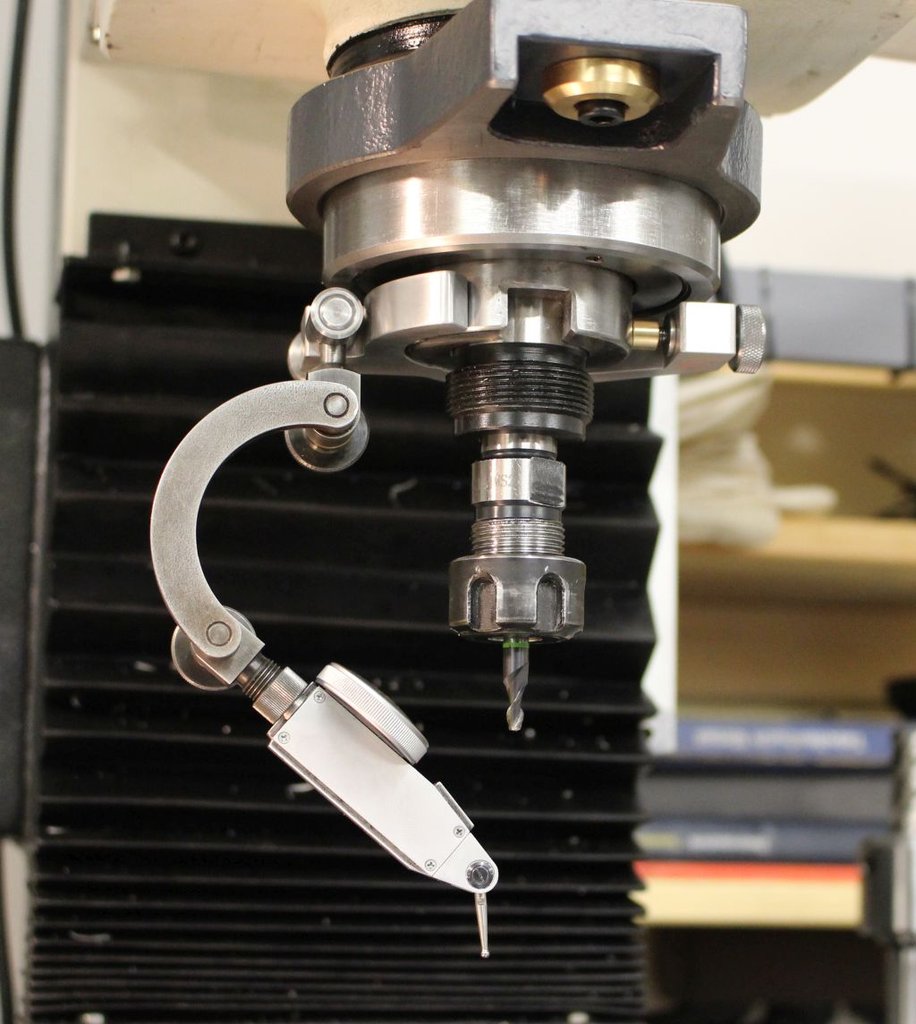

This is an example of a flex arm mount that is clamped to the ER25 collet nut of a high-speed spindle.

Holding them in a drill/collet chuck is also an option:

These holders give a great range of freedom, but that’s also a drawback, since its quite time consuming to align the probe tip in a meaningful way.

Personally, I prefer a holder that has less freedom of motion, like the very popular halfmoon shaped holders that can also be held in a toolholder or clamped to the spindle/toolholder with an additional clamp.

These can either be purchased commercially or make for a neat little shop project. The one shown here was built in-house, a set of drawings for the half-moon holder is available in the files section.

Held on a milling machine spindle vs. held directly in a collet:

For certain types of machines, like CNC routers height clearance is a real concern – None of the commercial options are very satisfying in that regard. That’s why I came up with the following design that’s extremely low profile and has the necessary adjustability to line the stylus up with the center of rotation built into it.

The set of drawings for this holder can be found in the Files section of this blog.