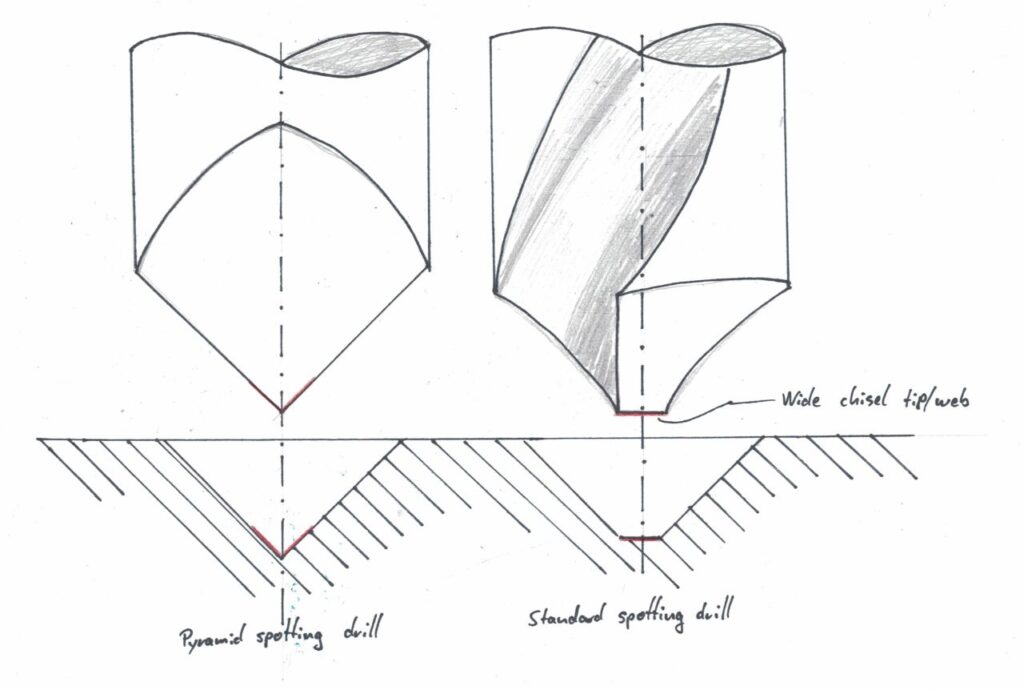

Spotting and centering small drills is not a trivial task. Normal NC spotting drills have a wide web and tend to create a spot with a flat bottom that’s unsuitable to guide small drills.

There are specialized one or two flute carbide spotting drills for small diameter work, but they tend to be rather expensive and extremely delicate.

One alternative that I was made aware of is the pyramid spotting drill – This shape is referenced in literature a few times, not only as a spotting drill, but also as a micro engraving tool for hard materials.

Trying to visualize the problem with the chisel tip/web of standard spotting drills – They leave quite a large flat spot, that might already be too big to guide small drills.

How big is that flat spot left by the web? I am glad you asked.

