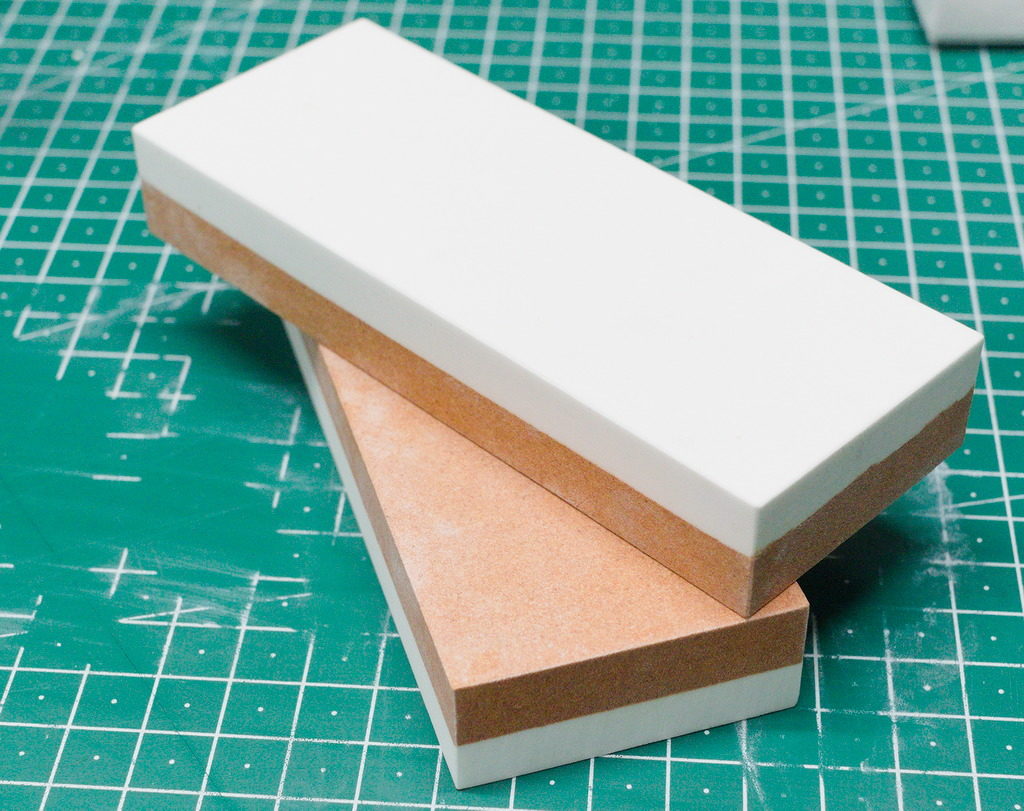

These are aluminum oxide stones in various shapes that are ground to a high degree of flatness. They are sold as a pair (See application notes). Their main use is to check and repair precision surfaces – The flatness of the stones does not allow the stones to cut into a flat surface, the surfacepressure is to low, but if there is raised material like a burr, the reduced area of contact will make the stone cut and remove the material that’s raised above the surrounding surface.

This process will not alter milled, ground and lapped surface finishes if done with care.