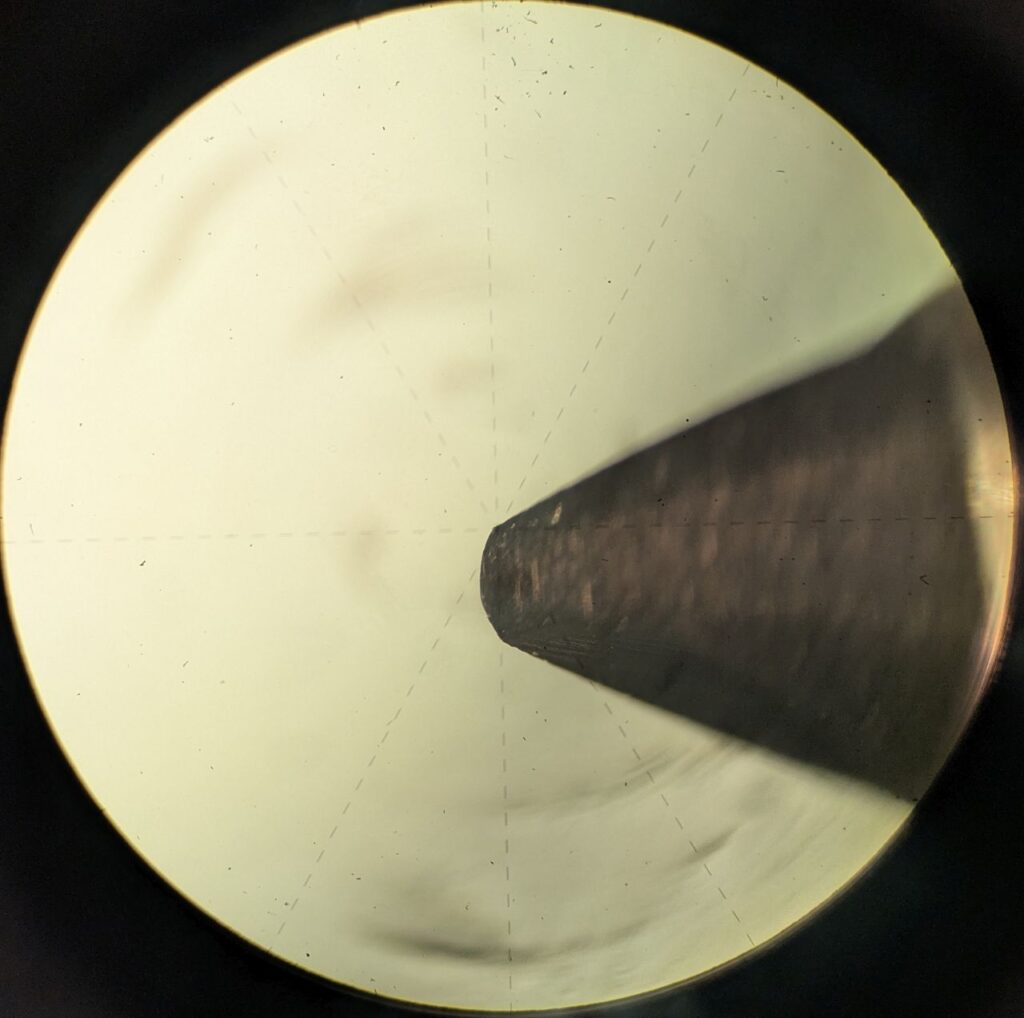

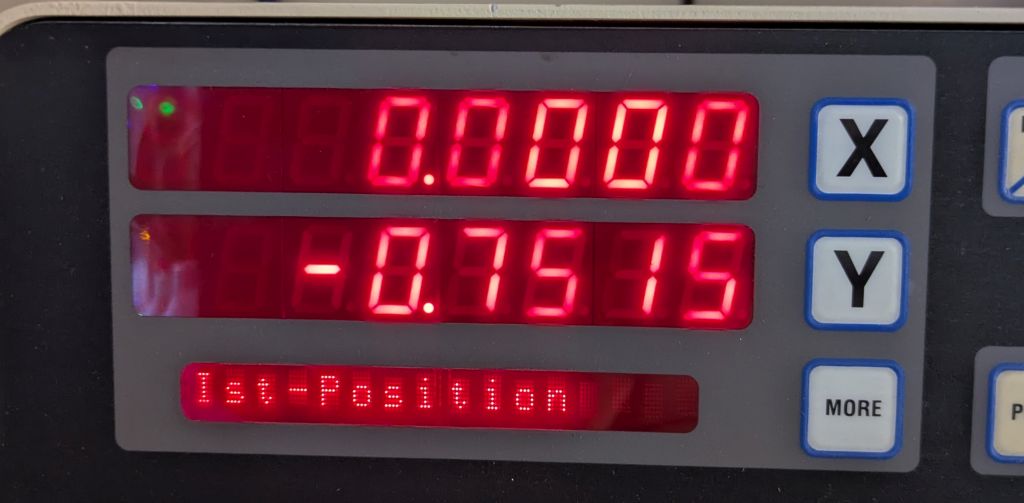

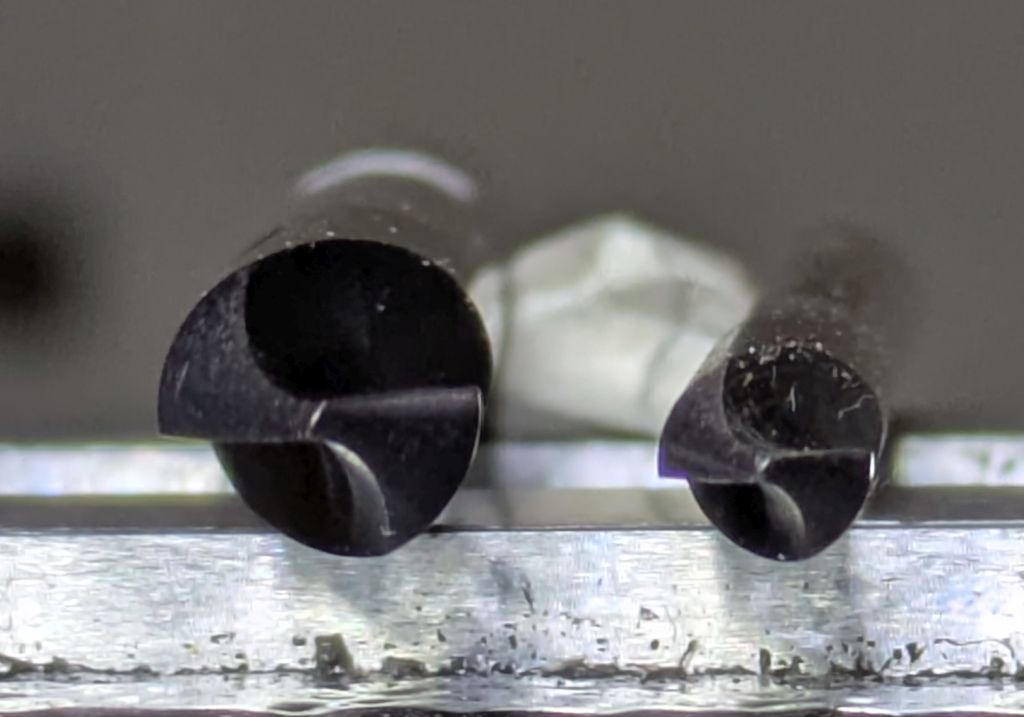

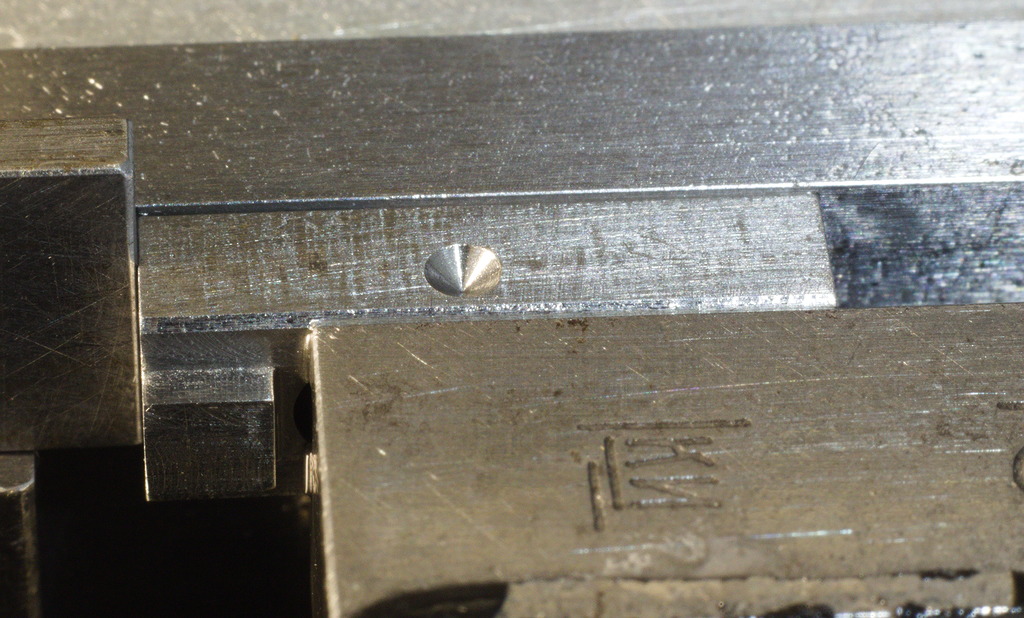

On a good quality 6mm 90° spotting drill I measured a web width of 0,75mm:

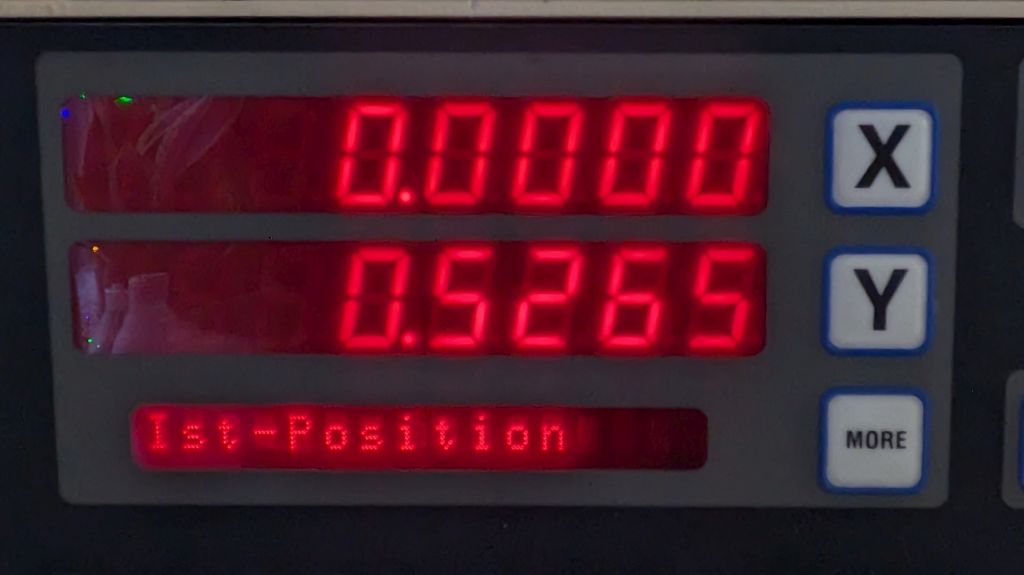

A similar 3mm 90° spotting drill still had a 0,52mm wide web:

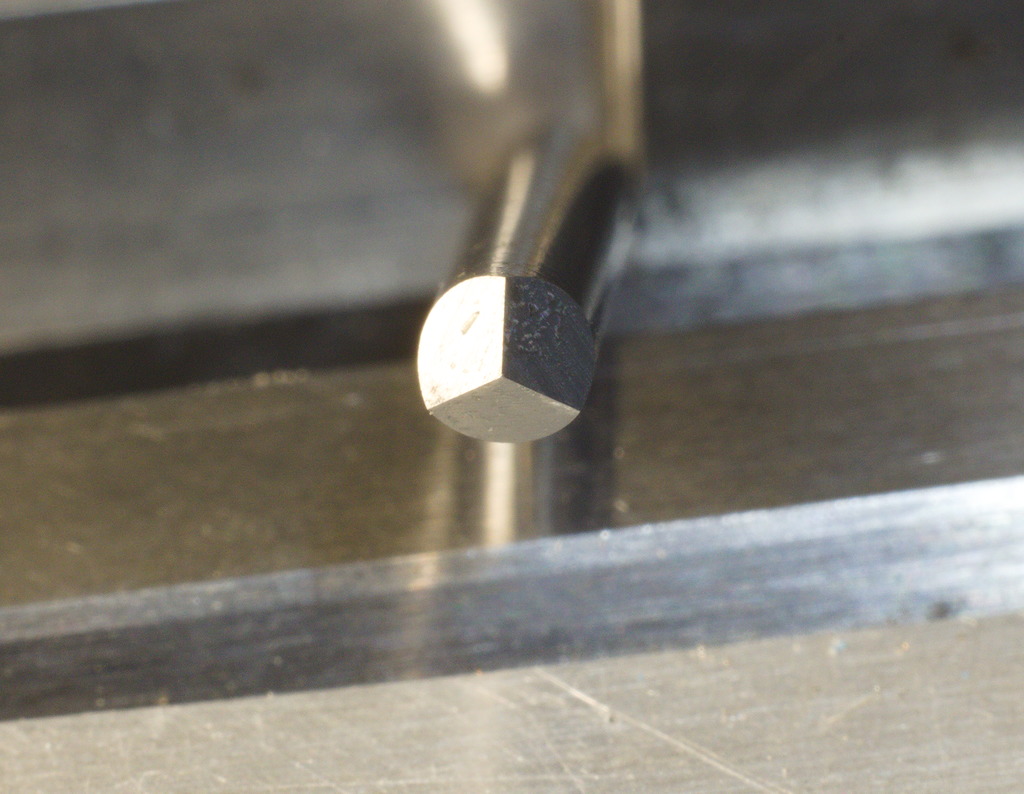

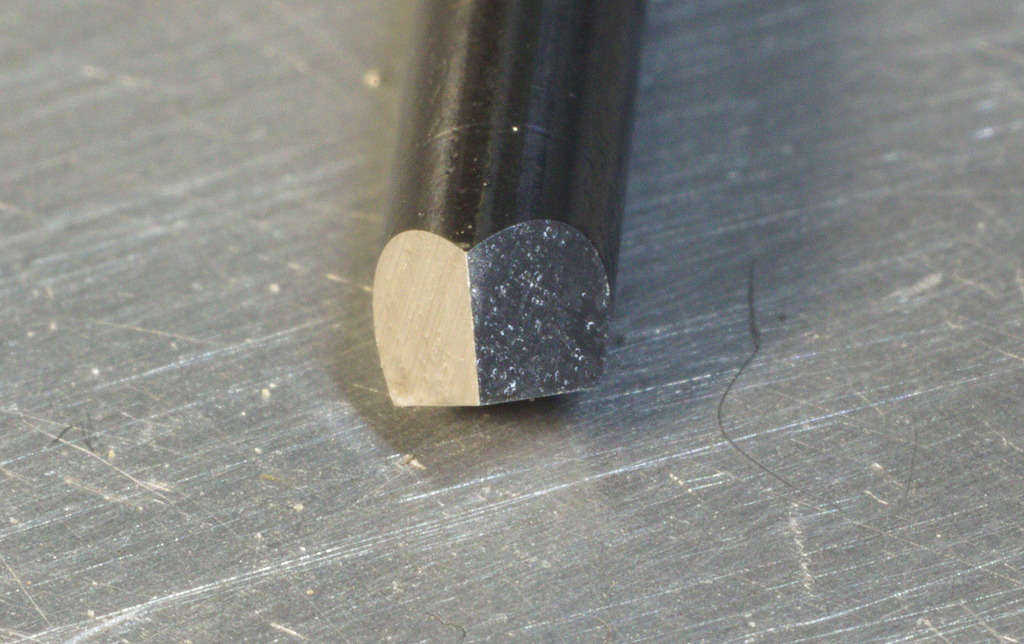

The two spotting drills measured:

You can clearly see the wide web of the drill in the second picture.