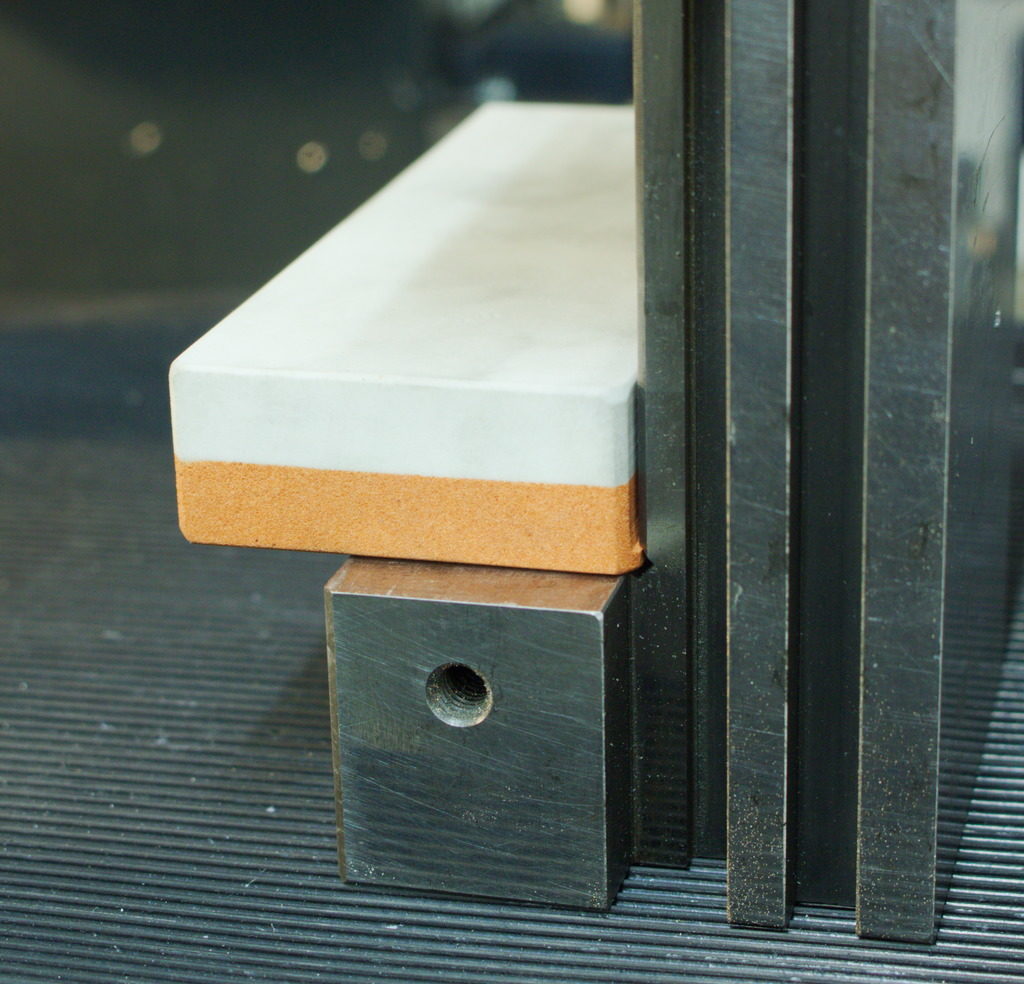

Main applications are magnetic chucks, v-blocks, vices, parallels, precision parts during assembly, external spindle tapers (Hardinge tapernose, DIN shorttaper or the tapernose of a surface grinder).

Especially useful for deburring a freshly scraped surface.