As mentioned, there are spotting drills with thinned webs or single flute versions that have almost no web but are extremely vulnerable to damage and wear, so I try to avoid them.

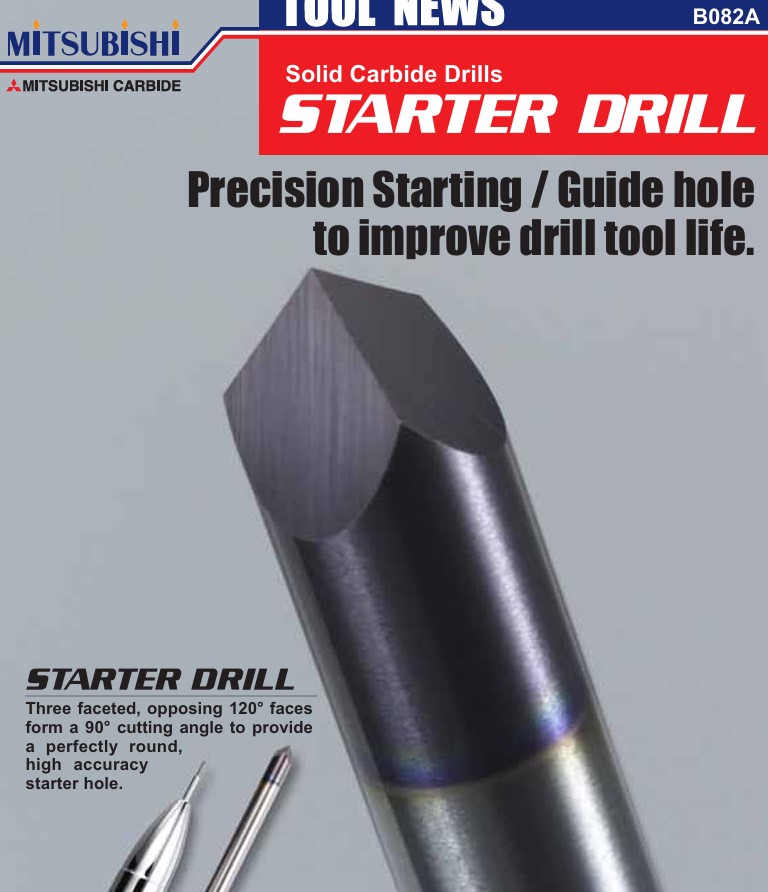

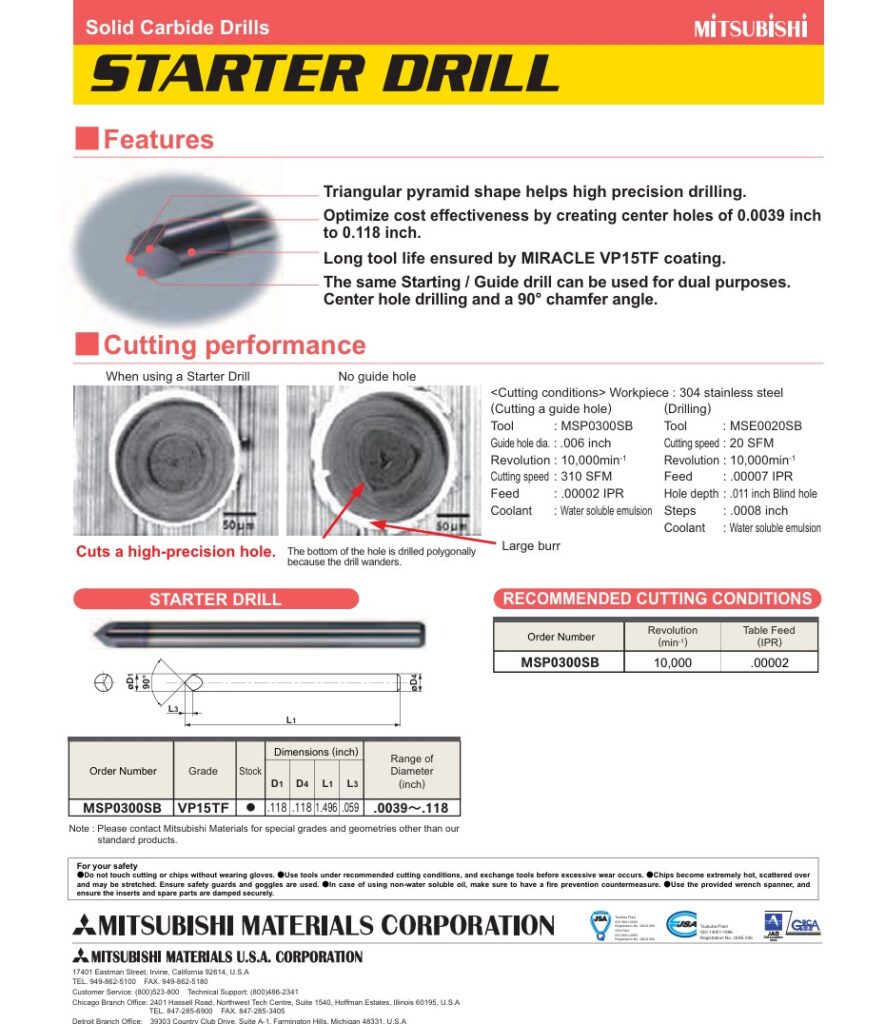

The pyramid spotting drill is available as a commercial tool by Mitsubishi, in a nice, coated version.

https://www.mitsubishicarbide.net/mhg/de/drilling/10000516/20077520

It also comes with a technical datasheet that points out the advantages of this shape and recommendations for speeds and feeds.

For commercial use, I would absolutely recommend purchasing these drills and not bother grinding them in-house.

But, as hobbyists or operating a small shop, it can be an option to grind them out of carbide stock – The shape is very simple and forgiving. All that’s needed for grinding is a way of indexing the blank in 120° increments and some sort of grinder.

A D-Bit grinder, surface grinder with spin fixture, a milling machine with a dividing head or a real tool and cutter grinder will all do a similar nice job.