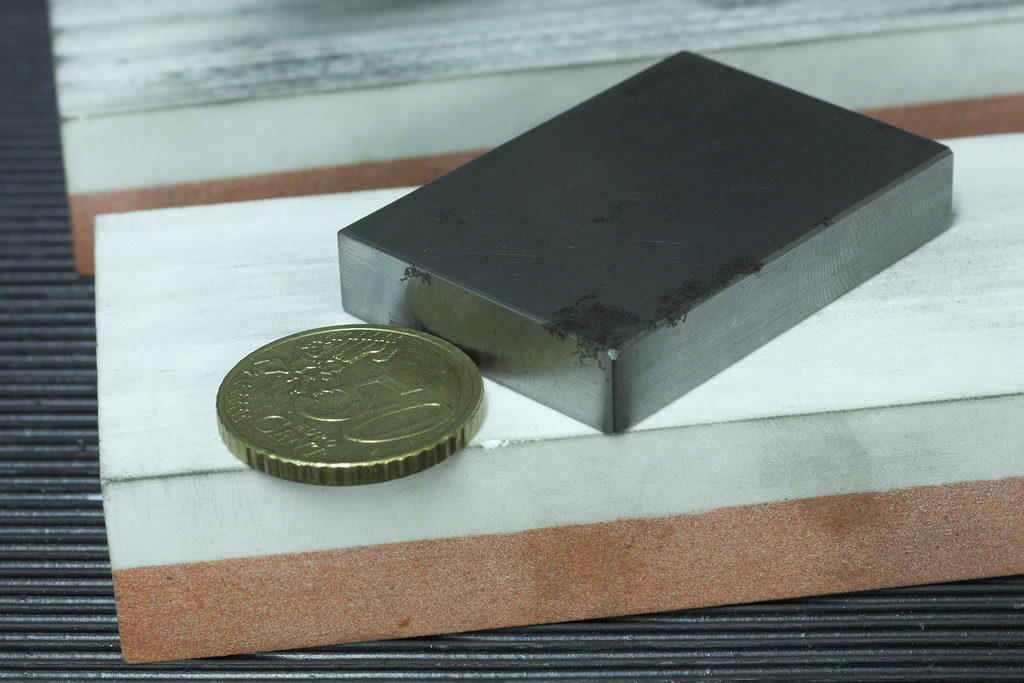

The stones come in a pair, and before each use they are rubbed against each other to remove any metal or abrasive particle that is sticking out the ground surface.

Then they can be applied to any clean precision surface and used like a regular stone to remove burrs and raised material.

They will – if used properly – Not scratch a surface, remove material or create a grind lay.

In fact, they can improve the finish of a surface almost to gage quality, as demonstrated on this worn gageblock:

They are supplied in different shapes:

- Rectangular

General use - Rectangular with one lip

General use, the lip allows to stone into the reliefcut on a vicejaw or the fence of a magnetic chuck - Rectangular with 45° Bevel

General use, the bevel allows to work into dovetails that have an angle larger than 45° - Knife edge

10° tapered stone with two ground surfaces, used to get into very narrow areas. Also for dovetails.

Application notes:

- Always use the stones dry.

- Never use any kind of liquid media like petroleum when stoning precision surfaces. The liquid will create an abrasive slurry and definitely scratch and cut into the surface you are stoning. Also make sure the surface you are planning to stone is clean and free of oil and grease.

- Before each use, rub the stones against each other until they slide perfectly smooth against each other. This ensures that any loose grit or embedded metal particle gets removed or sheared flush with the surface of the stone. This should repeated each time the stone gets placed on a new surface that needs to be stoned. This ensures that precision surfaces are not scratched or altered in any way by the stone.

- When stoning a surface, pay close attention how the stone behaves. If there is a burr or raised material, the stone will start to cut. This can be noticed by an increase of force needed to move the stone. Stone the affected area until the stone slides free without any drag on the surface. When you look at the surface you will see the shiny bright area where the raised material has been removed.

- When stoning high value items, absolute care has to be taken, cleanliness is a must, otherwise the surface can very easily damaged by loose particles.

- Round parts can be stoned while rotating under power (Good example: Cleaning up a tapershanked toolholder held in a lathe). Care has to be taken not to apply the stone to long and with even pressure. Due to the reduced contact area the stone will cut slightly more aggressive than on a flat surface.

- The stones do not have to be cleaned on a regular base, as they are only used on clean parts and surfaces. If they are very dirty or contaminated with oil/grease, they can be rinsed and whipped off with denatured alcohol or washed with a bristle brush, dish soap and water. If very large metal particles get embedded in the surface they can be picked out with a needle.

- The stones are not supposed to be used to sharpen tools or deburr parts. The small contact area on these operations will wear the stone and compromise the flatness.

Downloads

How to order

Email with name, adress (and company name / VAT Number): werkstatt@gtwr.de

Prices (Always for a pair of stones):

Rectangular stones with/without lip: 89,25Eur

Stones with 45° bevel: 101,15Eur

Knife edge stone 10°: 95,20Eur

Shipping outside Germany, within the EU (via DHL): 15Eur

(All prices including 19% VAT.)

Currently, until further notice, I can not process orders to the UK (20.01.2020)

Payment after delivery (Within 14 days via bank transfer or PayPal)

Usual delivery time is two weeks, as the stones are ground to order

No sale outside the European Union.