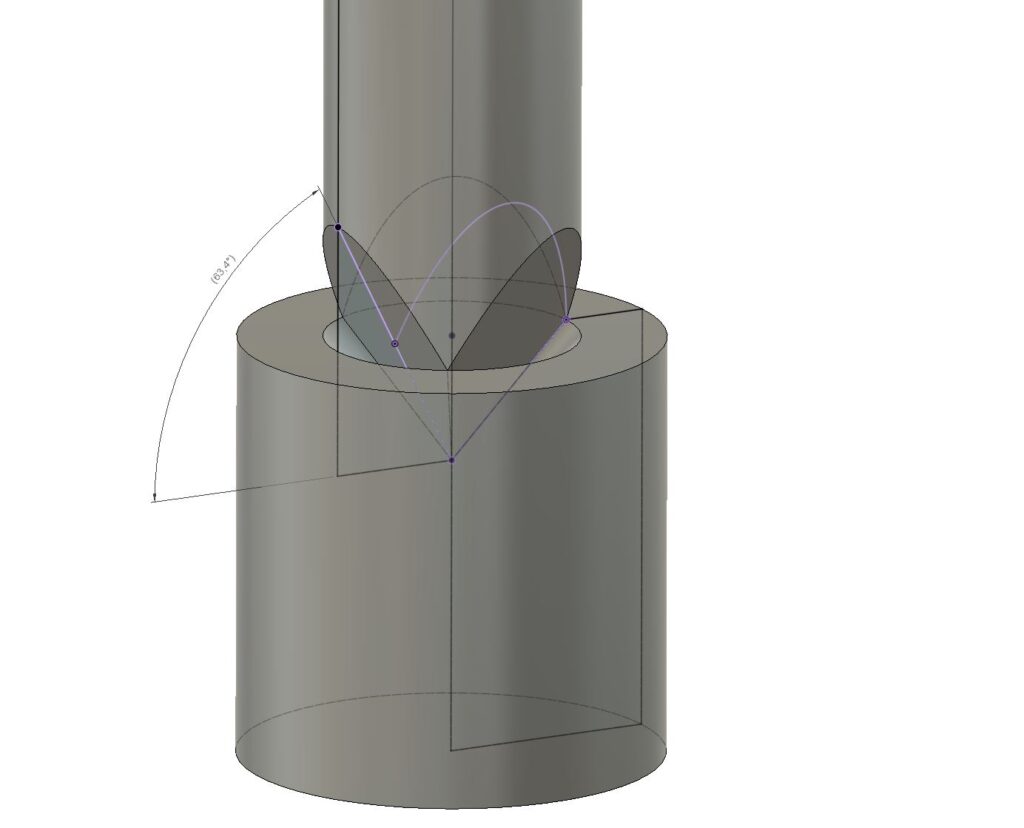

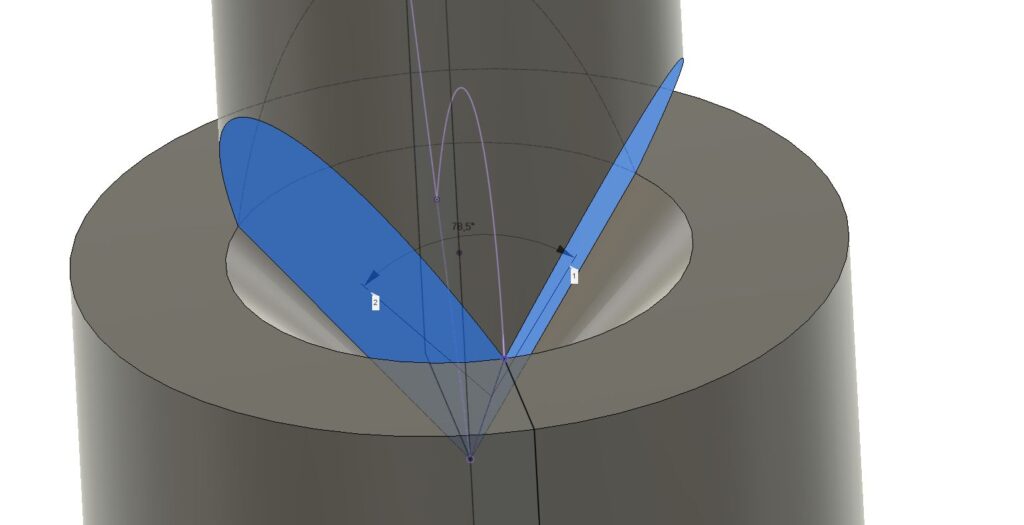

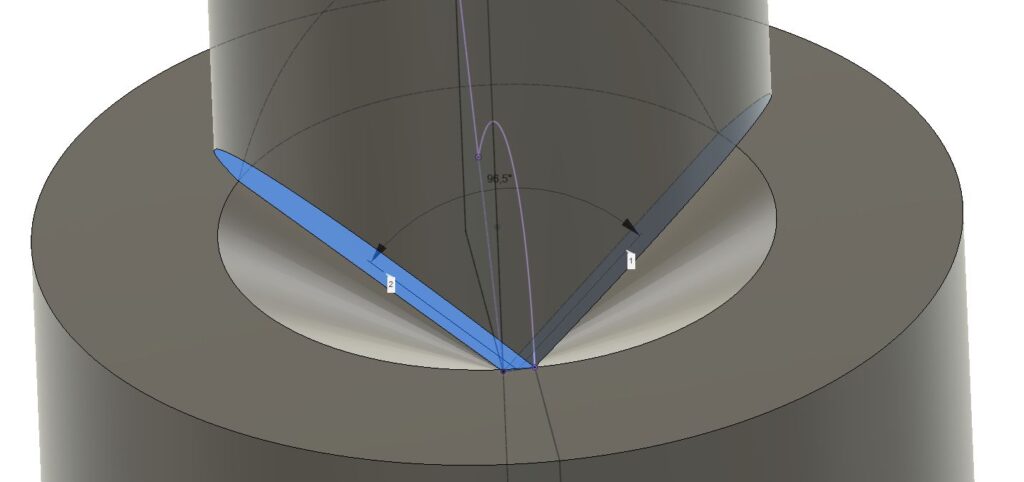

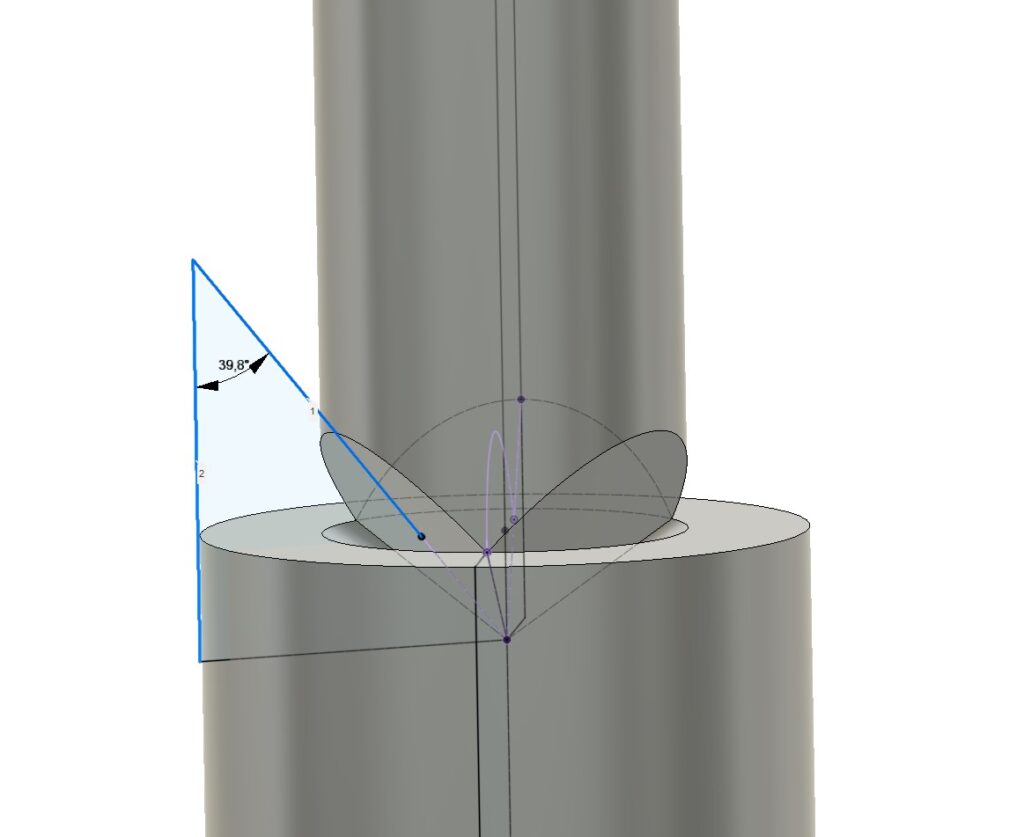

The angle the facets need to be ground can be determined in CAD – This example shows a setup for a 90° spotting angle – The Angle off the facets must be 63.4°

The following example has been ground on a Deckel S1 T&C grinder out of 3mm carbide stock aka the shanks of good quality endmills.

This very simple tool creates amazing, clean and round spot drills. The three cutting edges have a very negative cutting angle and are very robust, no matter what common material is machined.

Interestingly it works very badly when used dry, without any cutting fluid.

What I found works best is a small amount of cutting oil for steel/stainless steel/hardened steels and red metals like copper.

Used with oil it has a very nice and soft cutting action, creating fine, needle like chips:

When cutting aluminum, alcohol can be used as a cutting fluid, with the advantage of flashing off and leaving clean, dry workpieces.

Examples of Cutting:

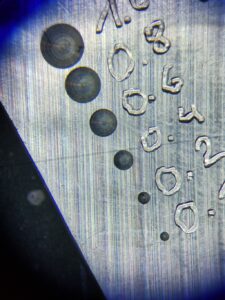

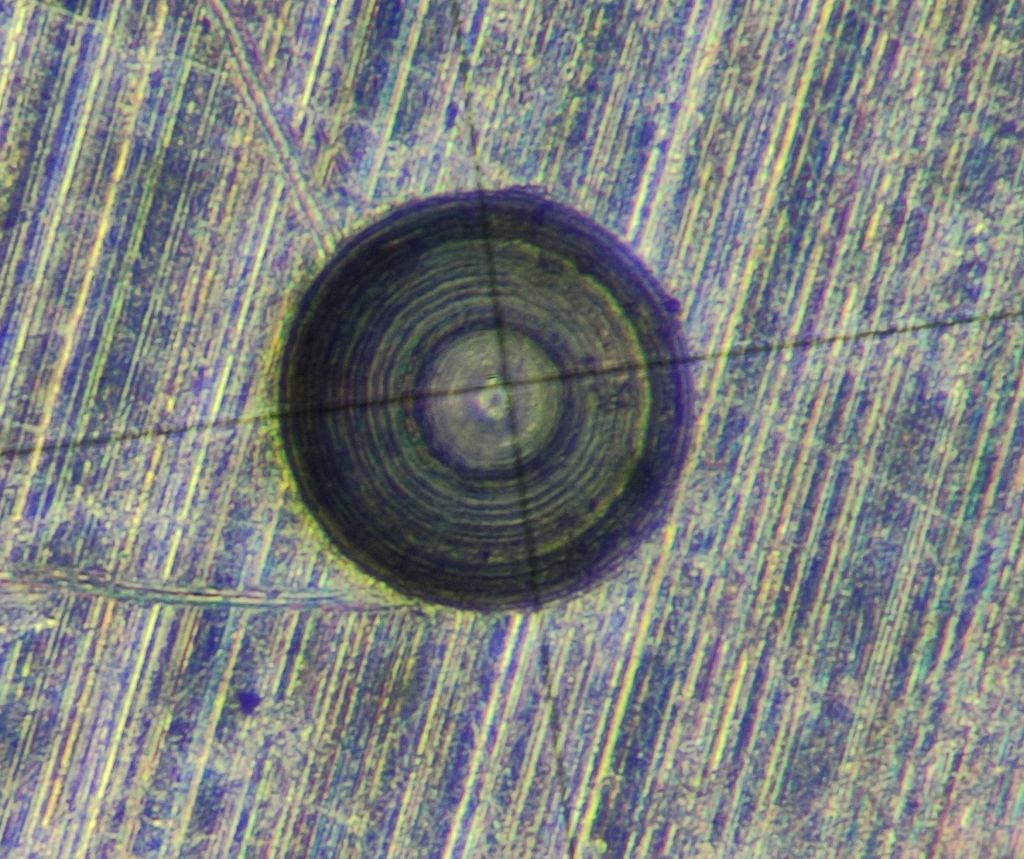

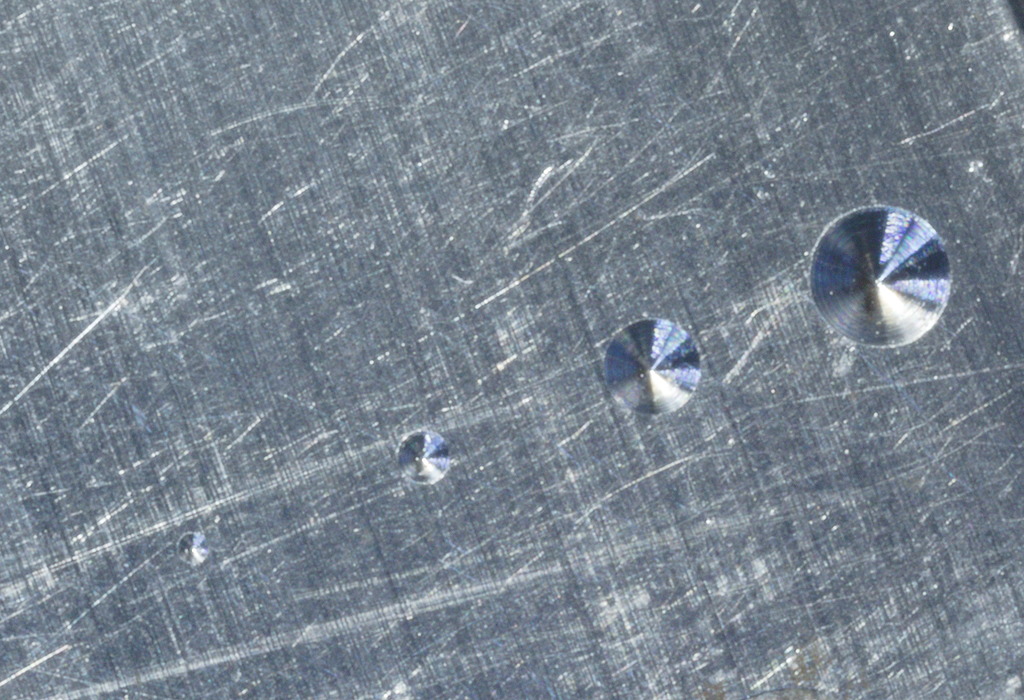

Spotting in aluminium AW5083 – The engraved numbers next to the spot drills represent the diameter of the spot:

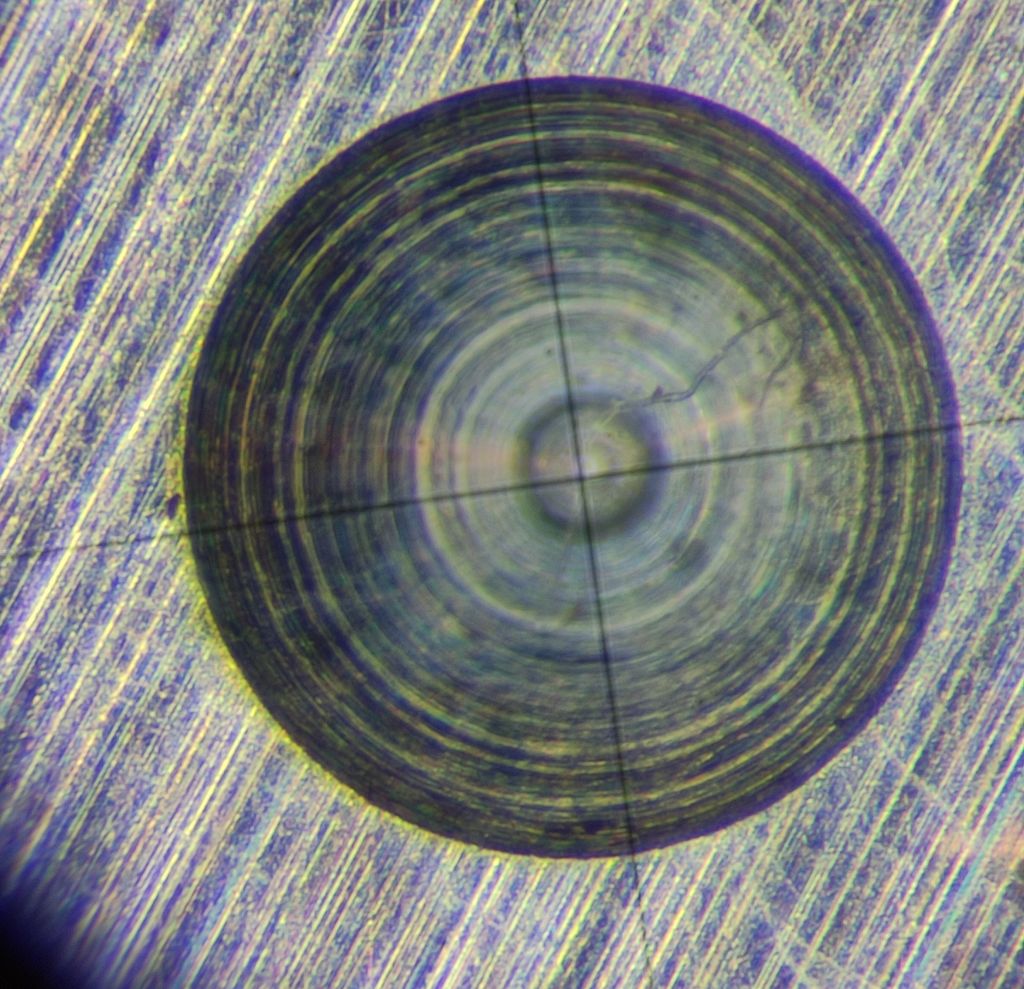

Magnified view:

0,4 / 0,2 / 0,1mm spotting diameter, left to right.

Since the drill is ground to a very small tip (As small as the grinding wheel and the grain size of the carbide allows)

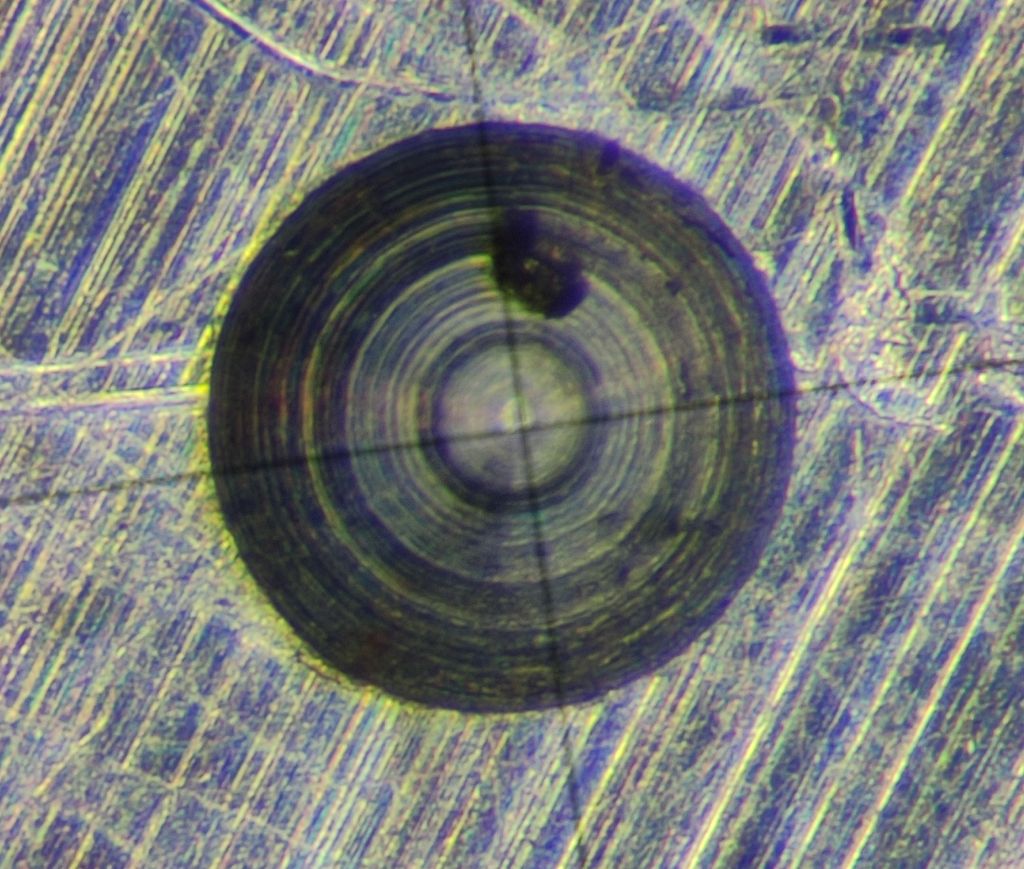

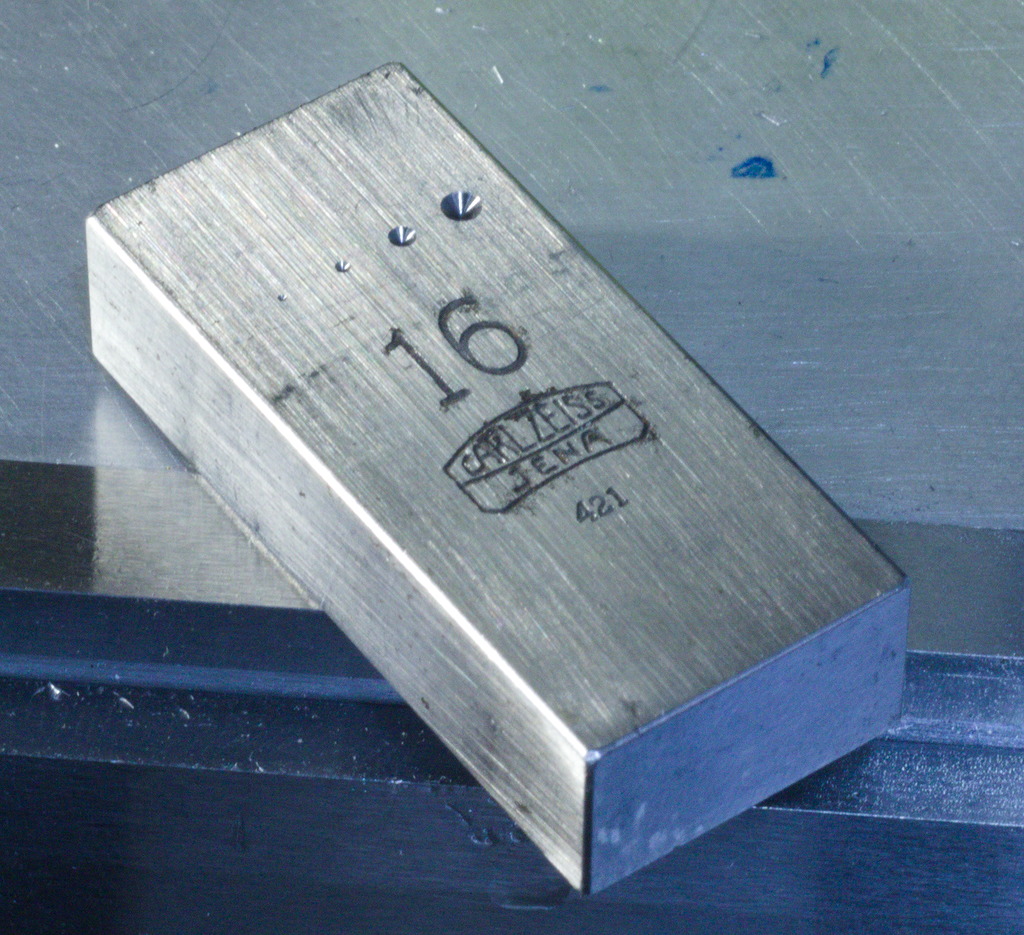

Spotting in hardened steel, an Old Carl Zeiss gage block:

Even in hardened steel, the pyramid drill leaves a very good center with minimal burr – Its amazing how well the unconventional geometry of the tool cuts almost all common materials.

Spott drilled stainless steel workpiece:

Conclusion?

This type of tool does not seem to be very well known, but it is sure worth giving it a try, if you have the capability of grinding them yourself.

Danny Rudolph mentioned these a few times in posts on Instagram, if you go back far enough in his posts.

https://www.instagram.com/dannyrudolph

Thank you, Danny, for making me aware of this tool.

One thing you, the reader, might ask: A 90° spot drill is problematic for carbide drills, since the tip angles don’t match up, right?

That’s at least the common conception, but with micro drilling it seems to be less of a problem. Getting a center/spot that’s small enough for a micro drill is already hard enough and on such a small scale there’s more effects at play – The drill might vibrate for a very short period when touching the spot before calming down and actual cutting. This can be observed with a video microscope very well.

The issue is, with a larger tip angle, this style of tool starts to cut less well, since the included angle between the clearance and the top rake surface get bigger and bigger therefore more and more negative, requiring bigger force to make the tool cut well.

90° Spotting angle: 78.5° included angle

118° Spotting angle: 96.5°included angle

If you want to give a 118° version a try, here is the angle to be ground onto the pyramid:

Despite that, give them a try, I think you will not be disappointed – It has become one of my absolute favorite tools – Simple and very reliable.